Brake Disc

| Commercial Vehicle brake disc 1 | Commercial Vehicle brake disc 2 | Passenger brake disc 1 | Passenger brake disc 2 |

| Passenger brake disc 3 | Passenger brake disc 4 | Race brake disc 1 |

We have 6-year experience in manufacture and sales of the brake disc, our products are mainly focused on passenger cars and heavy duty vehicles. The annual output is more than 5,000 tons, all of which are exported to over 20 countries around the world! These achievements are conducted by our unremitting pursue of quality and credit.

Advantages

We strictly abide by TS16949 automotive industry quality management standard in every step, from material suppliers selection, material examinations and inventory management to manufacturing procedures, products tests and logistics. Therefore, our products have ensured quality and trueness.

Manufacturing Techniques

Our brake disc for heavy duty vehicles use sand casting process, whereby the quality is enhanced, and the production cycles are shortened.

Manufacturing Equipment

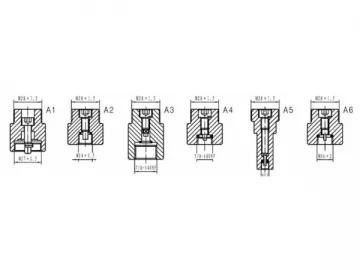

CNC (Computer Numerical Control) machining ensures extremely smooth surface and guarantee perfect parallelism and flatness. All products are through dynamic balance test for minimization of brake wobble and noise.

Examinations

We apply various material analysis and mechanical capacity testing equipment such as Carbon silicon analyzer, spectrometer as well as metallographic examination instrument, whereby the 5 chemical elements (C, Si, P, Mn, S) adhere to perfect matching tolerance, and the tensile force is ensured to be above 210Mpa. Meanwhile, the hardness is HBS187-241 so as to enhance crank resistance. After being strictly tested, we clean our brake discs and ensure rust resistance capacity before presenting to customers.

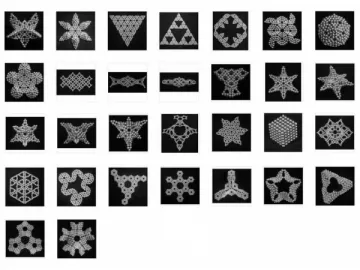

In order to meet customers' requirements on new products, we are capable of manufacturing in accordance with specific requests. It is suggested that specific details are supplied on the basis of referring to pictures showed below. And these details include your requirements on dimensions, materials, ventilation slots configurations, as well as casting process and surface.

Types

As for the brake disc for heavy duty vehicles, we have more than 300 kinds, covering most autos all over the world, such as BPW (Europe's leading axle and suspension manufacturer) , DAF, Iveco, MAN, Mercedes-Benz, SAF (Swedish car manufacturer), Scania and Volvo.

Our products for passenger cars also are applicable to most auto brands such as BMW, Mercedes-Benz, Honda, Toyota, GM, Hyundai and Daewoo, etc.

Besides, we apply the cold box core shooter, fully automotive molding line and advanced on-line testing equipment to control the refined process and fulfill the requirements on balance and engrave. And we have invented drilled and slotted brake discs to meet different needs from customers.

Drilled and slotted discs, namely, are the discs applied the drilling and slotting treatments. This increases friction coefficient, whereby promotes brake efficiency. Besides, these slots and grooves can not only gather attached dirt, but also improve cooling effect and lighten discs. In addition, we can judge degree of wear by the depth of grooves.

Production Flowchart

| Casting 1 | Casting 2 | Machine 1 |

| Machine 2 | Inspect | Clean and Packing |

Related Names

Truck Brake Parts | Automobile Brake Rotor | Front Brake Discs

Links:https://www.globefindpro.com/products/82189.html

-

Brake Pad Sensor

Brake Pad Sensor

-

Flexible Magnetic Sheet

Flexible Magnetic Sheet

-

Neodymium Magnetic Toys

Neodymium Magnetic Toys

-

Hydraulic Oil Filter Vehicle

Hydraulic Oil Filter Vehicle

-

Hydraulic Component Testing Centre

Hydraulic Component Testing Centre

-

Industrial Hydraulic System

Industrial Hydraulic System

-

Nitrogen Gas Bottle

Nitrogen Gas Bottle

-

Accumulator Combination

Accumulator Combination

-

Cabin Filter

Cabin Filter

-

FPU Hydraulic Accumulator Charging Kit

FPU Hydraulic Accumulator Charging Kit

-

Hydraulic Accumulator Safety Valve

Hydraulic Accumulator Safety Valve

-

Hydraulic Accumulator Repair Tool

Hydraulic Accumulator Repair Tool