Rotary Grading Sieve

| Model | Output | Power (kW) |

| SFJH80×1d | 5 | 1.50 |

| SFJH100×1d | 10 | 2.20 |

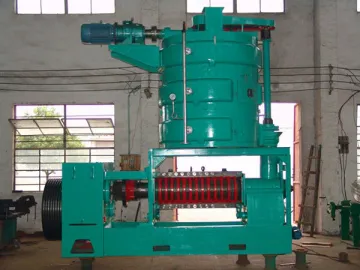

The SFJH series vibratory rotary grading sieve is responsible for the last procedure of the pelleting section. After being molded and cooled, the powder material will be processed by the grading device to extract qualified products. Meanwhile, the unqualified pellets or powder will be screened out for re-granulation.

Main Construction

Our rotary grading sieve is primarily made up of vibration motor, screen body and cloth, high strength spring as well as other components. It is powered by the vibration motor and supported by the spring. Therefore, this grading equipment is characterized by steady running, little noise and low requirements for strength of upholders. As the screen cloth comes with a cleaning device, this filtering unit boasts great yield, exceptional screening effects but low power consumption.

Working Principle

The rotary grading sieve filters materials in line with the particle size. Accordingly, it must be designed with the appropriate holes and relative movement speed to make materials in full contact with the screen cloth. During filtering process, the material whose size is larger than that of screen hole can not pass through the hole, so it is called screen overflow. By contrast, the one with size smaller than that of the screen hole is able to travel through the hole, so it is named as screen underflow.

KMEC is a professional rotary grading sieve manufacturer and supplier in China. We provide a broad range of products, including steam cooking equipment, pellet press machine, auto packing machine, grain destoner, and much more.

Related Names

Rotary Vibratory Sieve | Grading Equipment

Links:https://www.globefindpro.com/products/82827.html