Miscella Treatment (Solvent Oil), Evaporating, Stripping

Treatment Process

The solid fines in the miscella are separated via filtration and sedimentation. The solvent is separated from oil in line with their different boiling points by evaporating and stripping the miscella. After a series of treatment, the fines can be thoroughly removed. Meanwhile, the solvent and oil can be fully separated from each other at a lower temperature and in a short period of time. The materials generated in the production of oil, like phospholipid, saccharides, etc., will be protected from adverse effects. Thus, the quality of leached crude oil will be improved and the heat consumption amount is reduced.

1. Long Tube Evaporator

The working principle of the long tube evaporator can be illustrated as follows. The evaporation of miscella is carried out based on different boiling points of oil and solvent. The miscella is heated to the boiling temperature so as to make solvent vaporized and separated from oil.

The boiling point of the miscella increases as the concentration grows. The boiling point of miscella with the same concentration will decrease along with the reduction of the evaporation operation pressure. The two-stage evaporation method is adopted for the miscella. The first stage evaporation can increase the mass friction of miscella to 60 to 70% from 20 to 25%. The second stage evaporation makes the mass friction of miscella reach 90% to 95%.

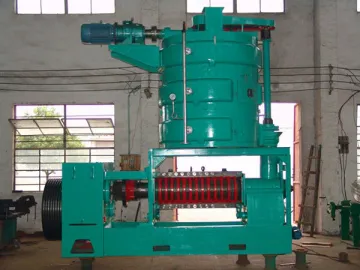

2. Disk Stripping Tower

The new type stripping tower is extremely able to remove solvent. The amount of residue solvent in the crude oil will be protected from fluctuation which may be caused by the change of steam during production. The volatile matter in the crude oil will be dramatically reduced, thus guaranteeing the secure refining of the leached crude oil. Additionally, the tower body and tray are connected with the flange, thus bringing convenience for maintenance and cleaning.

Working Principle

The steam stripping of the miscella refers to the steam distillation of miscella. It is able to lower the boiling point of high concentration miscella so that a little residue solvent in the miscella can be completely eliminated as much as possible at a lower temperature.

The solvent is removed from the oil under negative pressure, which is very conductive to the quality of crude oil. In order to ensure stripping effects, the steam to be used for stripping has to be dry. The water in the direct steam will be prevented from contacting with oil, or else the phospholipid will precipitate and the normal operation of stripping equipment will be influenced. Meanwhile, the stripping flooding problem can be effectively reduced.

As a professional miscella treatment (solvent oil), evaporating, stripping equipment manufacturer and supplier in China, KMEC provides a wide array of products, including high square sieve and flat sieving machine, counter-flow cooling machine, drying machine, diesel pellet mill, and much more.

Related Names

Evaporating Plant | Gas Stripping Tower

Links:https://www.globefindpro.com/products/82838.html