Sunflower Seeds Dehuller/Shell and Kernel Separator

1. TFKH Sunflower Seed Dehuller

The dehuller is able to get rid of various impurities in the raw sunflower seed materials as well as to unshell, peel, separate and reselect the cleaned sunflower seeds. The unhulled seeds will be automatically conveyed to the dehulling machine for secondary dehulling, thus dramatically improving the decorticating efficiency.

Our sunflower seed dehulling unit comes with the characteristics of small damage to kernel, outstanding husking and separating effects, high automation degree, as well as convenient operation and maintenance. It is an ideal solution to sunflower seeds in terms of impurity removal, dehulling and separation. The sunflower kernels processed by our dehuller can be used in food industry and oil extraction industry.

2. YBKY Round Disk Dehulling Machine

The product crushes shells of oil plants by use of crumbing effects of the rough surface. It features a simple construction coupled with convenient adjustment and use. This dehulling unit has found a wide range of applications, mostly for dehulling cottonseeds. It also suits for husking of peanuts, linseeds, etc. Additionally, this dehulling device is able to function as a crusher for oil cakes.

| Model | Processing Capacity (t/24hours) | Power (kW) | Weight (kg) | Overall Dimension (mm) |

| YBKY45 | 28 | 7.5 | 550 | 1320×600×910 |

| YBKY71 | 35 | 17 | 1100 | 1921×1004×1438 |

| YBKY81 | 48 | 22 | 1350 | 2100×1120×1500 |

| YBKY91 | 60 | 30 | 2000 | 2400×1260×1790 |

3. Rape Seed Dehulling Equipment

The rape seed dehuller is especially designed to dehull rape seeds and to separate husk from kernel. It works with double rollers to extrude, sheer and rip rape seeds. The husk and kernel separating equipment adopts vibration screening and winnowing separation methods according to bulk density of husk and kernel, as well as sieving abilities.

Features

1. The rape seed husking machine is characterized by small floor space, high yield, simple management and low labor intensity.

2. The double rollers are made up of the austempered ductile iron, a new material, and processed with special technique. Thus, they are very durable.

3. This product is equipped with a unique sieve plate, reducing the frequency to change broken screen cloth. For this reason, the working efficiency is effectively improved.

4. The winnowing system chooses the multi-machine vertical air aspiration technique, making the winnowing efficiency greatly boosted.

5. The dehulling rate is from 90% to 98% with the moisture content being 2% to 10%. Meanwhile, the rate of husk contained in kernel is from 1% to 4%.

4. Quick Soybean Fluidized Bed Dryer

The product is capable of quickly heating and drying soybeans by use of the circulating hot airflow. In this way, the content of moisture in soybean husk is reduced and the husk becomes loose. Thus, after the soybean is crushed, the husk can be easily separated from the bean kernel and the content of kernel adhering to the husk can be reduced.

The temperature of soybeans conveyed into the dryer is 60°C and the moisture content is about 10%. The thickness of material bed on the steel wire conveying belt is from 150mm to 200mm. The speed of conveying belt is approximately 127 to 381mm/min. The discharging temperature of soybean is between 77°C and 90°C.

5. Soybean Shell and Kernel Separator

The separating equipment is a kind of device used to separate soybean shell and kernel through winnowing effects made by the air stream as well as mechanical effects of an impacting rod.

Features

1. This separating machine has high separating efficiency. After the soybean husk and kernel are separated from each other, the percentage of husk in the kernel and that of kernel in the husk are both very low. When the husk and kernel are being separated, the temperature and humidity level of soybean kernel can both be regulated to make the kernel softened.

2. This winnower comes with high separation levels. As the brokensoybeans are collided with one another for many times, the husk and kernel are separated from one another, making higher the dehulling rate.

3. All the functional sections come with assembled structures, thus they are easy and convenient for installation, dismantling and maintenance.

4. This separator is equipped with fewer moving parts, so it is highly safe and reliable, as well as power efficient.

5. The handling capacity of one product is up to 25 tons per hour.

6. This product employs the circulating hot air technique which can remove some moisture in materials in an effective way while requiring little energy.

6. Peanut Shelling Machine

With reliable performance, our peanut shelling machine has earned high reputation due to its high shelling ratio and low cracking ratio. It offers clean shelled-peanuts with good color, and low impurities. The performance of our peanut sheller exceeds national standards. The shelled groundnut produced by the machine meets food grade, and is ideal material for cooling oil processing.

Technical Specifications| Model | Capacity | Shelling Ratio | Crushing Ratio | Cleaning degree | Power | Worker Required | Weight | Size |

| 6BK-400B | 400kg/h | ≥95% | ≤5% | ≥95.5% | 2.2kw/2p | 1-2 person | 127kg | 1200*660*1240mm |

| 6BK-800C | 800kg/h | ≥98% | ≤4% | ≥97.5% | 4kw/4p | 2-3 person | 330kg | 1520*1060*1660mm |

| 6BK-1500C | 1500kg/h | ≥98% | ≤4% | ≥97.5% | 7.5kw/4p | 3-5 person | 700kg | 1960*1250*2170mm |

| 6BK-3000C | 1500kg/h | ≥98% | ≤4% | ≥97.5% | 11kw/4p | 3-5 person | 850kg | 2150*1560*2250mm |

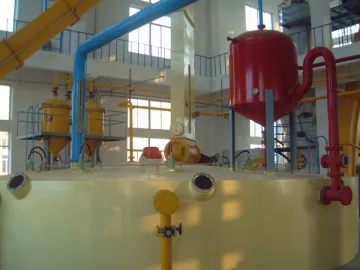

Conditioning Tower

The conditioning tower is key equipment in dehulling process. It has altogether 12 effective layers. The first layer is mainly responsible for material seal and the control of the height of material bed. The second, third and fourth layers are in charge of pre-conditioning and heating. The materials are indirectly heated by the steam via round or oval tube.

The fifth layer is used to pre-dewater materials. The materials are heated by the hot air through the horn shaped air inlet tube. The sixth, seventh and eighth layers are mainly for conditioning and heating use. The round or oval tube is adopted for indirect steam heating. The ninth and tenth layers have dewatering function with the materials heated by hot air. The eleventh and twelfth layers play an auxiliary conditioning and heating role with materials indirectly heated via steam.

The bottom of the conditioning tower is designed with 6 impellers which discharge materials side by side. For this reason, the materials can be uniformly discharged.

KMEC is an experienced seed dehuller, shell and kernel separator manufacturer and supplier in China. We also offer air aspirator and air suction channel, wheat bran finishing machine, solvent extractor, electric pellet mill, and more.

Related Names

Husking Machine | Decorticator

Links:https://www.globefindpro.com/products/82868.html