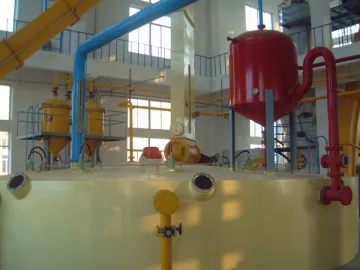

Oil Bleaching Process

The oil bleaching process aims to remove pigment and other impurities from crude oil in order to decolor and purify the oil.

Working Principle

The feed oil may go through a series of treatment includes acid conditioning, degumming, neutralizing or washing. It enters into the bleaching equipment through the bleaching heater in which the oil is heated to bleaching temperature and expelled into the slurry mixing machine.

The amount of bleaching earth is determined by a valve dosing system. The bleaching earth is introduced following the oil spray carried out in the mixing chamber for better mixing effects. In such a case, it is unable to enter the bleaching vacuum system. The bleaching earth has the ability to absorb residual gum, soap, trace metal, colored body as well as other polar impurities.

The equipment adopted for oil bleaching process is designed with numerous agitated compartments and runs under vacuum so as to guarantee complete elimination of moisture and air. The mixture of dried oil and bleaching earth is expelled by the bleacher discharge pump to one of the filters in which the used bleaching earth is excluded.

The filtered oil is collected in the filtrate receiver. The bleached oil pump sends the oil to deodorizing device through one of the alternating polishing filters.

Filter Management

The standard bleaching system works based on the employment of two filters. One works online while the other being cleaned and prepared for the following cycle. If reaching its maximum capacity, as presented by the high feed pressure, a filter will be off-line for cleaning and the other filter will be put into use.

Relevant Equipment

1. ZDL Type Vibrating Slagging Filter Machine

This equipment comes with a uniquely designed filter plate, thus needing no filter cloth or paper. In this way, the production costs can be significantly reduced. The fully sealed filtering room guarantees no environment contamination and oil material loss. This machine filters slag by vibration, asking for less labor and power. It can also achieve automatic and continuous operation.

Filter Principle

1. This filter machine works with the metal mesh, filter additive and pressure.

2. The metal mesh consists of a multi-layered mesh and framework.

3. The bleaching additive will generate a conductive layer on the mesh for filtration.

4. This filtering equipment is used for bleaching salad oil and crude oil.

2. Plate Filter Press

The plate filter press is characterized by the simple structure, easy operation and maintenance, high purification, as well as stable and great production capacity. It is mostly used to process crude oil, refined oil or bleaching earth containing oil.

Technical Specifications

| Filter Area | 1-800 m2 |

| Work Pressure | 0.5~3MPa |

| Capacity | 1~300 T/D |

KMEC is a China-based oil bleaching equipment manufacturer and supplier. In addition to oil refining equipment, we also offer wheat washing machine, pellet press machine, rotary drum dryer, LIPP silo storage system, and more.

Related Names

Slagging Filter | Oil Decolorization

Links:https://www.globefindpro.com/products/82877.html

-

Flat Die Pellet Mill (R-Type)

Flat Die Pellet Mill (R-Type)

-

ZLSP-Q D-Type Gasoline Pellet Mill

ZLSP-Q D-Type Gasoline Pellet Mill

-

Cleaning Sieve, Destoner, Crusher

Cleaning Sieve, Destoner, Crusher

-

Beans Dehuller

Beans Dehuller

-

Oil Bottling/Oil Filling Machine

Oil Bottling/Oil Filling Machine

-

Electric Sieve Stretching Machine

Electric Sieve Stretching Machine

-

Oil Seed Extruder/Extruding Machine

Oil Seed Extruder/Extruding Machine

-

Drum Chipper

Drum Chipper

-

Solvent Extractor

Solvent Extractor

-

Wheat Bran Finishing Machine

Wheat Bran Finishing Machine

-

Air Flow Dryer

Air Flow Dryer

-

ZLSP-B R-Type Pellet Press Machine

ZLSP-B R-Type Pellet Press Machine