Single Screw Extruder

| Equipment back side | Single screw extruder | Single screw extruder |

| Single screw extruder | Single screw extruder | Single screw extruder |

| Single screw extruder | Single screw extruder | PLC single screw plastic extruder |

| SJ single screw plastic extruder | Single screw extruder |

Designed for PP and HDPE pipe extrusion, the single screw extruder provides top performance in terms of productivity and melt homogeneity. In addition to corrugated pipe extrusion, this plastic extrusion machine can also be utilized to produce diversified products by fitting with different types of extrusion die and auxiliary equipment.

While using a proven modular structure design, we also offer varied options to meet our clients’ individual demands and fulfill their specific requirements with custom extrusion solutions. With the latest screw design, the single screw extruder offers high output that was previously reserved for larger models of equipment. This provides extrusion parts manufacturers with significant advantages in space requirements.

Due to optimized screw design, the single screw extruder reaches utmost productivity with low melt temperature and optimized melt homogeneity. Hence, it produces superior quality extrusion parts with very low energy consumption, and features outstanding throughput figures in relation to capital investment.

The screw and barrel of our extruder are extremely durable, thanks to the quality 38CrMoAIA raw material, nitrogen treatment, as well as the Ni60 coating for screw surface and barrel discharging end.

International famous brand electrical components are adopted for maximized stability, minimized failure rate, and the lowest energy consumption. They include Schneider air switches, FUJI or ABB variable frequency drives, RKC temperature control meters from Japan, as well as Siemens contactors and electrical motors. International Warranty Service for them ensures easy access to professional technical supports as well as convenient replacement and maintenance worldwide.

Advantages Brought To You

Optimized performance in the extrusion of straight-walled tubes and corrugated pipes

Screw design suitable for processing of both HDPE and PP parts

Cost-efficient extrusion solution due to energy efficient AC motors

Proven quality extrusion equipment with high cost-performance

Extremely space-saving thanks to the machine with high productivity but small diameter screw

What We Offer

Screw diameter from 20mm to 200mm

Optimal throughput brought about by high screw torque

Outputs from 10kg/h to 800kg/h

Advanced technologies for the extrusion of PP or HDPE corrugated pipes and straight-walled tubes

Main Technical Specifications

| Model | SJ-20/25 | SJ-25/25 | SJ-30/25 | SJ-45/20 | SJ-45/25 | SJ-45/28 | SJ-65/20 | SJ-65/25 | SJ-65/30 | SJ-75/25 | SJ-90/25 | SJ-90/30 | SJ-90/34 | SJ-120/25 | SJ-120/30 | SJ-150/25 | SJ-150/30 | SJ-170/25 | SJ-170/30 | SJ-200/25 | SJ-200/30 |

| Length/diameter ratio | 25/1 | 25/1 | 25/1 | 20/1 | 25/1 | 28/1 | 20/1 | 25/1 | 30/1 | 25/1 | 25/1 | 30/1 | 34/1 | 25/1 | 30/1 | 25/1 | 30/1 | 25/1 | 30/1 | 25/1 | 30/1 |

| Motor power (kw) | 2.2 | 3 | 3 | 5.5 | 7.5 | 11 | 18.5 | 22 | 45 | 37 | 55 | 90 | 110 | 90 | 110 | 132 | 160 | 200 | 250 | 315 | 355 |

| Heating power (kw) | 2 | 2 | 4 | 6 | 8 | 9 | 12 | 14 | 18 | 35 | 35 | 38 | 40 | 60 | 72 | 76 | 96 | 112 | 120 | 140 | 150 |

| Screw speed (r/min) | 10-100 | 10-100 | 10-100 | 10-100 | 8-80 | 10-100 | 8-80 | 10-100 | 10-120 | 10-100 | 10-100 | 9-90 | 9-90 | 9-90 | 9-90 | 880 | 8-80 | 8-80 | 8-80 | 7-70 | 7-70 |

| Output (kg/h) | 10 | 16 | 20 | 35 | 45 | 55 | 60 | 80 | 110 | 120 | 180 | 240 | 280 | 350 | 400 | 450 | 500 | 680 | 760 | 800 | 800 |

Links:https://www.globefindpro.com/products/82639.html

-

Plastic Crusher

Plastic Crusher

-

Plastic Mixer

Plastic Mixer

-

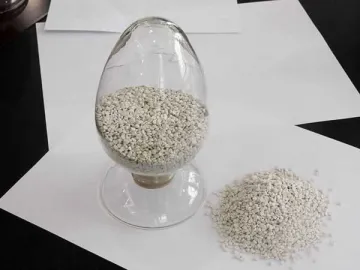

CA30 Particle / Masterbatch for Sheet Extrusion

CA30 Particle / Masterbatch for Sheet Extrusion

-

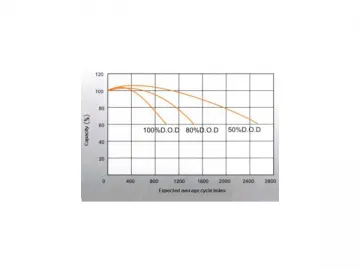

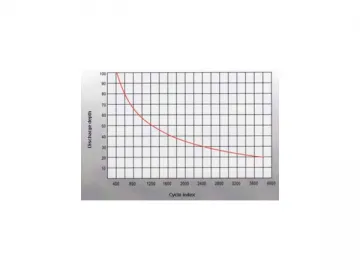

Gel Motorcycle Battery

Gel Motorcycle Battery

-

Tubular Plate Gel Golf Cart Battery

Tubular Plate Gel Golf Cart Battery

-

PVC/PE/PP Granulation Line

PVC/PE/PP Granulation Line

-

Plastic Conveyor and Cutting Machine

Plastic Conveyor and Cutting Machine

-

Flat Plate Gel Golf Cart Battery

Flat Plate Gel Golf Cart Battery

-

Other Extruder Parts

Other Extruder Parts

-

TA52 Particle / Masterbatch for Profile Extrusion

TA52 Particle / Masterbatch for Profile Extrusion

-

WPC Extrusion Line

WPC Extrusion Line

-

PVC Profile Extrusion Line

PVC Profile Extrusion Line