Hydraulic Guillotine Shear

1. The QC11Y series hydraulic guillotine shear has a frame that is welded by steel plates, and the internal stress of the frame is eliminated due to annealing and Vibratory Stress Relief treatments.

2. The hydraulic shearing machine is equipped with an advanced integrated hydraulic system to enhance performance reliability.

3. For reduced distortion of sheet metal, the hydraulic shear supports setting different shearing angles within a certain range.

(1) The shearing angle adjustment is realized by the hydraulic control system. The metal plate shearer is designed with a button to support automatic shearing angle regulation. Operator just needs to release the button after obtaining appropriate shearing angle.

(2) The shearing angle varies with the sheet thickness. When the shearing angle is larger, the required shearing force is smaller; while smaller shearing angle creates less distortion.

4. This hydraulic guillotine shear uses a guide sign for blade clearance adjustment, and the hand wheel adjustment method is swift and accurate. This function is achieved on the control panel, and the adjustment is very convenient.

5. Hydraulic drive and energy accumulator are both adopted to deliver reliable performance and easy operation.

(1) The design ensures stable upper tool post return and workpiece-holding pressure. The stable pressure allows tight and secure workpiece clamping, ensuring high shearing precision.

(2) As we know, if the nitrogen gas is reduced to a certain level, the return stroke force and workpiece holding force will drop down below permitted values. However, our range of hydraulic guillotine shear can keep the nitrogen gas for several years because of the outstanding sealing property, and desired pressure will be obtained simply by pressing relevant buttons on the control panel. In a word, this is no need to add nitrogen gas.

6. The hydraulic guillotine shear features a four-edge cutting blade. On top of this, all the blades are exchangeable regardless of upper ones or lower ones, and their service life is very long.

7. The upper tool post for the sheet metal cutting machine adopts inner-inclined structure which facilitates blanking and improves processing accuracy. Meanwhile, it moves vertically to cut the sheet, and it is very safe.

8. Our hydraulic guillotine shear has a rolling guide with three-point support structure, and the supporting gap is reduced to enhance shearing quality.

(1) Three rolling bearings are arranged in a triangular shape, creating good stability. The rolling friction shows the characteristics of little abrasion as well as small friction force.

(2) The metalworking shear adopts a few belleville springs to automatically compensate and remove the gap generated by friction.

9. This hydraulic guillotine shear can adjust stroke number on the basis of sheet length, and the tool post returns automatically exactly when shearing process is finished. Hence, unnecessary abrasion is avoided, and the manufacturing efficiency is enhanced.

10. The backgauge is motor-driven and supports digital display.

(1) The backgauge system adopts a rotary encoder to transfer position signals to the digital displayer, thus displaying the position digitally and accurately. The adoption of imported digital displayer ensures low failure rate and effectively avoids disturbance caused by circuit noise.

(3) Additionally, the backgauge offers buffering function to relieve impact force between metal sheet and back plate, minimizing the distortion of back plate. So, the hydraulic shearing machine offers high shearing accuracy.

11. This hydraulic guillotine shear also takes safe production into consideration, and fixed fences are applied to protect people from involving in any accidents.

Technical Parameters

| Model | Sheet width (mm) | Strokenumber (min-1) | Backgaugerange (mm) | Shear angle | Work table height (mm) | Main motor power (kW) |

| Q11Y-6×2500 | 2500 | 16-35 | 20-600 | 30'-1°30' | 760 | 7.5 |

| Q11Y-6×3200 | 3200 | 14-35 | 20-600 | 30'-1°30' | 770 | 7.5 |

| Q11Y-6×4000 | 4000 | 10-30 | 20-600 | 30'-1°30' | 770 | 7.5 |

| Q11Y-6×5000 | 5000 | 10-30 | 20-800 | 30'-1°30' | 800 | 11 |

| Q11Y-6×6000 | 6000 | 8-25 | 20-800 | 30'-1°30' | 800 | 11 |

| Q11Y-8×2500 | 2500 | 14-30 | 20-600 | 30'-2° | 800 | 11 |

| Q11Y-8×3200 | 3200 | 12-30 | 20-600 | 30'-2° | 800 | 11 |

| Q11Y-8×4000 | 4000 | 10-25 | 20-600 | 30'-2° | 800 | 11 |

| Q11Y-8×5000 | 5000 | 10-25 | 20-800 | 30'-2° | 850 | 15 |

| Q11Y-8×6000 | 6000 | 8-20 | 20-800 | 30'-2° | 850 | 15 |

| Q11Y-12×2500 | 2500 | 12-25 | 20-800 | 30'-2°30' | 820 | 15 |

| Q11Y-12×3200 | 3200 | 12-25 | 20-800 | 30'-2°30' | 870 | 15 |

| Q11Y-12×4000 | 4000 | 8-20 | 20-800 | 30'-2°30' | 870 | 15 |

| Q11Y-12×5000 | 5000 | 8-20 | 20-1000 | 30'-2°30' | 900 | 22 |

| Q11Y-12×6000 | 6000 | 6-20 | 20-1000 | 30'-2°30' | 950 | 30 |

| Q11Y-16×2500 | 2500 | 12-20 | 20-800 | 30'-2°30' | 800 | 15 |

| Q11Y-16×3200 | 3200 | 12-20 | 20-800 | 30'-2°30' | 860 | 15 |

| Q11Y-16×4000 | 4000 | 8-15 | 20-800 | 30'-2°30' | 870 | 22 |

| Q11Y-16×5000 | 5000 | 8-15 | 20-800 | 30'-2°30' | 1000 | 30 |

| Q11Y-16×6000 | 6000 | 6-15 | 20-1000 | 30'-2°30' | 1100 | 37 |

| Q11Y-20×2500 | 2500 | 10-20 | 20-1000 | 30'-3° | 870 | 30 |

| Q11Y-20×3200 | 3200 | 10-20 | 20-800 | 30'-3° | 920 | 30 |

| Q11Y-20×4000 | 4000 | 8-15 | 20-800 | 30'-3° | 1100 | 30 |

| Q11Y-20×5000 | 5000 | 8-15 | 20-800 | 30'-3° | 1200 | 37 |

| Q11Y-20×6000 | 6000 | 6-15 | 20-1000 | 30'-3° | 900 | 37 |

| Q11Y-25×2500 | 2500 | 8-15 | 20-1000 | 30'-3°30' | 870 | 37 |

| Q11Y-25×3200 | 3200 | 8-15 | 20-800 | 30'-3°30' | 900 | 37 |

| Q11Y-25×4000 | 4000 | 6-12 | 20-800 | 30'-3°30' | 1000 | 37 |

| Q11Y-30×2500 | 2500 | 6-12 | 20-1000 | 30'-4° | 1000 | 37 |

| Q11Y-30×3200 | 3200 | 8-12 | 20-1000 | 30'-4° | 1100 | 37 |

| Q11Y-40×2500 | 2500 | 4-10 | 20-1000 | 30'-4° | 1200 | 55 |

| Q11Y-40×3200 | 3200 | 4-10 | 20-1000 | 30'-4°' | 1200 | 55 |

Note: The technical parameters are subject to change without prior notice, and the values are in accordance with final agreement.

Links:https://www.globefindpro.com/products/82954.html

-

Copper Finned Tube Condenser

Copper Finned Tube Condenser

-

Four Column Hydraulic Press

Four Column Hydraulic Press

-

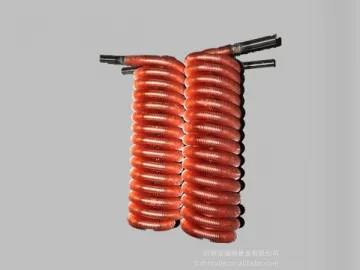

Copper-Nickel Finned Tube

Copper-Nickel Finned Tube

-

Aluminum Finned Tube Condenser

Aluminum Finned Tube Condenser

-

Aluminum Finned Tube

Aluminum Finned Tube

-

27.5 Medium-High Copper Finned Tube

27.5 Medium-High Copper Finned Tube

-

Sheet Metal Shear

Sheet Metal Shear

-

Bimetallic Finned Tube (Steel & Aluminum)

Bimetallic Finned Tube (Steel & Aluminum)

-

Double Action Hydraulic Press

Double Action Hydraulic Press

-

Single Column Hydraulic Press

Single Column Hydraulic Press

-

Copper Finned Tube

Copper Finned Tube

-

Open Back Inclinable Press

Open Back Inclinable Press