Mechanical 3-Roll Symmetrical Plate Bending Machine

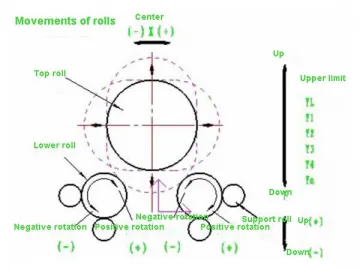

This range of mechanical 3-roll symmetrical plate bending machine has a simple but compact structure, allowing convenient operation and maintenance. Adopting mechanical drive, the plate rolling machine includes one top roll and two lower rolls. The top roll moves up and down in the direction that is perpendicular to the center of two lower rolls, and this is achieved with the help of worm and worm gear. The gear meshing between main motor, speed reducer and lower rolls is used to generate positive and negative rotations, providing torque to bend metal plate.

This mechanical roll bending machine is equipped with an electrical cabinet which has indicators for different actions, such as the upward and downward movements of top roll, positive and negative direction rotations for the lower roll, etc. In addition, this 3-roll plate bending machine only requires one operator, and the failure rate is very low.

Technical Parameters of W11 Series Roll Benders

| Model | Max. plate thickness | Max. plate width | Yielding limit of plate | Coiling speed | Min. bending diameter at full load | Top roll diameter | Lower roll diameter | Central distance between lower rolls | Main motor power |

| mm | mm | mm | m/min | mm | mm | mm | mm | kW | |

| W11-6×1500 | 6 | 1500 | 245 | 5 | 380 | 160 | 140 | 220 | 4 |

| W11-6×2000 | 6 | 2000 | 245 | 4.5 | 380 | 170 | 160 | 260 | 5.5 |

| W11-6×3200 | 6 | 3200 | 245 | 4.5 | 380 | 220 | 180 | 280 | 7.5 |

| W11-8×2000 | 8 | 2000 | 245 | 4.5 | 400 | 185 | 170 | 260 | 5.5 |

| W11-8×2500 | 8 | 2500 | 245 | 4.5 | 550 | 240 | 180 | 280 | 7.5 |

| W11-12×2000 | 12 | 2000 | 245 | 4.5 | 550 | 240 | 180 | 280 | 7.5 |

| W11-12×2500 | 12 | 2500 | 245 | 4.5 | 600 | 260 | 220 | 320 | 11 |

| W11-12×3000 | 12 | 3000 | 245 | 4 | 700 | 280 | 240 | 360 | 11 |

| W11-16×2000 | 16 | 2000 | 245 | 4 | 600 | 260 | 220 | 320 | 11 |

| W11-16×2500 | 16 | 2500 | 245 | 4 | 700 | 280 | 240 | 360 | 15 |

| W11-16×3200 | 16 | 3200 | 245 | 4 | 850 | 340 | 260 | 430 | 18.5 |

| W11-20×2000 | 20 | 2000 | 245 | 4 | 700 | 280 | 240 | 360 | 15 |

| W11-20×2500 | 20 | 2500 | 245 | 4 | 850 | 340 | 260 | 430 | 18.5 |

| W11-25×2000 | 25 | 2000 | 245 | 4 | 850 | 330 | 270 | 430 | 18.5 |

| W11-25×2500 | 25 | 2500 | 245 | 4 | 900 | 370 | 270 | 480 | 22 |

| W11-30×2500 | 30 | 2500 | 245 | 4 | 1200 | 420 | 360 | 550 | 30 |

| W11-30×3000 | 30 | 3000 | 245 | 4 | 1200 | 450 | 390 | 600 | 37 |

| W11-40×2500 | 40 | 2500 | 245 | 4 | 1250 | 500 | 400 | 600 | 37 |

| W11-50×2500 | 50 | 2500 | 245 | 4 | 1250 | 540 | 440 | 630 | 37 |

Note: These parameters are subject to change without prior notice.

Links:https://www.globefindpro.com/products/82938.html