Adjustable 3-Roll Plate Bending Machine

The adjustable 3-roll plate bending machine is designed for roll bending of sheet metals in industries such as boiler, shipbuilding, aviation, decoration, power generation, metal construction, etc. With enhanced reliability and performance, the plate rolling machine is great for pre-bending and roll-forming of large-sized cylinder or conical shapes.

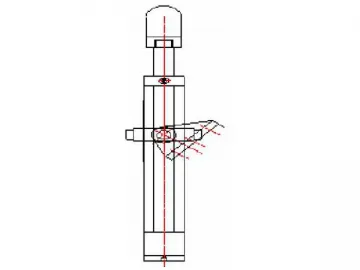

The upper roll of the metal bending machine supports vertical movements while the lower roll supports horizontal movements. Through moving the shaft seat of lower roll, the upper and lower rolls will be unsymmetrical, thus allowing the machine to realize pre-bending process. When the two rollers are driven by the universal joint and hydraulic motor/reducer to rotate, the 3 roll plate bending machine is allowed for rolling process.

Main ComponentsThis sheet metal bending roll is mainly composed of the top roll assembly, lower roll assembly, support roll assembly, main transmission, ejection device, left and right rack, base, hydraulic system, and the electrical control system.

1. Top Roll Assembly

The assembly is made up of the oil cylinder, bearing seat, top roll and the double row self-aligning bearing. Two oil cylinders offer the pressure required for bending metal plate, and the working pressure for main cylinder is 19.5Mpa. The top roll is made of 42CrMo, and offers hardness and surface hardening of HB260-300 and HRC48-52, respectively.

2. Lower Roll Assembly

This part mainly consists of the lower roll, bearing seat, sliding bearing, telescopic cylinder or gear, etc. The 3-roll plate bending machine is equipped with a speed reducer to provide power, thus realizing the rotation of lower roll, and the power for horizontal movement is supplied by oil cylinder. The hardness and surface hardening for lower roll are HB260-280 and HRC48-52.

3. Support Roll Assembly

The assembly is comprised of support roll, worm and gear, wedge block and others. Our range of roll bending machine comes with four support rolls which can be adjusted vertically to suit varied loads of feeding material.

4. Main Transmission

The main transmission system supports rotation in both positive and negative directions, and serves to generate power for plate bending. It is made up of the motor, brake, hydraulic motor or reducer.

5. Ejection Device

The ejection device is used to take out finished product, and it is composed of the ram, oil cylinder and the rack.

6. Fixed, Tip-Over Racks and Base

These components are steel welded, and then annealed to relieve stress.

7. Hydraulic System

Our adjustable 3 roll plate bending machine is equipped with an advanced hydraulic system which consists of the gear pump, valve group, auxiliary pipeline and others. The hydraulic valve is superposition valve supplied by ASHUN Fluid Power Co., and the simple pipeline allows convenient maintenance. This system has three loops: pressure regulating loop, synchronous loop, and speed loop.

The pressure regulating loop is designed to adjust the working pressure of this system with the help of main overflow valve, and the working pressure is 19.5MPa.

The synchronous loop takes advantage of flow divider valve and throttle valve to realize the preliminary synchronization for raise and descent of top roll, and horizontal movement of lower roll. Meanwhile, the plate bending machine adopts a displacement sensor for detection, and the positioning accuracy is ±0.15mm.

The speed loop controls the tip over and reset actions of ejection device, and the throttle valve is used to adjust this loop.

8. Electrical Control System

The system contains electrical cabinet, operating console, and handheld button box. The power supply is 380V/50Hz, and the main switch has overload protection as well as short circuit protection.

The adjustable 3-roll plate bending machine features fewer relays due to the application of PLC, so, the action is reliable and the service life is prolonged. On the operating console are buttons and indicators for the whole working process, and they are responsible for the control of working operation and status. Additionally, limit switches are set at the ends of all moving parts, and emergency stop buttons are also applied. Thus, both the operator and the metal fabrication equipment are well protected.

Standards

This 3-roll plate bending machine is scientifically designed and manufactured, satisfying relevant standards as below.

| 1. JB/T 8796-1998 2. JB/T 2249-2001 3. JB/T 3185.1-1999 4. JB/T 8797-1998 5. JB/T 1829-1997 6. GB 17120-1997 | 7. JB/T 8609-1997 8. JB 3623-84 9. JB 9971-1999 10. GB 3766-83 11. GB 16754-200812. GB/T 5226.1-2008 |

Technical Parameters

| Model | Max. plate thickness | Max. plate width | Yielding limit of plate | Coiling speed | Min. bending diameter at full load | Top roll diameter | Lower roll diameter | Central distance between lower rolls | Main motor power |

| mm | mm | mm | m/min | mm | mm | mm | mm | kW | |

| W11X-12×2000 | 12 | 2000 | 245 | 6.46 | 500 | 240 | 200 | 310 | 11 |

| W11X-12×2500 | 12 | 2500 | 245 | 5 | 750 | 280 | 240 | 360 | 11 |

| W11X-12×3000 | 12 | 3000 | 245 | 5 | 650 | 280 | 240 | 360 | 11 |

| W11X-16×2000 | 16 | 2000 | 245 | 5 | 750 | 280 | 240 | 360 | 11 |

| W11X-16×2500 | 16 | 2500 | 245 | 5 | 750 | 280 | 240 | 360 | 11 |

| W11X-16×3200 | 16 | 3200 | 245 | 5 | 900 | 340 | 280 | 440 | 11 |

| W11X-20×2000 | 20 | 2000 | 245 | 5 | 750 | 280 | 240 | 440 | 11 |

| W11X-20×2500 | 20 | 2500 | 245 | 5 | 850 | 340 | 280 | 490 | 15 |

| W11X-25×2000 | 25 | 2000 | 245 | 5 | 850 | 340 | 280 | 490 | 22 |

| W11X-25×2500 | 25 | 2500 | 245 | 4.5 | 900 | 380 | 300 | 600 | 30 |

| W11X-30×2000 | 30 | 2000 | 245 | 4.5 | 900 | 380 | 300 | 600 | 30 |

| W11X-30×2500 | 30 | 2500 | 245 | 4.3 | 1100 | 460 | 380 | 600 | 37 |

| W11X-30×3000 | 30 | 3000 | 245 | 5 | 1200 | 480 | 400 | 600 | 37 |

| W11X-30×3200 | 30 | 3200 | 245 | 5 | 1200 | 500 | 400 | 600 | 37 |

| W11X-40×2000 | 40 | 2000 | 245 | 5 | 1200 | 480 | 400 | 600 | 37 |

| W11X-40×2500 | 40 | 2500 | 245 | 5 | 1400 | 500 | 400 | 600 | 37 |

| W11X-40×3000 | 40 | 3000 | 245 | 4.37 | 1600 | 500 | 400 | 650 | 45 |

| W11X-50×3000 | 50 | 3000 | 245 | 4 | 2000 | 600 | 480 | 700 | 60 |

| W11X-60×3000 | 60 | 3000 | 245 | 4 | 2000 | 700 | 560 | 800 | 75 |

Note: These parameters are subject to change without prior notice.

Major Outsourced Components

| Item | Description | ||

| Bearing | Type | Heavy duty double row self-aligning bearing | |

| Supplier | Wafangdian Bearing | ||

| Working roll | Material | 42CrMo | |

| Hardness | HB260-300 | ||

| Place of origin | Wuxi | ||

| Rack and side rack | Material | Q235A | |

| Processing method | Welding, annealing, CNC boring and milling machine | ||

| Supplier | Jiuwei Heavy Industry Machine | ||

| Reducer | Type | Cylinder gear speed reducer (main transmission) | |

| Supplier | Guomao Guotai Reducer | ||

| Main motor | Mpdel | YZR | |

| Supplier | Jiangyin Kaicheng Electromechanical | ||

| Hydraulic system | Hydraulic pump | Type | Plunger pump |

| Supplier | Hefei Hydraulics | ||

| Valve | Supplier | Yuci Yuken Hydraulics | |

| Main oil cylinder | Cylinder body and piston rod | 45 steel, HB217-255 | |

| Supplier | Nantong Jiujiu Hydraulic Machine | ||

| Seal for main oil cylinder | UN type | ||

| Supplier | Ding Zing | ||

| CNC system (economical type) | Main electrical parts | SIEMENS | |

| Programmable display | WEINVIEW | ||

| PLC | OMRON | ||

| Encoder | SIEMENS | ||

| CNC software | Jiuwei Heavy Industry Machine | ||

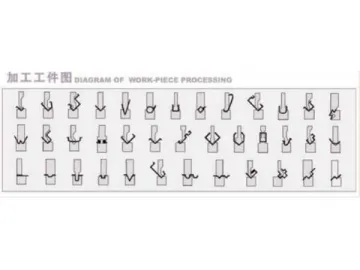

Working Principle

Links:https://www.globefindpro.com/products/82921.html

-

Hydraulic Press Brake

Hydraulic Press Brake

-

Hex Socket Head Cap Screw

Hex Socket Head Cap Screw

-

CNC Hydraulic Press Brake

CNC Hydraulic Press Brake

-

DIN 558

DIN 558

-

Hydraulic Tandem Press Brake

Hydraulic Tandem Press Brake

-

SS100 Material Hoist

SS100 Material Hoist

-

Hex Bolt

Hex Bolt

-

3 Roller Plate Bending Machine for Trailer

3 Roller Plate Bending Machine for Trailer

-

3-Roll Plate Bending Machine for Ship

3-Roll Plate Bending Machine for Ship

-

Small and Medium-Sized 3 Roll Plate Bending Machine

Small and Medium-Sized 3 Roll Plate Bending Machine

-

5-6 Ton Tower Crane

5-6 Ton Tower Crane

-

Four-Roll Plate Bending Machine

Four-Roll Plate Bending Machine