Pneumatic Flour Mill

1. FMF Series

The FMF pneumatic flour mill is a main machine in wheat processing line. It uses the pneumatic system to control rollers. The upper part is manufactured from steel material while the base bottom parts are made of cast iron. With a modular design, the feeding system can be taken out completely for easy maintenance. It can be driven separately for remote roller adjustment. Additionally, the roller is very sensitive to adjustment. The below parts can be customized with the pneumatic controlling set, electrical controlling set, and four roller milling unit or eight roller milling machine with the roller diameter being 250mm, 300mm, etc.

Technical Specifications

| Model | Specification of Grinding Roller (diameter × length)(mm) | Distance Between Milling and Feeding Roller (mm) | Speed Ratio of Feeding and Milling Rollers | Rotation Speed of Feeding and Rolling Rollers(RPM) | Rotation Speed of Front Feeding Roller (RPM) | Type of Feeding Roller | Working Pressure of Air Cylinder (MPa) | Max. Motor Power for Each Pair of Grinding Roller (kW) | |

| 1 | FMFQ10×2A | 250×1000 | 250 | 1.25: 1~ 2.5: 1 | 450 ~ 550 | 60 ~ 260 | Double Rollers | 0.6 ~ 0.7 | 22 |

| 2 | FMFQJ10×2 | 250×1000 | 250 | 450 ~ 550 | 0.6 ~ 0.7 | 22 | |||

| 3 | FMFD10×2 | 250×1000 | 250 | 450 ~ 550 | 22 | ||||

| 4 | FMFQ(3)10×2 | 300×1000 | 300 | 400 ~ 500 | 0.6 ~ 0.7 | 30 | |||

| 5 | FMFQJ(3)10×2 | 300×1000 | 300 | 400 ~ 500 | 0.6 ~ 0.7 | 30 | |||

| 6 | FMFD(3)10×2 | 300×1000 | 300 | 400 ~ 500 | 30 | ||||

| 7 | FMFQ10×4 | 250×1000 | 250 | 450 ~ 550 | 0.6 ~ 0.7 | 22 | |||

| 8 | FMFQ8×2 | 250×800 | 250 | 450 ~ 550 | 0.6 ~ 0.7 | 22 | |||

| 9 | FMFQJ8×2 | 250×800 | 250 | 450 ~ 550 | 0.6 ~ 0.7 | 22 | |||

| 10 | FMFQJ6×2 | 250×600 | 250 | 450 ~ 550 | 0.6 ~ 0.7 | 22 | |||

| 11 | FMFQ12.5×2 | 300×1250 | 300 | 400 ~ 500 | 0.6 ~ 0.7 | 30 | |||

| 12 | FMFD12.5×2 | 300×1250 | 300 | 400 ~ 500 | 30 | ||||

| 13 | FMFQJ12.5×2 | 300×1250 | 300 | 400 ~ 500 | 0.6 ~ 0.7 | 30 | |||

| 14 | FMFQ12.5×4 | 300×1250 | 300 | 400 ~ 500 | 0.6 ~ 0.7 | 30 | |||

2. FMFG Series

The FMFG series flour mill is made, adopting the latest technology, with a novelty structure and excellent performances. It is applicable to produce wheat flour and starch, grind grains and crush other materials. The grinding roller has high rotation accuracy, precise rolling distance adjustment, accurate feeding as well as flexible feeding methods. This flour making device has low noise level while being vibration free and environmental friendly. It is excellent for medium and small sized flour plants.

Technical Specifications

| Model | Diameter Range of Grinding Roller (mm) | Diameter of Feeding Roller (mm) | Power (kW) | Weight (kg) | Overall Dimension (L×W×H) (mm) |

| FMFG4×2 | Φ250-Φ 220 | 2× Φ74 | 4-11 | 1310 | 1200×1490×1700 |

| FMFG5×2 | Φ250-Φ 220 | 2× Φ74 | 4-15 | 1680 | 1300×1490×1700 |

| FMFG6×2 | Φ250-Φ 220 | 2× Φ74 | 4-18.5 | 2000 | 1400×1490×1700 |

3. 6F Series

The flour mill is a one-side inclined small scale machine. Its grinding roller uses the rolling bearing, thus generating small friction. This product consumes little power while has high efficiency. Due to the compact and reasonable construction, it is simple and convenient to operate. This flour making equipment can be used separately or connected with other equipment to form a flour processing unit. It is mainly adopted for wheat processing but also suitable for maize, buck wheat, broomcorn, etc.

Technical Specifications

| Item | Specifications | |||||

| 2235 | 2240 | 2250 | 2540 | 2550 | 2560 | |

| Diameter of Grinding Roller (mm) | 220 | 220 | 220 | 250 | 250 | 250 |

| Length of Grinding Roller (mm) | 350 | 400 | 500 | 400 | 500 | 600 |

| Power(kW) | 3-11 | 4-15 | 4-15 | 5.5-15 | 5.5-18.5 | 5.5-18.5 |

| Speed Ratio of Fast and Slow Rollers | 2.5:1 2:1 | 2.5:1 2:1 | 2.5:1 2:1 | 2.5:1 1.25:1 | 2.5:1 1.25:1 | 2.5:1 1.25:1 |

| Weight (kg) | 480 | 500 | 540 | 850 | 870 | 1000 |

| Overall Dimension (mm) (L×W×H) | 900×600×620 | 950×600×620 | 1000×600×680 | 1100×640×680 | 1200×640×680 | 1300×640×680 |

4. FSFZ Series Flake Disrupter

This product can function as the auxiliary equipment for the flour mill. It is used to impact materials processed by the reduction and scratch systems so as to loosen particles and to separate endosperm from the husk. The application of flake disrupting machine can effectively improve flour extraction rate. The simple and compact design makes this whole product convenient to install with small floor space.

Technical Specifications

| Model/ Item | Output (t/h) | Diameter of Rotor Disc (mm) | Rotation Speed of Rotor Disc (RPM) | Power (Kw) | Overall Dimension (mm) (L× W× H) |

| 43 | 1-2 | Φ430 | 2960 | 3 | 670×550×570 |

| 1.5-2.3 | 4 | ||||

| 51 | 2-2.3 | Φ510 | 2960 | 5.5 | 770×660×635 |

5. FFC Series Grinder

This product has a fluted disc structure. Taking advantage of the high speed movement of moving and fixed plates, it grinds materials into powder with the impact and friction of fluted disc to materials as well as the impact among materials.

This grinder has a simple and solid structure, steady running, as well as good grinding effect. The grinded materials can be directly expelled from milling chamber of the main machine. The particles in different sizes can be achieved by using the sieve plates with different mesh. This product can be used in chemical plant, food product factory, feed plant, etc.

Technical Specifications

| No | Model | Power (kW) | Output (kg/h) | Weight (kg) |

| 1 | M6FFC-800 | 55/380V,50Hz | 2000-8000 | 1200 |

| 1 | M6FFC-500 | 22/380V,50Hz | 1000-3000 | 460 |

| 1 | M6FFC-360 | 11/380V,50Hz | 400-1800 | 168 |

| 3 | M6FFC-270 | 7.5/380V,50Hz | 250-800 | 98 |

| 4 | M6FFC-230 | 2.2/220V,50Hz | 150-560 | 68 |

| 5 | M6FFC-160 | 1.5/220V,50Hz | 50-200 | 38 |

As a China-based pneumatic flour mill manufacturer and supplier, KMEC provides a broad range of products, including oil deodorization system, air flow dryer, oil press machine, electric pellet press machine, and much more.

Related Names

Flour Milling Machine | Pneumatic Roller Mill

Links:https://www.globefindpro.com/products/82906.html

-

Small Oil Refinery

Small Oil Refinery

-

Maize Milling Machine Plant

Maize Milling Machine Plant

-

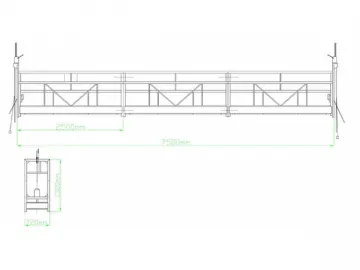

U Shape Suspended Access Platform

U Shape Suspended Access Platform

-

8-10 Ton Tower Crane

8-10 Ton Tower Crane

-

Conveying Equipment

Conveying Equipment

-

SC200 Construction Hoist

SC200 Construction Hoist

-

SC100/100 Construction Hoist

SC100/100 Construction Hoist

-

Variable Frequency Construction Hoist

Variable Frequency Construction Hoist

-

Steel Suspended Access Platform

Steel Suspended Access Platform

-

Flour Purifier

Flour Purifier

-

Sesame Cleaning Equipment

Sesame Cleaning Equipment

-

Luffing Jib Crane

Luffing Jib Crane