CNC Hydraulic Guillotine Shear

As a newly developed sheet metal machinery of our company, the QC11K series CNC hydraulic guillotine shear selects outsourcing components from reliable suppliers, and the components include motor, oil pump, display screen, hydraulic valve, etc. It has the same main machine as QC11Y hydraulic shearing machine, but is equipped with a CNC system.

CNC System

The CNC system is provided by ESTUN and is especially designed for this metal plate shearer. It allows the hydraulic guillotine shear to operate with fast speed, high precision as well as good stability, and can accurately control the movement of backgauge. The ESTUN CNC control system also achieves other functions, such as precision compensation, auto detection, etc.

1. The CNC system has a 320×240 LCD display whose brightness can be adjusted, and the screen is also resistant to scratch, oil, acid and radiation. The viewing angle is large, and the keyboard has an IP rating of IP65.

2. An USB port is included in the standard configuration. Hence, the sheet metal shear supports storage of all the programs and relevant parameters on personal computers or network computers with the help of a USB flash drive.

3. The CNC system makes the hydraulic guillotine shear convenient for operation, and supports direct parameter inputting.

Product Details

1. This CNC hydraulic guillotine shear features a steel plate welded frame, and the frame undergoes annealing and VSR treatments to eliminate stress and enhance stability.

2. The hydraulic drive and energy accumulator allow for convenient operation and reliable performance.

(1) Due to this design, the return stroke speed of upper tool post and the pressure of work holding cylinder are very stable, preventing undesired movement of metal sheet during working. This is one of the reasons why this sheet metal cutting machine provides such high processing accuracy.

(2) Thanks to the excellent sealing property, the nitrogen gas inside the guillotine shear can be kept for several years, and the problems of low return stroke force and work holding force caused by insufficient nitrogen gas are both avoided. Thus, there is no need to add nitrogen gas, and user just needs to press the fluid adding button on the operation panel until the pressure reaches up to ideal value.

3. The state-of-the-art integrated hydraulic system further enhances the reliability of the CNC hydraulic guillotine shear.

4. This sheet metal fabrication equipment is available with a guide sign for blade clearance adjustment, and the hand wheel adjustment method ensures fast, accurate and convenient operation.

This function is set on the control panel right in front of this metalworking cutting tool, and user can type in data during operation. This convenient adjustment improves production efficiency greatly, and this is very significant for a manufacturer.

5. The CNC hydraulic guillotine shear supports adjustable shear angle so as to minimize the deflection of metal sheet.

(1) The shear angle adjustment is hydraulically controlled, and the upper tool post will make automatic adjustment after the desired shear angle is put in.

(2) The shear angle should be determined according to sheet thickness and actual application. Bigger shear angle requires smaller shear force, while smaller shear angle generates less deflection.

6. The upper tool post for the CNC hydraulic guillotine shear inclines inwards to facilitate the blanking procedure, and the working accuracy is also improved.

7. The upper tool post moves in the vertical direction, so, the target sheet receives vertical force. The safety factor of shearing is very high, and potential danger is avoided.

8. This CNC hydraulic guillotine shear is able to adjust required strokes according to the length of sheet material, and the tool post will execute return stroke automatically when the sheet is cut. This design is helpful to reduce abrasion of the hydraulic plate shearing machine, increasing production effectiveness.

9. The backgauge is motor-driven, and the data are revealed by a digital display after receiving signals from the rotary encoder.

The rotary encoder features accurate detection with low error rate, and the imported display also has a low failure rate. Furthermore, it won’t be influenced by circuit noise.

10. The backgauge system provides buffering to mechanical force, and this function is used to relieve the impact force between sheet material and backgauge. Thus, the backgauge is well protected from deformation caused by big force, and the desired sheet size won’t be influenced.

11. As for safety, this hydraulic guillotine shear adopts stationary fences to separate people from dangerous areas.

12. The rolling guide has a three-point support structure to eliminate the supporting gap, and the shearing quality is enhanced. The three rolling bearings form triangular shape with good stability, and the rolling friction generates little abrasion and frictional force. There are several belleville springs, and they are used to compensate and remove the gap lead by friction.

13. The hydraulic guillotine shear is equipped with four-edge rectangular blades, and all these cutting edges are suitable for production and have long lifespan. Moreover, all the upper and lower blades can be changed with each other for application.

Technical Parameters

| Model | Sheet thickness (mm) | Sheet width (mm) | Stroke number (min-1) | Backgauge range (mm) | Shear angle | Work table height (mm) | Main motor power (kW) |

| Q11K-6×2500 | 6 | 2500 | 16-35 | 20-600 | 30'-1°30' | 760 | 7.5 |

| Q11K-6×3200 | 6 | 3200 | 14-35 | 20-600 | 30'-1°30' | 770 | 7.5 |

| Q11K-6×4000 | 6 | 4000 | 10-30 | 20-600 | 30'-1°30' | 770 | 7.5 |

| Q11K-6×5000 | 6 | 5000 | 10-30 | 20-800 | 30'-1°30' | 800 | 11 |

| Q11K-6×6000 | 6 | 6000 | 8-25 | 20-800 | 30'-1°30' | 800 | 11 |

| Q11K-8×2500 | 8 | 2500 | 14-30 | 20-600 | 30'-2° | 800 | 11 |

| Q11K-8×3200 | 8 | 3200 | 12-30 | 20-600 | 30'-2° | 800 | 11 |

| Q11K-8×4000 | 8 | 4000 | 10-25 | 20-600 | 30'-2° | 800 | 11 |

| Q11K-8×5000 | 8 | 5000 | 10-25 | 20-800 | 30'-2° | 850 | 15 |

| Q11K-8×6000 | 8 | 6000 | 8-20 | 20-800 | 30'-2° | 850 | 15 |

| Q11K-12×2500 | 12 | 2500 | 12-25 | 20-800 | 30'-2°30' | 820 | 15 |

| Q11K-12×3200 | 12 | 3200 | 12-25 | 20-800 | 30'-2°30' | 870 | 15 |

| Q11K-12×4000 | 12 | 4000 | 8-20 | 20-800 | 30'-2°30' | 870 | 15 |

| Q11K-12×5000 | 12 | 5000 | 8-20 | 20-1000 | 30'-2°30' | 900 | 22 |

| Q11K-12×6000 | 12 | 6000 | 6-20 | 20-1000 | 30'-2°30' | 950 | 30 |

| Q11K-16×2500 | 16 | 2500 | 12-20 | 20-800 | 30'-2°30' | 800 | 15 |

| Q11K-16×3200 | 16 | 3200 | 12-20 | 20-800 | 30'-2°30' | 860 | 15 |

| Q11K-16×4000 | 16 | 4000 | 8-15 | 20-800 | 30'-2°30' | 870 | 22 |

| Q11K-16×5000 | 16 | 5000 | 8-15 | 20-800 | 30'-2°30' | 1000 | 30 |

| Q11K-16×6000 | 16 | 6000 | 6-15 | 20-1000 | 30'-2°30' | 1100 | 37 |

| Q11K-20×2500 | 20 | 2500 | 10-20 | 20-1000 | 30'-3° | 870 | 30 |

| Q11K-20×3200 | 20 | 3200 | 10-20 | 20-800 | 30'-3° | 920 | 30 |

| Q11K-20×4000 | 20 | 4000 | 8-15 | 20-800 | 30'-3° | 1100 | 30 |

| Q11K-20×5000 | 20 | 5000 | 8-15 | 20-800 | 30'-3° | 1200 | 37 |

| Q11K-20×6000 | 20 | 6000 | 6-15 | 20-1000 | 30'-3° | 900 | 37 |

| Q11K-25×2500 | 25 | 2500 | 8-15 | 20-1000 | 30'-3°30' | 870 | 37 |

| Q11K-25×3200 | 25 | 3200 | 8-15 | 20-800 | 30'-3°30' | 900 | 37 |

| Q11K-25×4000 | 25 | 4000 | 6-12 | 20-800 | 30'-3°30' | 1000 | 37 |

| Q11K-30×2500 | 30 | 2500 | 6-12 | 20-1000 | 30'-4° | 1000 | 37 |

| Q11K-30×3200 | 30 | 3200 | 8-12 | 20-1000 | 30'-4° | 1100 | 37 |

| Q11K-40×2500 | 40 | 2500 | 4-10 | 20-1000 | 30'-4° | 1200 | 55 |

| Q11K-40×3200 | 40 | 3200 | 4-10 | 20-1000 | 30'-4°' | 1200 | 55 |

Note: The technical parameters are subject to change without prior notice, and the values are in accordance with final agreement.

Links:https://www.globefindpro.com/products/82967.html

-

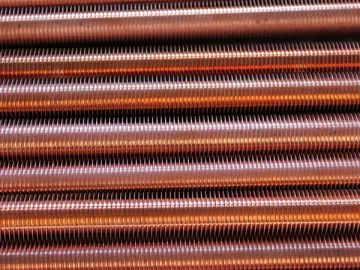

Bimetallic Finned Tube (Copper & Aluminum)

Bimetallic Finned Tube (Copper & Aluminum)

-

Copper Fin Plate

Copper Fin Plate

-

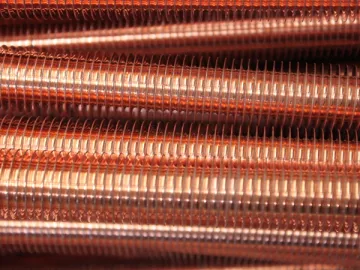

25.5 Medium-High Copper Finned Tube

25.5 Medium-High Copper Finned Tube

-

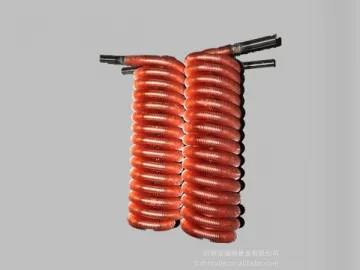

Finned Tube Coil Heat Exchangers

Finned Tube Coil Heat Exchangers

-

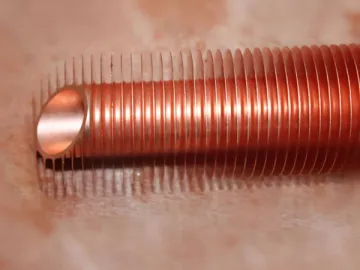

19.05 Medium-High Copper Finned Tube

19.05 Medium-High Copper Finned Tube

-

Aluminum Fin Plate

Aluminum Fin Plate

-

38.5 High Cupronickel Finned Tube

38.5 High Cupronickel Finned Tube

-

17.5 Low Aluminum Finned Tube

17.5 Low Aluminum Finned Tube

-

57 Bimetallic High Finned Tube

57 Bimetallic High Finned Tube

-

47 High Copper Finned Tube

47 High Copper Finned Tube

-

27.5 Medium-High Copper Finned Tube

27.5 Medium-High Copper Finned Tube

-

Aluminum Finned Tube

Aluminum Finned Tube