Open Back Inclinable Press

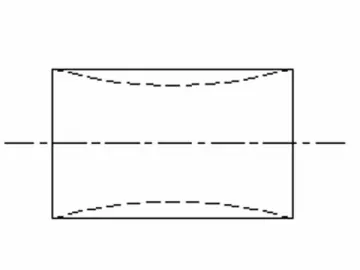

J23 series open back inclinable press is a kind of gap-frame press that is widely used for punching small sized components with high requirement on precision. It is often used in industries such as computer, automobile, rotor and stator, electronic product, communication device, household appliance, etc.

This range of sheet metal stamping press has advantages such as large working load, great shock resistance as well as stable and reliable performance. Single stroke and continuous working are both available.

Our J23-80 and above models of open back inclinable press are equipped with the balancing cylinder to offset the weights of slide and upper die, preventing leading phenomenon of drive system caused by inverse force. As a result, the motion is very stable, and the gap between connecting rod and slide is also removed. Meanwhile, the impact and abrasion of component that bears force are reduced, and the service life of component is prolonged. In addition, the sheet metal forming press can also effectively avoid the slide drop caused by brake failure or connection rod breakage, thus keeping operator and the machine press away from danger.

Features

1. Our open back inclinable press is made from special cast iron alloy, offering good rigidity and shock resistance.

2. The slide runs on a long guide rail, and the application of balancing device for slide ensures stable and precise running.

3. This range of metal forming equipment is designed with an electronic auto lubrication system, thus ensuring periodical lubrication of wearing parts. It will shut down automatically if it lacks of lubrication oil.

4. The gear, gear shaft, crank shaft and other wearing parts are all processed by hardening and lapping treatments to obtain high abrasive resistance as well as balancing property. Thus, excellent machining precision is achieved.

5. The adjusting mechanism for slide is as accurate as 0.1mm. So, the production is safe and swift.

6. This open back inclinable press makes use of highly sensitive clutch and brake along with internationally advanced duplex solenoid valve and overload protection device, guaranteeing the safe and precise running of slide.

7. The transmission center and machine center are almost the same, so precise stamping is achieved. Meanwhile, two slide balancers are used to assure the stable running of the stamping press.

8. The open back inclinable press is able to work with any auto feeding device to realize automatic production. Hence, the working efficiency is improved whilst the cost is cut down. In addition, this environment friendly equipment adopts advanced design theory, and it possesses many other characteristics, such as low noise, low energy consumption, etc.

Technical Parameters

| Item | Unit | JG23-40D | JG23-63D | JG23-80D | |

| Rated pressure | kN | 400 | 630 | 800 | |

| Stroke at rated pressure | mm | 4 | 4 | 5 | |

| Slide stoke | mm | 20-120 | 20-120 | 10-130 | |

| Stoke number | mm | 55 | 50 | 45 | |

| Max. die set height | mm | 220 | 260 | 280 | |

| Die set height adjustment | mm | 70 | 80 | 80 | |

| Distance from slide centre to frame | mm | 260 | 260 | 270 | |

| Worktable dimension (W×L) | mm | 480×710 | 480×710 | 520×860 | |

| Blanking hole size (diameter × depth) | mm | Φ180 | Φ180 | Φ180 | |

| Bolster thickness | mm | 80 | 90 | 100 | |

| Hole diameter in bed (diameter×FB×LR) | mm | Φ200×150×300 | Φ250×200×340 | Φ250×200×340 | |

| Bottom surface size of slide (W×L) | mm | 270×320 | 280×320 | 280×380 | |

| Handle hole size (diameter × depth) | mm | Φ50×70 | Φ50×80 | Φ60×75 | |

| Max. Tilting angle of machine body | ° | 25 | 25 | 20 | |

| Distance between columns | mm | 300 | 350 | 410 | |

| Motor power | Type | kW | Y132M1-6 | Y132M2-6 | Y160M3-6 |

| Power | 4 | 5.5 | 7.5 | ||

| Overall dimension (L×W×H) | mm | 1600×1180×2310 | 1810×1350×2640 | 1810×1410×2790 | |

Links:https://www.globefindpro.com/products/82947.html