CNC Hydraulic Swing Beam Shear

1. As indicated by its name, the QC12K series CNC hydraulic swing beam shear takes advantage of hydraulic drive, and the tool post moves like a swing beam, offering excellent performance with high shearing precision.

2. Its welded steel structure ensures high reliability and stability, as vibratory stress relief technique is adopted to eliminate stress.

3. The blade clearance supports fast and synchronous adjustment, and the metal plate shearer is able to automatically adjust the blade clearance after the desired value is put in.

4. The hydraulic swing beam shear is outfitted with a lighting device to facilitate manual scribing as well as shearing, and the stroke control of tool post adopts stepless mode, improving working efficiency largely.

5. The hydraulic shearing machine is equipped with a backgauge which is supposed to travel swiftly and automatically, and the data are showed on the display.

Major Components

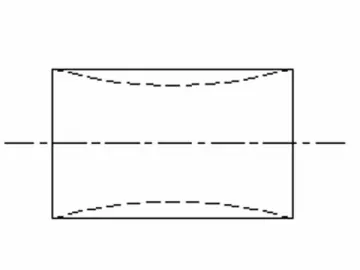

1. Machine Frame

The frame for the hydraulic shear is welded by steel plate, and good rigidity is obtained. Two cylinders are fixed on left and right columns, and there is an auxiliary knife holder on the work table which brings convenience for micro-adjustment of lower tool post. Meanwhile, the swing beam shear is available with a material feeding device on the work table to enhance operation convenience.

2. Workpiece-Holding Device

The workpiece-holding device mainly consists of several workpiece-holding cylinders that are installed on the bearing plate in the front of the CNC hydraulic swing beam shear. After oil flows into cylinder, the cylinder overcomes spring tension and clamp metal sheet tightly. When the shearing job is finished, it returns to the original place due to the spring tension.

3. Front Gauge and Backgauge

(1) Front gauge is set on the work table, and a scale is available to indicate values. The movable baffle plate is regulated to get desired value, and this is very convenient when shearing thin materials.

(2) The backgauge is fixed on the upper tool post, and it swings with upper tool post. It is motor-driven, and the power is transferred by the lead screw after the gearbox. In addition, manual micro-adjustment is also available.

4. Hydraulic System

The CNC hydraulic swing beam shear has a hydraulic system which is mainly made up of the control valve, oil pump, oil cylinder, return cylinder, workpiece-holding cylinder, combined oil way, etc. This system has many outstanding features, including reasonable structure, low noise, smooth running, high safety, and more.

5. Electrical System

The electrical system for the sheet metal shear is made up of the control cabinet, connection lines, control panel, main and assistant motors, foot switch and more. It ensures safe and reliable performance.

6. CNC System

The hydraulic swing beam shear employs an ESTUN CNC control system which delivers high precision, enhanced reliability, and accurate backguage control. Additionally, the CNC system offers the following features.

1. The 320×240 LCD display shows good resistance to oil, acid, scratch and radiation. The brightness is adjustable, and the IP rating of keyboard is IP65.

2. The USB port is available as a standard. Hence, the program and parameters are not only saved on the local computer, but can also be transferred to other computers with the help of a USB flash drive.

3. The software is simple, and data are typed in directly, realizing convenient operation.

Technical Parameters

| Model | Sheetthickness (mm) | Sheet width (mm) | Shear angle | Stroke number (min-1) | Backgauge range (mm) | Main motor power (kW) |

| QC12K-4×2500 | 4 | 2500 | 1°30' | 18 | 20-500 | 4 |

| QC12K-4×3200 | 4 | 3200 | 1°30' | 18 | 20-600 | 4 |

| QC12K-4×4000 | 4 | 4000 | 1°30' | 12 | 20-600 | 5.5 |

| QC12K-4×5000 | 4 | 5000 | 1°30' | 10 | 20-600 | 5.5 |

| QC12K-4×6000 | 4 | 6000 | 1°30' | 7 | 20-800 | 7.5 |

| QC12K-6×2500 | 6 | 2500 | 1°30' | 18 | 20-600 | 7.5 |

| QC12K-6×3200 | 6 | 3200 | 1°30' | 14 | 20-600 | 7.5 |

| QC12K-6×4000 | 6 | 4000 | 1°30' | 12 | 20-600 | 7.5 |

| QC12K-6×5000 | 6 | 5000 | 1°30' | 10 | 20-600 | 7.5 |

| QC12K-6×6000 | 6 | 6000 | 1°30' | 7 | 20-800 | 7.5 |

| QC12K-8×2500 | 8 | 2500 | 1°30' | 14 | 20-600 | 11 |

| QC12K-8×3200 | 8 | 3200 | 1°30' | 10 | 20-600 | 11 |

| QC12K-8×4000 | 8 | 4000 | 1°30' | 8 | 20-600 | 11 |

| QC12K-8×5000 | 8 | 5000 | 1°30' | 7 | 20-800 | 11 |

| QC12K-8×6000 | 8 | 6000 | 1°30' | 6 | 20-800 | 15 |

| QC12K-8×8000 | 8 | 8000 | 1°30' | 5 | 20-800 | 15 |

| QC12K-10×2000 | 10 | 2000 | 1°30' | 12 | 20-600 | 11 |

| QC12K-10×2500 | 10 | 2500 | 1°30' | 10 | 20-600 | 11 |

| QC12K-10×3200 | 10 | 3200 | 1°30' | 10 | 20-600 | 11 |

| QC12K-10×4000 | 10 | 4000 | 1°30' | 8 | 20-600 | 15 |

| QC12K-12×2000 | 12 | 2000 | 2° | 12 | 20-600 | 15 |

| QC12K-12×2500 | 12 | 2500 | 2° | 10 | 20-600 | 15 |

| QC12K-12×3200 | 12 | 3200 | 2° | 9 | 20-600 | 15 |

| QC12K-12×4000 | 12 | 4000 | 2° | 8 | 20-800 | 18.5 |

| QC12K-12×5000 | 12 | 5000 | 2° | 7 | 20-800 | 22 |

| QC12K-12×6000 | 12 | 6000 | 2° | 6 | 20-800 | 22 |

| QC12K-12×8000 | 12 | 8000 | 2° | 5 | 20-800 | 22 |

| QC12K-16×2500 | 16 | 2500 | 2° | 8 | 20-800 | 15 |

| QC12K-16×3200 | 16 | 3200 | 2° | 7 | 20-800 | 15 |

| QC12K-16×4000 | 16 | 4000 | 2° | 5 | 20-800 | 22 |

| QC12K-20×2000 | 20 | 2000 | 2°30' | 8 | 20-800 | 22 |

| QC12K-20×2500 | 20 | 2500 | 2°30' | 6 | 20-800 | 22 |

| QC12K-20×3200 | 20 | 3200 | 2°30' | 6 | 20-1000 | 30 |

| QC12K-20×4000 | 20 | 4000 | 2°30' | 6 | 20-1000 | 30 |

| QC12K-25×2000 | 25 | 2000 | 3° | 6 | 20-1000 | 30 |

| QC12K-25×2500 | 25 | 2500 | 3° | 6 | 20-1000 | 30 |

| QC12K-25×3200 | 25 | 3200 | 3° | 6 | 20-1000 | 30 |

| QC12K-30×2500 | 30 | 2500 | 3°30' | 6 | 20-1000 | 37 |

| QC12K-30×3200 | 30 | 3200 | 3°30' | 5 | 20-1000 | 37 |

| QC12K-40×2500 | 40 | 2500 | 4° | 5 | 20-1000 | 55 |

| QC12K-40×3200 | 40 | 3200 | 4° | 5 | 20-1000 | 55 |

| QC12K-50×3000 | 50 | 3000 | 4° | 5 | 90×3 | |

| QC12K-50×6000 | 50 | 6000 | 4° | 5 | 90×5 | |

| QC12K-60×3500 | 60 | 3500 | 4° | 5 | 90×4 |

Note: The technical parameters are subject to change without prior notice.

Links:https://www.globefindpro.com/products/82946.html