Magnetic Separation Machine

The TCXT magnetic separation machine is employed to separate metal magnetic materials from grains. It has been at present applied in vegetable oil plant, flour mill, feed factory, brewery, etc.

Technical Specifications

| Model | Capacity (t/h) | Inlet Diameter (mm) | Weight (kg) | Magnetic Field Intensity (GS) | Height (mm) |

| TCXT15 | 10-15 | Φ150 | 55 | ≥ 3000 | 600 |

| TCXT20 | 20-30 | Φ200 | 80 | 600 | |

| TCXT25 | 35-50 | Φ250 | 120 | 600 | |

| TCXT30 | 45-70 | Φ300 | 170 | 720 | |

| TCXT40 | 65-75 | Φ400 | 225 | 720 |

Working Principle

The main body of this product is manufactured from ferromagnetic material and magnetic field is generated inside. After the raw materials and magnetic impurities contained passing through the inlet, a uniform circular material layer is formed around permanent magnet. As magnetized by the magnetic field, the magnetic metal impurities are absorbed onto the pole plate of the permanent magnet. The raw materials pass through the area with magnetic field and get out of the magnetic separation machine through the bottom port. In this way, the separation is carried out.

As a professional air aspirator and air suction channel manufacturer and supplier in China, we also provide assembly silo storage system, 10-250T flour mill plant, solvent recovery equipment, electric pellet mill, among others.

Related Names

Magnetic Separator | Magnetic Separation Equipment

Links:https://www.globefindpro.com/products/82892.html

-

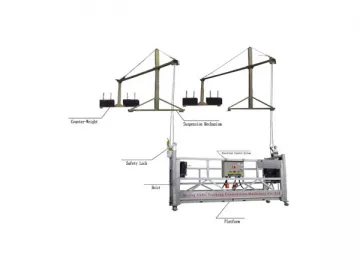

Industrial Maintenance Suspended Platform

Industrial Maintenance Suspended Platform

-

Laboratory Roller Mill

Laboratory Roller Mill

-

3-4 Ton Tower Crane

3-4 Ton Tower Crane

-

Wheat Scourers and Wheat Brushing Machine

Wheat Scourers and Wheat Brushing Machine

-

Aluminum Alloy Suspended Access Platform

Aluminum Alloy Suspended Access Platform

-

Low and High Pressure Fan

Low and High Pressure Fan

-

SC100 Construction Hoist

SC100 Construction Hoist

-

10-250T Flour Mill Plant

10-250T Flour Mill Plant

-

SMZ150 Self-propelled Gantry Hoist

SMZ150 Self-propelled Gantry Hoist

-

SS100/100 Material Hoist

SS100/100 Material Hoist

-

Custom Shape Suspended Platform

Custom Shape Suspended Platform

-

Plansifter

Plansifter