Precision Sheet Metal Shear

1. The QH11D series precision sheet metal shear features small shearing angle and inclined shearing direction, which minimizes the distortion of sheet metals.

2. A pneumatic support device is available as an option, thus allowing the plate shearing machine to cut long and thin sheets.

3. The workpiece-holding device with belleville spring offers big force to clamp the sheet, preventing the movement of workpiece during shearing process. Thus, the machining precision is guaranteed.

4. The metalworking shear is designed with a foot switch to control the brake motor.

5. The blade clearance is regulated rapidly by manual adjustment device, and the value is displayed. Hence, it is easy to obtain desired blade clearance.

6. Our metal plate shearer is equipped with a workpiece-holding mat made of PU, avoiding surface damage when shearing soft material or smooth sheet.

7. The precision sheet metal shear has a frame welded by steel plate. The structure is processed via vibratory stress relief to eliminate internal stress, thus avoiding structural distortion and ensuring long term stability.

Technical Parameters

| Model | Sheet thickness(mm) | Sheet width(mm) | Shear angle | Stroke number(min-1) | Backgauge range (mm) | Work table height(mm) | Main motor power (kW) | Net weight (kg) | Overall Dimensions (L×W×H, mm) |

| QH11D-3.5×1250 | 3.5 | 1250 | 1 ° 30' | 47 | 0-650 | 800 | 5.5 | 1450 | 1860×2210×1180 |

| QH11D-3.2×1500 | 3.2 | 1500 | 1 ° 30' | 47 | 0-650 | 800 | 5.5 | 1650 | 2124×2210×1180 |

| QH11D-3.2×2000 | 3.2 | 2000 | 1 ° 45' | 47 | 0-650 | 800 | 7.5 | 1800 | 2624×2210×1180 |

| QH11D-2.5×2500 | 2.5 | 2500 | 1 ° | 47 | 0-650 | 800 | 7.5 | 2080 | 3124×2210×1180 |

| QH11D-3.2×2500 | 3.2 | 2500 | 1 ° 18' | 47 | 0-650 | 800 | 7.5 | 2200 | 3124×2210×1180 |

| QH11D-3.2×3050 | 3.2 | 3050 | 1 ° 30' | 47 | 0-650 | 800 | 11 | 3950 | 3630×2250×1400 |

Links:https://www.globefindpro.com/products/82936.html

-

Sheet Metal Cut to Length Line

Sheet Metal Cut to Length Line

-

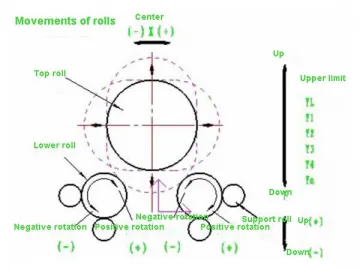

Mechanical 3-Roll Symmetrical Plate Bending Machine

Mechanical 3-Roll Symmetrical Plate Bending Machine

-

Carriage Bolt

Carriage Bolt

-

3506_1E

3506_1E

-

DIN 85-90

DIN 85-90

-

Electric Control Box

Electric Control Box

-

Single Action Hydraulic Press

Single Action Hydraulic Press

-

Suspended Platform Safety Lock

Suspended Platform Safety Lock

-

Three-Roll Hydraulic Plate Bending Machine

Three-Roll Hydraulic Plate Bending Machine

-

Suspended Platform Hoist

Suspended Platform Hoist

-

Manual Sheet Metal Folding Machine

Manual Sheet Metal Folding Machine

-

Hydraulic Swing Beam Shear

Hydraulic Swing Beam Shear