Alnico Magnet

The alnico magnet is an alloy composed of aluminum, nickel, cobalt, iron and other trace metals. The component percentage of the metal elements determines the magnetic properties and the applications of the product.

There are two manufacturing methods, casting and sintering. Through casting, alnico magnet of different sizes and shapes can be obtained. The sintered product is relatively small in size, but its dimensional tolerance is less than that of the cast product.

The alnico magnet has the lowest reversible temperature coefficient among all magnets and its operating temperature can reach 500℃ and higher. It is widely used in the teaching, aviation, electronic, automobile, electromechanical, medical treatment, military technology, and other fields.

Our products are mainly sold to auto parts manufacturers in the US and Germany. We have established a good and stable cooperative relationship with BOSCH and other world-renowned enterprises. If you have any questions or needs, please feel free to contact us.

Applications

| Drawing | Description | Applications |

| D×d×t | Motors, meters, odometers, etc. | |

| D×L | Speakers, sensors, etc. | |

| L×W×H | Telephones, mobile phones and others. |

Production Flow of the Cast Alnico

Technical Specifications of Cast Alnico Magnet

| Grade | Remanence (Br) | Coercive Force (Hcb) | Maximum Magnetic Energy Product (BH)max | Density (D) | Equivalent MMPA Class | Temperature Coefficient (αBr) %/℃ | Curie Temperature (TCr) | Operating Temperature (Tw) | ||||

| mT | Gs | KA/m | Oe | KJ/m3 | MGOe | g/cm3 | Near Br | Near Hcj | ℃ | ℃ | ||

| *LN9 | 680 | 6800 | 30 | 380 | 9.0 | 1.13 | 6.9 | Alnico3 | -0.03 | -0.02 | 810 | 450 |

| *LN10 | 600 | 6000 | 40 | 500 | 10.0 | 1.20 | 6.9 | -0.03 | -0.02 | 810 | 450 | |

| *LNG12 | 720 | 7200 | 45 | 500 | 12.4 | 1.55 | 7.0 | Alnico5 | -0.03 | -0.02 | 810 | 450 |

| *LNG13 | 700 | 7000 | 48 | 600 | 12.8 | 1.60 | 7.0 | |||||

| LNG37 | 1200 | 12000 | 48 | 600 | 37.0 | 4.65 | 7.3 | Alnico5DG | -0.02 | 0.02 | 860 | 525 |

| LNG40 | 1250 | 125000 | 48 | 600 | 40.0 | 5.00 | 7.3 | |||||

| LNG44 | 1250 | 125000 | 52 | 650 | 44.0 | 5.50 | 7.3 | |||||

| LNG52 | 1300 | 13000 | 56 | 700 | 52.0 | 6.50 | 7.3 | Alnico8 | ||||

| LNG60 | 1350 | 13500 | 59 | 740 | 60.0 | 7.5 | 7.3 | Alnico5-7 | ||||

| LNGT28 | 1000 | 10000 | 58 | 720 | 28.0 | 3.50 | 7.3 | Alnico6 | -0.02 | 0.03 | 860 | 525 |

| LNGT36J | 700 | 7000 | 140 | 1750 | 36.0 | 4.50 | 7.3 | Alnico8HC | -0.025 | 0.02 | 860 | 550 |

| *LNGT18 | 580 | 5800 | 100 | 1250 | 18.0 | 2.2 | 7.3 | Alnico8 | -0.025 | 0.02 | 860 | 550 |

| LNGT32 | 800 | 8000 | 100 | 1250 | 32.0 | 4.0 | 7.3 | Alnico8 | -0.025 | 0.02 | 860 | 550 |

| LNGT40 | 800 | 8000 | 110 | 1380 | 40.0 | 5.0 | 7.3 | |||||

| LNGT60 | 900 | 9000 | 110 | 1380 | 60.0 | 7.50 | 7.3 | Alnico9 | -0.025 | 0.02 | 860 | 550 |

| LNGT72 | 1050 | 10500 | 112 | 1400 | 72.0 | 9.00 | 7.3 | |||||

Note: "*" represents that material is isotropic; others are anisotropic.

Related Names

High Temperature Magnet | Rod Magnets | Horseshoe Magnet

Links:https://www.globefindpro.com/products/82214.html

-

Stainless Steel Bottle Opener

Stainless Steel Bottle Opener

-

Stainless Steel Salt and Pepper Mill

Stainless Steel Salt and Pepper Mill

-

Holding Magnet

Holding Magnet

-

Stainless Steel Ice Bucket

Stainless Steel Ice Bucket

-

Stainless Steel Tissue Box

Stainless Steel Tissue Box

-

Stainless Steel Medicine Chest

Stainless Steel Medicine Chest

-

Stainless Steel Hip Flask

Stainless Steel Hip Flask

-

Stainless Steel Oil Can

Stainless Steel Oil Can

-

Stainless Steel Canister

Stainless Steel Canister

-

Stainless Steel Kitchen Accessories

Stainless Steel Kitchen Accessories

-

Fridge Magnet

Fridge Magnet

-

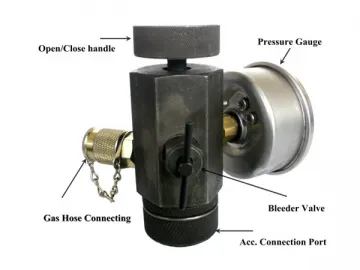

PC Hydraulic Accumulator Charging Kit

PC Hydraulic Accumulator Charging Kit