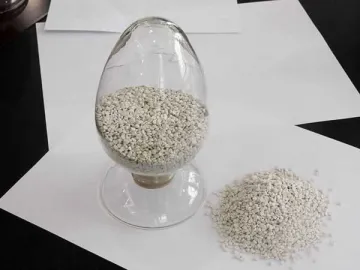

Talc Filler Masterbatch

Characteristics

1. The talc filler masterbatch can increase production efficiency and reduce production costs. It has good dispersion, and excellent compatibility with polyethylene, so that it can strengthen the tension of polyethylene blown film.

2. The material offers good printability and permeability to the film products. With no dust overflow, the usage amount of the white masterbatch can be reduced.

3. The finished product in waste recycling heap burns quickly with no oil dripping, causing no damage to the incinerator.

| Model | Melt index | Whiteness | Density | Mineral fineness | Recommended adding proportion | Application | |

| Film blowing | Plastic blowing | ||||||

| TA52 | 1.0-5.0 | ≥ 85 | 1.67-1.71 | 800 | 10-40% | 10-30% | Rolling bags, shopping bags, garbage bags, etc. |

Remark:The TA52 talc filler masterbatch is suitable for high-end transparent LDPE film blowing.

FM is a specialized talc filler masterbatch manufacturer and supplier in China. Our company offers a vast range of products, including non woven fabric masterbatch, particle / masterbatch for pipe extrusion, injection molding masterbatch, among others.

Related Names

Additive for High Efficiency PE Blowing Film Production | High Quality Blowing Film Making Solution | Printable Film Manufacturing Compound

Links:https://www.globefindpro.com/products/82648.html

-

Conical Twin Screw Extruder

Conical Twin Screw Extruder

-

PVC/PE/PP Pipe Extrusion Line

PVC/PE/PP Pipe Extrusion Line

-

Casting Film Masterbatch

Casting Film Masterbatch

-

PE/PP Recycling Line

PE/PP Recycling Line

-

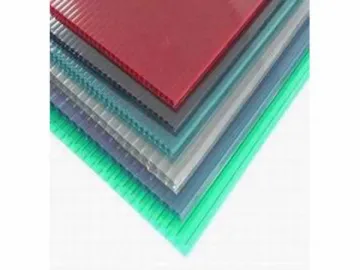

PE81 Particle / Masterbatch for Hollow Sheet Extrusion

PE81 Particle / Masterbatch for Hollow Sheet Extrusion

-

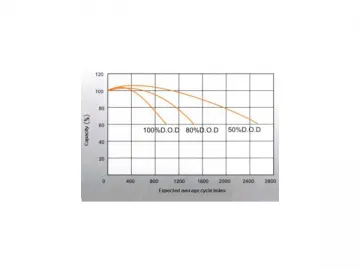

VRLA Battery (Valve-regulated Lead-acid Battery)

VRLA Battery (Valve-regulated Lead-acid Battery)

-

High Performance Dry-Charged Motorcycle Battery

High Performance Dry-Charged Motorcycle Battery

-

PVC/PE/PP Granulation Line

PVC/PE/PP Granulation Line

-

Tubular Plate Gel Golf Cart Battery

Tubular Plate Gel Golf Cart Battery

-

Gel Motorcycle Battery

Gel Motorcycle Battery

-

CA30 Particle / Masterbatch for Sheet Extrusion

CA30 Particle / Masterbatch for Sheet Extrusion

-

Plastic Mixer

Plastic Mixer