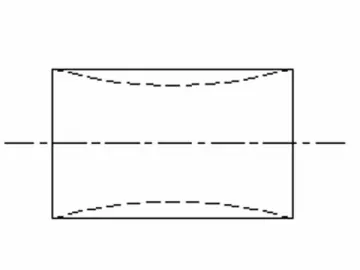

Copper Finned Tube

The fins can be acquired, after the outer surface of a plain tube is roll-formed. This process can help increase the strength of the finned sections, but the plain ends and lands are still soft. High-finned tubes call for those materials that can be cold-worked easily, such as aluminum and copper. Both aluminum and aluminum alloys allow up to 13mm in fin height, while the copper achieves the height of 10mm. If the finned tubes are obliged to fit themselves for bending and coiling, they will go through soft annealing process necessarily.

We adopt pipe mill to create the successive screw fins upon seamless pipe, so as to make our highly efficient heat exchange pipe. The product, including both the pipe body and fins, is made of single metal material, so it does not have the contact electrical resistance, but have the good heat conductivity, high mechanical strength, remarkable vibration resistance and heat swelling property. It is widely applied in the petrochemical industry, metallurgy power generation and food process fields, as well as the ship and central air conditioning system.

Our company mainly chooses the pure copper or copper alloy to make the high efficient heat exchanging pipe. For the purpose of enhancing the heat conductivity of the copper finned tube further, we already developed the straight type with 8mm high fins and the coiled type which has the minimum bending diameter of 15mm.

Specification

| Product | Copper finned tube (available for coiling) |

| Outer tube diameter | 13mm -55mm |

| Inner tube diameter | More than 11mm |

| Fin thickness | 0.3mm -0.4mm |

| Pipe end wall thickness | More than 0.65mm |

| Outer sectional area/ Inner sectional area | More than 5 |

Note: The customization of specification and material is possible.

Related Names

China Fin Pipe | Heat Exchanging Tube | Energy Transfer Pipe Manufacturer

Links:https://www.globefindpro.com/products/82948.html

-

Single Column Hydraulic Press

Single Column Hydraulic Press

-

Double Action Hydraulic Press

Double Action Hydraulic Press

-

Bimetallic Finned Tube (Steel & Aluminum)

Bimetallic Finned Tube (Steel & Aluminum)

-

Sheet Metal Shear

Sheet Metal Shear

-

Hydraulic Guillotine Shear

Hydraulic Guillotine Shear

-

Copper Finned Tube Condenser

Copper Finned Tube Condenser

-

Open Back Inclinable Press

Open Back Inclinable Press

-

CNC Hydraulic Swing Beam Shear

CNC Hydraulic Swing Beam Shear

-

SC200/200 Construction Hoist

SC200/200 Construction Hoist

-

3 Roll Plate Bending Machine

3 Roll Plate Bending Machine

-

Electric Control Box

Electric Control Box

-

DIN 85-90

DIN 85-90