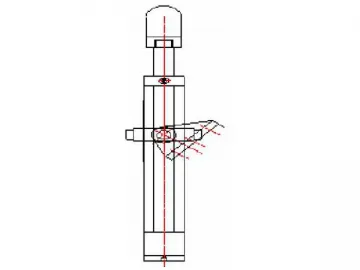

5-6 Ton Tower Crane

The 5-6 ton tower crane has the merits of creative design and reliable operation. It is equipped with a horizontal arm bracket, a hydraulic self-propelling mechanism, and an arm-trolley radius-changing mechanism. Widely applied in various construction sites, this hoisting equipment shows excellent speed-control capacity and operational stability as well as high work efficiency.

Specifications of 5-6 Ton Tower Crane| Model | QTP100 (TC5515) (Flat-Top) | QTP80 (TC5511) (Flat-Top) | QTZ63F (TC5613) (TC5810) | QTZ63B (TC5610) (TC5013) | QTZ63C (TC5211) | QTZ63C (TC5013) | QTZ50A (TC4808) | QTZ50 (TC5010) |

| Max working radius (m) | 55 | 55 | 58 | 56/50 | 52 | 50 | 48 | 50 |

| Free height (m) | 43.5 | 41 | 41 | 41 | 40 | 40 | 34 | 34 |

| Max load (t) | 6 | 6 | 6 | 6 | 6 | 6 | 5 | 5 |

| Tip load (t) | 1.5 | 1.1 | 1 | 1.0/1.3 | 1.1 | 1.3 | 0.8 | 1 |

| Max height (m) | 161 | 161 | 161 | 161 | 140 | 140 | 140 | 139 |

| Wall ties for Max. height (sets) | 6 | 8 | 7 | 6 | 6 | 6 | 6 | 7 |

| Main material specs (mm) | Square Steel Tube 1352×12 | Square Steel Tube 1352 ×12 | Square Steel Tube 1352 ×12 | Square Steel Tube 1352 ×10 | 160×14 Angle Steel (Standard Section) 160×16 Angle Steel (Reinforcing Section) | 160×14 Angle Steel (Standard Section) 160×16 Angle Steel (Reinforcing Section) | Angle Steel 160×12 | Angle Steel 160×12 |

| Mast section dimensions (m) | 1.835×1.835×2.5 | 1.835×1.835×2.5 | 1.835×1.835×2.5 | 1.835×1.835×2.5 | 1.615×1.615×2.5 | 1.615×1.615×2.5 | 1.5×1.5×2.5 | 1.5×1.5×2.5 |

| Hoisting speed (m/min) | 100/50/8.5 | 80/40/10 | 80/40/10 | 80/40/10 | 80/40/10 | 80/40/10 | 70/35/9 | 70/35/9 |

| Min. steady falling speed (m/min) | 4.25 | 5 | 5 | 5 | 5 | 5 | 4.5 | 4.5 |

| Slewing speed (r/min) | 0-0.65 | 0-0.62 | 0-0.62 | 0-0.62 | 0-0.62 | 0-0.62 | 0-0.7 | 0-0.7 |

| Radius-changing speed (m/min) | 0-60 | 40/20 | 40/20 | 40/20 | 40/20 | 40/20 | 40/20 | 40/20 |

| Jacking speed (m/min) | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.5 | 0.5 |

| Total motor power (kW) | 67 | 60 | 55.2 | 55.2 | 32.8 | 32.8 | 21.1 | 21.1 |

| Independent structure weight (kg) | 53694 | 37800 | 37800 | 36800 | 33279 | 33052 | 25522 | 25522 |

| Counter weight (T) | 17.64 | 16.2 | 16.2 | 14.85 | 11.475 | 11.475 | 8.12 | 8.12 |

| Containers for shipment (free height) | 8 ×40'HQ | 6 × 40'HQ | 6 ×40'HQ | 6 × 40'HQ | 4×40'HQ 1×20'GP | 4×40'HQ 1×20'GP | 4×40'HQ | 4×40'HQ |

Advantages

As a combination of the latest technologies, the tower crane is equipped with a variable frequency slewing device and a wide variety of reliable safety devices, such as the hoisting height limiter, slewing range limiter, and multifunctional limiter offering great help to control the load moment, hoisting capacity and trolley moving range. In addition, there are also electric safety devices, like anemoscopes and obstacle lights, and mechanical safety devices to prevent the breaking of trolley axles and wire ropes.

The electric control system of our tower crane adopts the advanced PLC (Programmable Logic Controller) with frequency converter that realizes variable speed regulation and enhances the reliability, maneuverability and stability of the control system. Also, the work efficiency of tower crane is improved. The PLC unit can diagnose the cause of breakdowns.

Our hydraulic crane is equipped with electrical components introduced from world-renowned suppliers like OMRON, YASKAWA, Schneider (TE) and MEAN WELL to decrease the failure rate of the electric control system and increase the working efficiency.

Show Details

Links:https://www.globefindpro.com/products/82915.html

-

Small and Medium-Sized 3 Roll Plate Bending Machine

Small and Medium-Sized 3 Roll Plate Bending Machine

-

3-Roll Plate Bending Machine for Ship

3-Roll Plate Bending Machine for Ship

-

3 Roller Plate Bending Machine for Trailer

3 Roller Plate Bending Machine for Trailer

-

Hex Bolt

Hex Bolt

-

Adjustable 3-Roll Plate Bending Machine

Adjustable 3-Roll Plate Bending Machine

-

Hydraulic Press Brake

Hydraulic Press Brake

-

Four-Roll Plate Bending Machine

Four-Roll Plate Bending Machine

-

Flat Top Tower Crane

Flat Top Tower Crane

-

SC200 Construction Hoist

SC200 Construction Hoist

-

Conveying Equipment

Conveying Equipment

-

8-10 Ton Tower Crane

8-10 Ton Tower Crane

-

U Shape Suspended Access Platform

U Shape Suspended Access Platform