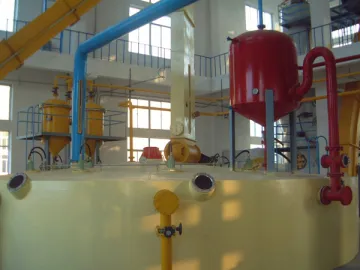

Solvent Extractor

1. Stainless Steel Fixed Grid Plate Type (Rotocel Type)

Main Construction

The stainless steel fixed grid plate solvent extractor is also called the rotocel extrusion machine. It is primarily made up of shell, rotor, fixed grid plate bottom, spray system, base, main shaft, transmission system and oil mixing hopper.

Working Principle

The material blank is delivered to each grid of the rotor by the sealed auger. On the outer ring of the rotor is the rack. The rotor rotates around the main shaft at a low speed through the transmission system. The material blank is first injected with the relatively thick miscella to extract the oil. As the extracting unit rotates, it is given with miscella whose concentration reduces successively so as to decrease oil content of the material blank. At last, the fresh solvent containing no oil is adopted to make the oil content of the material blank reduced to around 1%. In this way, the material blank is transformed into wet meal. After being drained dry, the wet meal falls into the wet meal hopper via wet meal falling port. The miscella is pumped out of the oil hopper and then transmitted to the evaporation system.

Main Features

a. The stainless steel fixed grid plate solvent extractor is the most simple kind among those advanced solvent extraction machines.

b. It makes use of a fixed grid plate instead of the false bottom, which reduces failure rate and meanwhile improves performance safety.

c. With the self-cleaning function, the grid plate can be well cleaned without stopping the whole extracting machine.

d. This solvent extracting unit is capable of increasing the solvent time of materials for further elimination of oil residual in meal.

e. It can improve loading factor so as to boost production.

f. Apart from the characteristics of low power consumption but excellent solvent effects, easy maintenance, long service life, etc., this extracting system comes with greater capacity, simpler structure and stronger performance reliability in comparison with traditional rotary solvent extraction machine.

2. Loop Type

Features

a. YJCH-Ⅲloop type solvent extractor is revised and completed via our around 20 years of efforts and has gained a wide range of popularity in oil industry.

b. The daily handling capacity is between 30 and 2500 tons.

c. The extracting machine can be assembled in our factory and then delivered to customers.

d. It can be conveniently installed on the scene, occupying small space and saving a lot of construction investment.

e. The leaching material layer is thin. The oil material is turned up and down once in the extracting machine so as to lower the content of residue oil in the meal.

f. This loop type solvent extractor comes with automatic control and adjustable running speed.

g. It boasts steady and reliable operation, as well as excellent encapsulation.

h. Oil materials are cut into several independent units on the material bed.

i. The miscella at different levels is effectively prevented from flowing among one another on the material layer, ensuring concentration gradient among different spraying processes.

j. Each independent unit is used as a solvent working area for realization of better solvent effects.

k. The chain box is supported by the rail to not contact with the sieve cover, thus prolonging the service life of the screen cloth.

l. The quality of our products is ISO certified and some parts of accessories are CE approved.

m. The solvent extracting unit is more suitable for materials with high oil content and great fines content. For common oil materials, it is able to supply more excellent leaching effects.

3. Tank Group Type

The 3T-20T/D tank group solvent extractor can be used to leach cake meal for oil. The cake meal can be made from various roughly extracted oil materials, such as vegetable seed, soya bean, cottonseed, peanut, etc. In comparison with other techniques, the tank group extracting process is characterized by more stable performance, less equipment investment, more rapid profit gains, lower power consumption, etc. This type of extracting equipment is an ideal solution for oil plants either owned by urban and rural individual or township enterprises.

KMEC is a specialized solvent extractor manufacturer and supplier in China. We offer various types of products such as flat die pellet mill (R-type), gasoline pellet mill, pneumatic flour mill, and screw conveyor.

Related Names

Solvent Extraction Plant | Liquid-Liquid Extraction

Links:https://www.globefindpro.com/products/82874.html

-

Drum Chipper

Drum Chipper

-

Oil Seed Extruder/Extruding Machine

Oil Seed Extruder/Extruding Machine

-

Oil Bleaching Process

Oil Bleaching Process

-

Flat Die Pellet Mill (R-Type)

Flat Die Pellet Mill (R-Type)

-

ZLSP-Q D-Type Gasoline Pellet Mill

ZLSP-Q D-Type Gasoline Pellet Mill

-

Cleaning Sieve, Destoner, Crusher

Cleaning Sieve, Destoner, Crusher

-

Wheat Bran Finishing Machine

Wheat Bran Finishing Machine

-

Air Flow Dryer

Air Flow Dryer

-

ZLSP-B R-Type Pellet Press Machine

ZLSP-B R-Type Pellet Press Machine

-

Oil Neutralization/Deacidification Process

Oil Neutralization/Deacidification Process

-

Ring Die Pellet Mill

Ring Die Pellet Mill

-

Sunflower Seeds Dehuller/Shell and Kernel Separator

Sunflower Seeds Dehuller/Shell and Kernel Separator