Oil Seed Extruder/Extruding Machine

Working Principle

The oil seed extruder works in line with the following procedures. The heat is generated through kneading plus friction between the spiral shaft and inner wall of the expanding machine. Meanwhile, the steam is injected so as to increase the flake temperature.

The cell tissue of oilseed is destroyed completely inside the expander. When extruded out of the expander, the oilseed with great pressure and high temperature will be expanded owing to sudden pressure relief. Additionally, the moisture in the oilseed is evaporated suddenly. For this reason, the material has a micro porous construction and the soybean is expanded into an irregular, loose and high intensity particles.

1. Small Type with Dry Extruding Method

Features

1. The small oil seed extruder is suitable for expanding full fat soybean, corn, piglet, soybean meal, cotton seed meal, rice bran, etc.

2. It will make modification for the quality of raw materials and improve digestibility.

3. The feeding device is in the charge of the FC inverter so that raw materials can be uniformly fed into the extrusion chamber.

4. The screw and barrel of the oil seed extruder are optimized for longer operation life as well as reduced production costs.

5. The lengthening conditioner makes retention full and even, thus brining out good retention effect.

6. One oil expander can be applied to a great variety of materials by changing some spare parts.

| Mode | Screw Dimension | Rotation Speed | Power (Main Motor) | Power (Feeder Motor) | Capacity |

| TXP-100 | Φ135 | 630RPM | 22kW | 1.5kW | 250~380 kg/h |

| TXP-160 | Φ155 | 600RPM | 55kW | 2.2kW | 16~24 t/day |

| TXP-165 | Φ205 | 500RPM | 75kW | 2.2kW | 25~36 t/day |

2. Large Type

Puffing Index of Oil Materials

| Article | Index (Low Oil Content, Material like Soybean) |

| Flake Thickness(mm) | 0.3~0.5 |

| Water Content Before Going to Puffing Machine (%) | 10~11 |

| Moisture Content Going Out of Puffing Machine (%) | 12~14 |

| Cake Meal Temperature After Puffing (°C) | 100~110 |

| Steam Consumption (kg/t material) | 26~28 |

| Steam Pressure(MPa) | 0.6~0.8 |

As a professional oil seed extruder/extruding machine manufacturer and supplier in China, we also provide 10-250T flour mill plant, chaff cutter, diesel pellet mill, hammer mill, and much more.

Related Names

Oil Expander | Oil Bulking Machine

Links:https://www.globefindpro.com/products/82876.html

-

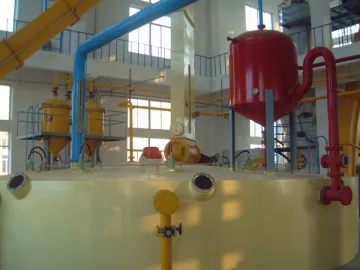

Oil Bleaching Process

Oil Bleaching Process

-

Flat Die Pellet Mill (R-Type)

Flat Die Pellet Mill (R-Type)

-

ZLSP-Q D-Type Gasoline Pellet Mill

ZLSP-Q D-Type Gasoline Pellet Mill

-

Cleaning Sieve, Destoner, Crusher

Cleaning Sieve, Destoner, Crusher

-

Beans Dehuller

Beans Dehuller

-

Oil Bottling/Oil Filling Machine

Oil Bottling/Oil Filling Machine

-

Drum Chipper

Drum Chipper

-

Solvent Extractor

Solvent Extractor

-

Wheat Bran Finishing Machine

Wheat Bran Finishing Machine

-

Air Flow Dryer

Air Flow Dryer

-

ZLSP-B R-Type Pellet Press Machine

ZLSP-B R-Type Pellet Press Machine

-

Oil Neutralization/Deacidification Process

Oil Neutralization/Deacidification Process