Four-Roll Plate Bending Machine

The JW12 series four-roll plate bending machine is designed and manufactured based on German and Italian technologies. For enhanced reliability, its electrical parts, hydraulic system and other key components are all supplied by famous domestic or world-class manufacturers. This plate rolling machine is fully hydraulic driven, and supports digital control. It offers 50%-60% higher efficiency than three-roller plate bending machines.

To suit the processing demand of sheet metals with varied thickness and width, the hydraulic plate bending machine is designed to support clamping force adjustment. The clamping force can be convenient adjusted via the pressure regulating valve in the hydraulic station.

Italian Technology

1. This four-roll plate bending machine features a new but efficient system which contains zero friction swing guide, zero friction auto-collimation bearing, multi-channel hydraulic power system as well as hydraulic planetary drive that is directly coupled on compression roll. The application of these advanced technologies significantly reduces energy loss, so, more energy is applied for sheet metal bending. This efficient system design makes sure our range of roll bending machine meets international standards.

2. Thanks to the planetary swing system, the load is limited within the machine frame. This is one of the reasons why our range of hydraulic plate bending machine delivers minimized structural deformation. The rolls are characterized by good stability, high rigidity, fluent swing and low friction, offering absolute precision.

3. The side roll pushes metal sheet to top roll with pretty long arc segment, so the sheet encloses top roll tightly, cutting down the springback of sheet metal. This makes our sheet metal bending roll ideal for making smaller-diameter cylinders and cones.

4. The four-roll plate bending machine adopts the permanent lubrication technology. Thus, lubrication oil is not required within the service life of bearing.

5. The planetary swing guide technology is applied for side rolls. The side roll is pinned on a solid central pin, and it carries out circular motion around the central hinged joint, completely eliminating linear friction. During plate rolling process, load is totally within the frame. Thus, this range of metal forming equipment features a compact machine frame with high strength and rigidity.

6. With a special roller system design, this plate bending machine is able to create large forming force and pre-bending force, thus reducing the length of flat ends.

7. Regardless of the diameter of workpiece, the bending power increase is achieved even at prebending stage. During the swing movement of side roll, a beneficial and constant positive leverage is maintained. Owing to the effect of leverage, the geometric movement multiplies the power of hydraulic cylinder, and the bending power is concentrated on the prebending area, further cut down the length of flat end.

Applicable User

This plate bending machine is easy for operation, so it fits for inexperienced users. Also, it is suitable for conditions where high precision, improved quality and high production rate are needed. It is great for enterprises dedicated for reducing labor cost and labor intensity, as it requires only one operator.

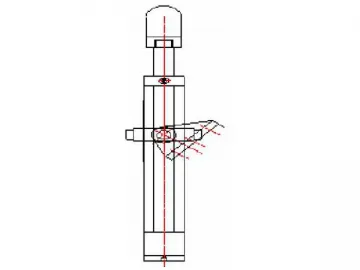

Product Structure

1. Major Components

The major components for this plate bending machine contain top roll, lower roll, side rolls, base plate, ejection device, main transmission device as well as left and right racks.

The top roll is the drive roll which can rotate in both positive and negative directions, and the power is supplied by hydraulic motor. The lower roll and side rolls are driven rolls. The side roll is designed to move up and down in arc trace along the frame guide, and this motion is achieved depending on the friction between metal plate and rolls. All the actions of rolls are realized with the help of hydraulic cylinder, and these actions are used to clamp metal plate tightly to receive bending treatment. In addition, asymmetrical bending is also available.

The machine frame is made of steel plate through welding process, after which annealing treatment is applied to relieve stress. The movement of two side rolls is limited within the fixed ejection device, while the lower roll is in the middle of the roll bender. On the other hand, the hydraulic transmission device is coupled with working roll directly, and the entire hydraulic power station is set at the middle or end of the base. All the operations are carried out on the control panel that is installed at the side of our four-roll plate bending machine.

The top roll is mounted at a fixed position, and it is pressed by a balancing device at the end of our plate rolling machine, while the oil cylinder is responsible for the tipover and reset actions of ejection device.

2. Hydraulic System

The hydraulic system mainly consists of the hydraulic pump, valve group and the auxiliary piping. The hydraulic valve we applied is superposition valve supplied by Yuci Yuken Hydraulics, and pipeline is simple with less leakage, allowing convenient maintenance. Meanwhile, there are monitoring points at all the inlet and outlet of the hydraulic system which facilitate both maintenance and trouble shooting procedure. The hydraulic station is placed on the machine base, cutting down required space, and simplifying the foundation.

The hydraulic system of our four-roll plate bending machine is state-of-the-art, and some details are listed below.

a. It has three loops which are synchronizing loop, speed loop, as well as overpressure protection and pressure regulating loop. The pressure regulating loop adjusts working pressure of the system through main overflow valve, and the working pressure is 19.5MPa.

b. The raise and descent of lower roll and side rolls are protected with pressure limit protection by overflow valves.

c. This system is fabricated strictly according to the GB3766-2001 standard. The bending radius is reasonably designed, and it is not less than 90°, while the pipe clamps are scientifically arranged to avoid shock and vibration.

d. High efficiency and energy conservation are taken into consideration when designing our hydraulic system, reducing power loss and heat source.

e. Troubleshooting solutions for the hydraulic system are available.

Electronic Control System

This four-roll plate bending machine is equipped with a PLC system, and thus it offers advantages such as high degree of automation, excellent machining precision, low failure rate as well as remarkable working efficiency.

1. General view

The electronic control system is comprised of the control panel, operation panel and the handheld button box. The power supply is 3 phase 4 wire type with 380V/50Hz. With the help of PLC, this range of sheet metal processing equipment gets rid of numerous relays, cutting down the number of relay. Thus, the action is reliable, and the service life is very long.

All control buttons and indicator lights are set on the control panel, allowing operators to perform instant and direct monitoring of the working status.

2. Protection measures

(1) The electric motor is available with a circuit breaker for short circuit protection, as well as a thermal replay for load protection.

(2) Upper and lower limit switches are also applied to guarantee the normal working of ejection device.

(3) The circuit breaker for the main power supply circuit comes with a shunt release. An emergency stop button is provided to cut off power supply under emergency conditions.

3. Failure indication

When the PLC breaks down, the failure indicator will be lighted up to send alarm message.

Working Principle

The working principle of our plate bending machine is shown in the following diagrams.

Links:https://www.globefindpro.com/products/82914.html

-

5-6 Ton Tower Crane

5-6 Ton Tower Crane

-

Small and Medium-Sized 3 Roll Plate Bending Machine

Small and Medium-Sized 3 Roll Plate Bending Machine

-

3-Roll Plate Bending Machine for Ship

3-Roll Plate Bending Machine for Ship

-

3 Roller Plate Bending Machine for Trailer

3 Roller Plate Bending Machine for Trailer

-

Hex Bolt

Hex Bolt

-

Adjustable 3-Roll Plate Bending Machine

Adjustable 3-Roll Plate Bending Machine

-

Flat Top Tower Crane

Flat Top Tower Crane

-

SC200 Construction Hoist

SC200 Construction Hoist

-

Conveying Equipment

Conveying Equipment

-

8-10 Ton Tower Crane

8-10 Ton Tower Crane

-

U Shape Suspended Access Platform

U Shape Suspended Access Platform

-

Maize Milling Machine Plant

Maize Milling Machine Plant