Diaphragm Accumulator

Introduction

The diaphragm accumulator is constructed by combining two hemispherical shells together, and a rubber diaphragm is set between these two halves to separate gas and fluid. Our product shows an extremely small weight to volume ratio, and it is very sensitive. So, it can offer remarkable performance when dampening pulsation in low pressure hydraulic lines. Meanwhile, the rubber diaphragm has a small area, which means gas expansion is limited. As a result, the gas precharge pressure couldn't be too high, and the effective volume is not too big.

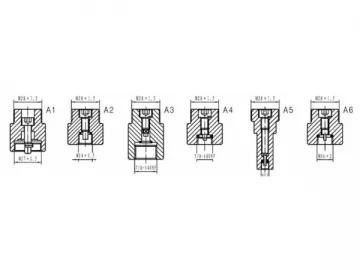

Classification

As shown in the above pictures, this diaphragm accumulator could be divided into two types which are welded type and threaded type. The welded version is featured by low cost, and the advanced high frequency electric beam welding machine realizes narrower and smoother welding seam, greatly improving product quality and appearance. However, the threaded version is repairable, and its diaphragm could be replaced. Thus, it could be used repeatedly.

Applications

With simple structure, this product is convenient for installation. It is famous for its pulsation dampening performance, and here are two cases. This product is famous for its pulsation dampening performance, and here are two cases.

1. In wind power generation industry, the yaw brake is a hydraulic control system with multi actuating mechanisms. As we know, the start up of hydraulic pump may get delayed sometimes, and the system pressure will drop when one actuating mechanism starts, leading to the reduction of braking torque of the mechanical brake. So, braking effect is deteriorated. If a sensitive diaphragm accumulator is installed, the pressure fluctuation for the entire system will be reduced to a large extent, thus ensuring the normal working state of the yaw brake.

2. Aside from the above, this product is also widely accepted by different parts of engineering or mining machinery, such as drive and suspension systems of a forklift, hydraulic systems of yard cranes and stone crushers, etc. When these machines are working, drastic mechanical vibration will be generated, and our diaphragm accumulator is used to effectively absorb the pressure fluctuation that is caused by mechanical vibration. In this way, the pipes and other parts of the hydraulic system will be well protected from damage, resulting in a prolonged service life for the equipment.

| Nominal volume range | 0.16-10L |

| Nominal pressure | 10Mpa, 21Mpa, 31.5Mpa |

| 100Bar, 210Bar, 330Bar, 350Bar | |

| Fluid port connection | Metric thread N: NPT thread S: SAE thread G: BSP thread |

| Gas valve | M28×1.5 |

| Working medium | Hydraulic oil, water, emulsion |

Model Explanation

GXQ A-1.6 / 10-L-R

1 2 3 4 5 6

1. Code: GXQ stands for diaphragm accumulator conforming to Chinese national standard

2. Structure: Type A/B/C

3. Nominal volume in liter

4. Nominal pressure in Mpa

5. Connection type: M for metric thread, G for BSP thread, N for NPT thread, S for SAE thread

6. Working media: Y for hydraulic oil, R for emulsion, H for water

For example, for a diaphragm accumulator that is characterized by 10Mpa nominal pressure, 1.6L nominal volume, type A structure, metric thread connection and working medium of water, it should be named as GXQ A-1.6/10-M-H.

Dimensions

| Type A | Type C |

Table 1: Type A with Nominal Pressure of 6.3/10/20/31.5Mpa

| Nominal volume (L) | Max flow rate (L/min) | Dimensions (mm) | Weight (kg) | ||||||

| d0 | d1 | d2 | d3 | d4 | H | n-M | |||

| 0.4 | 60 | M27×1.5 | M18×1.5 | 100 | 120 | 130 | 166 | 2-M6 | 4 |

| 0.63 | 95 | M22×1.5 | 120 | 135 | 150 | 160 | 4-M8 | 6.3 | |

| 1 | 139 | 155 | 170 | 176 | 5 | ||||

| 1.6 | 150 | M27×2 | 160 | 170 | 190 | 202 | 7.85 | ||

| 2.5 | 172 | 192 | 208 | 215 | 12.1 | ||||

Table 2: Type C with Nominal Pressure of 6.3/10/21Mpa

| Nominal volume (L) | Max flow rate (L/min) | Dimensions (mm) | Weight (kg) | ||||||

| d0 | d1 | d2 | d3 | H1 | H2 | H | |||

| 0.32 | 1.6 | M28×1.5 | 3/4-16 UNF | 93 | 23 | 21 | 137 | 1.3 | |

| 0.6 | 115 | 172 | 3.3 | ||||||

| 0.75 | 121 | 168 | 2.8 | ||||||

| 1 | 136 | 181 | 3.6 | ||||||

| 1.4 | 145 | 194 | 3.9 | ||||||

| 2 | 2.5 | 1 1/16-12 UNF | 160 | 211 | 4.0 | ||||

| 2.8 | 167 | 271 | 8.2 | ||||||

Ordering Details

We could provide customers with various diaphragm accumulators, and please look up in the parameter list to determine the desired parameters including nominal volume, working pressure, working medium, thread dimensions for gas port and fluid port, etc.

Related Names

Suction Accumulator | Hydraulic Energy Storage Device | Pneumatic Accumulator

Links:https://www.globefindpro.com/products/82177.html

-

Magnetic Hook

Magnetic Hook

-

Bladder Accumulator

Bladder Accumulator

-

Magnetic Button

Magnetic Button

-

Hydraulic Accumulator Repair Tool

Hydraulic Accumulator Repair Tool

-

Hydraulic Accumulator Safety Valve

Hydraulic Accumulator Safety Valve

-

FPU Hydraulic Accumulator Charging Kit

FPU Hydraulic Accumulator Charging Kit

-

Ricardo Powered Diesel Generator Set

Ricardo Powered Diesel Generator Set

-

Wudong Powered Diesel Generator Set

Wudong Powered Diesel Generator Set

-

Christmas Tree

Christmas Tree

-

High Voltage Generator Set

High Voltage Generator Set

-

Yangdong Powered Diesel Generator Set

Yangdong Powered Diesel Generator Set

-

Marine Generator Set

Marine Generator Set