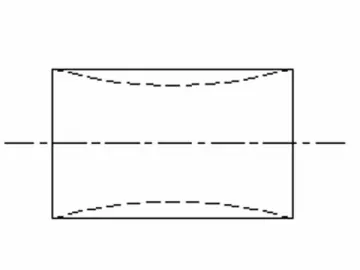

Single Column Hydraulic Press

JWY41 series single column hydraulic press is used for calibration of shaft and similar components. It can also be utilized as a hydraulic blanking press, metal drawing machine, or stamping press to fulfill different sheet metal processing tasks.

This metal forming equipment allows for simple operation, which involves cooperative work of hand and foot. Due to the adoption of integrated cartridge valves for the hydraulic system, the machine press shows advantages such as compact structure, sensitive and reliable action, small power and low noise.

Features

1. This single column hydraulic press uses an independent electrical control box to realize centralized control.

2. The power supply is 380V/50Hz, and the control power supply is 220V.

3. This range of sheet metal machinery has two operation modes which are adjustment mode and semi-automatic mode, and it can work at fixed pressure or fixed stroke.

4. For the semi-automatic mode, drawing and common processing are both available. Moreover, the impulse pressing treatment contains single-stroke and multi-stroke pressing modes, and the time is adjustable.

5. The hydraulic press is fitted with a contactless photoelectric switch for the slide stroke adjustment, and a pressure regulating valve for the control of main cylinder pressure. Additionally, it adopts a time relay for pressure holding time control.

Technical Parameters

| Model | JWY 41- 6.3 | JWY 41- 10 | JWY 41- 16 | JWY 41- 25 | JWY 41- 40 | JWY 41- 63 | JWY 41- 100 | JWY 41- 160 | JWY 41- 200 | JWY 41- 315 | JWY 41- 400 | JWY 41- 500 | JWY 41- 630 | JWY 41- 800 | |||

| Rated pressure | kN | 63 | 100 | 160 | 250 | 400 | 630 | 1000 | 1600 | 2000 | 3150 | 4000 | 5000 | 6300 | 8000 | ||

| Max.workingpressure of liquid | Mpa | 8 | 12.5 | 20 | 16 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | ||

| Slide stroke | mm | 250 | 250 | 400 | 400 | 400 | 500 | 600 | 700 | 700 | 800 | 800 | 900 | 900 | 900 | ||

| Open height | mm | 400 | 400 | 500 | 630 | 630 | 750 | 800 | 900 | 1000 | 1100 | 1250 | 1300 | 1500 | 1500 | ||

| Throat depth | mm | 200 | 200 | 250 | 350 | 350 | 320 | 400 | 420 | 450 | 800 | 1500 | 1500 | 1500 | 1500 | ||

| Slide speed | Down | mm/s | 80 | 80 | 120 | 100 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | ||||

| Pressing | mm/s | 18~20 | 20~22 | 18~20 | 18~20 | 18~20 | 18~20 | 15~20 | 10~12 | 10~15 | 8~10 | 8~10 | 10~15 | 6~10 | 5~8 | ||

| Return | mm/s | 55 | 50 | 50 | 75 | 75 | 100 | 100 | 100 | 70 | 60 | 55 | 70 | 60 | 45 | ||

| Workingtable size | Left-Right | mm | 440 | 440 | 500 | 580 | 700 | 710 | 800 | 800 | 900 | 1500 | 2000 | 2500 | 2500 | 3000 | |

| Front-Back | mm | 380 | 380 | 450 | 570 | 570 | 600 | 700 | 700 | 900 | 1500 | 1800 | 2000 | 2000 | 2400 | ||

| Table heightabove floor | mm | 700 | 700 | 710 | 710 | 710 | 810 | 800 | 800 | 900 | 400 | 400 | 400 | 400 | 400 | ||

| Dimensionsofblankinghole | mm | Φ100 | Φ100 | Φ100 | |||||||||||||

| Main motor power | kW | 3 | 3 | 4 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 15 | 22 | 22 | 2×22 | 2×22 | 2×22 | ||

Note: The parameters are subject to change without prior notice.

Links:https://www.globefindpro.com/products/82949.html

-

Double Action Hydraulic Press

Double Action Hydraulic Press

-

Bimetallic Finned Tube (Steel & Aluminum)

Bimetallic Finned Tube (Steel & Aluminum)

-

Sheet Metal Shear

Sheet Metal Shear

-

Hydraulic Guillotine Shear

Hydraulic Guillotine Shear

-

Copper Finned Tube Condenser

Copper Finned Tube Condenser

-

Four Column Hydraulic Press

Four Column Hydraulic Press

-

Copper Finned Tube

Copper Finned Tube

-

Open Back Inclinable Press

Open Back Inclinable Press

-

CNC Hydraulic Swing Beam Shear

CNC Hydraulic Swing Beam Shear

-

SC200/200 Construction Hoist

SC200/200 Construction Hoist

-

3 Roll Plate Bending Machine

3 Roll Plate Bending Machine

-

Electric Control Box

Electric Control Box