RBL1600P/2000P/2500P Automatic Glass Sandblasting Machine

The automatic glass sandblasting machine has three models, RBL1600P, RBL2000P and RBL2500P. It is scientifically designed to process flat glass with thickness of 5-50mm for steric patterns, and the sandblasting height and width can be adjusted depending on the practical application.

Features

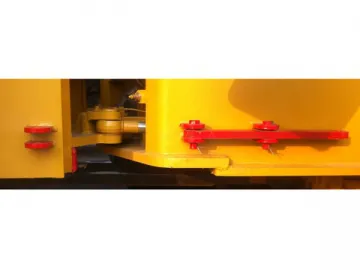

1. This product contains two working modes which are automatic mode and manual mode, and it is equipped with three automatic spray guns and one handheld spray gun.

2. The spray gun movements and the glass delivery are driven by the timing belt which features stable transmission, high efficiency, easy maintenance and long service life.

3. The lifting device for spray gun is set outside the machine, which not only lowers failure rate, but also brings great convenience to daily maintenance.

3. The sandblasting speed reaches up to 20-30m2/h, and the sandblasting depth can be customized.

4. Our automatic glass sandblasting machine offers uniform sandblasting result, and simple operation is realized as a result of the human-machine interface and PLC control system.

Technical Parameters

| Model | RBL1600P | RBL2000P | RBL2500P |

| Max. glass height (mm) | 1600 | 2000 | 2500 |

| Min. glass size (mm) | 200×200 | 200×200 | 200×200 |

| Glass thickness (mm) | 5-50 | 5-50 | 5-50 |

| Transfer speed (m2/h) | 12-15 | 12-15 | 12-15 |

| Total power (kW) | 3.5 | 3.5 | 3.5 |

| Overall size (mm) | 4700×1500×2300 | 6800×1500×2800 | 6800×1500×3300 |

| Weight (kg) | 1300 | 1500 | 1500 |

| Power supply | 380V / 50Hz | 380V / 50Hz | 380V / 50Hz |

Machine Structure

This automatic glass sandblasting machine mainly consists of nine parts which are input subframe, input guide rail, frame, bracket bar, main body, output guide rail, output subframe, dust catcher and air filter.

1. The input subframe is used to support the input guide rail and fasten the frame.

2. The input guide rail delivers the glass to the main body.

3. The frame is connected to the bracket bar to support glass panels, avoiding backward movement of glass panels.

4. The bracket bar is designed to support the glass firmly.5. The main body is meant to finish the processing step, and it can also control the normal running of this product.

6. The output guide rail is used to transport the processed glass panels.

7. The output subframe supports the output guide rail and fastens the frame.

8. The dust catcher removes dust generated during working.

9. The air filter is responsible for providing purified compressed air.

Major Components

| Item | Descriptions |

| Main electrical components | Siemens or CHINT Electronics Co., Ltd. |

| PLC | Mitsubishi, Japan |

| Touch screen | Samkoon Automation Technology (Shenzhen) Company Limited |

| Machine frame | It is fabricated by high quality thickened steel, and high temperature annealing treatment is also applied. It has a stable structure which makes it capable of handling large working load. |

| Timing transducer | Emerson, USA |

| Pneumatic parts | Zhejiang Hengyi brand |

| Bearing | HRE: Harbin Ruiha Beaing Co., Ltd. |

| Photoelectric switch and intermediate relay | Omron, Japan |

| PLC | Delta, Taiwan |

| Human-machine interface | Hitech, Taiwan |

| Rotary encoder | Elco, Switzerland |

| 2.2kW blower | Foshan Rongyi brand |

| Air drying machine | DBL brand |

Packing Size and Weight

| Product | Model | Packing size (mm) | Net weight (kg) | Gross weight (kg) |

| Automatic glass sandblasting machine | RBL1600P | 2800×1650×1900 | 1,300 | 1,350 |

| RBL2000P/2500P | 4000×1800×2500 | 1,500 | 1,550 |

Related Names

Glass Bead Blasting Equipment | Industrial Glass Process Equipment | Sand Blaster

Links:https://www.globefindpro.com/products/82417.html

-

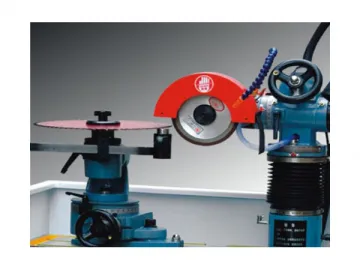

Circular Saw

Circular Saw

-

XD950G 5T Wheel Loader

XD950G 5T Wheel Loader

-

RQG2520A/4028A Automatic Glass Cutting Machine

RQG2520A/4028A Automatic Glass Cutting Machine

-

RBL9325B Glass Straight Line Edging Machine

RBL9325B Glass Straight Line Edging Machine

-

RMD2719B Universal Grinder

RMD2719B Universal Grinder

-

XD930G 1.2T High Dump Bucket Loader

XD930G 1.2T High Dump Bucket Loader

-

RMZ73212B Double Lines Boring Machine

RMZ73212B Double Lines Boring Machine

-

RQG2621/3526 Semi-Auto Glass Cutting Machine

RQG2621/3526 Semi-Auto Glass Cutting Machine

-

XD926G 2T Log Grabber

XD926G 2T Log Grabber

-

Ripper

Ripper

-

XD926G 1T High Dump Bucket Loader

XD926G 1T High Dump Bucket Loader

-

RMD2720 Universal Grinder

RMD2720 Universal Grinder