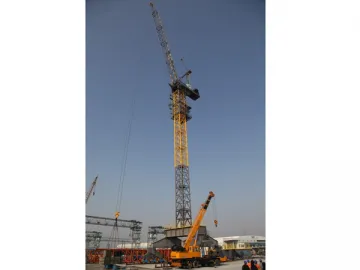

Box Girder Type Gantry Crane

Our FHMG series box girder type gantry crane is specially designed for loading the large scale voltage transformer. Its main steel-structure parts are all connected by high quality flanges, and can be disassembled fast and conveniently to adapt to the long distance transportation. It consists of the main girder, inferior cross girder, landing legs, primary tie beam, secondary tie beam, walking trolley, crane carriage, platform railing, and electrical control system.

Technical Parameters

| Rated load | 400t | Leg span | 33m | ||

| Working class | A4 | Lifting height | 18m | ||

| Cart cardinal distance | 8000mm | Crab track distance | 5000mm | ||

| Gross power | 391kW | Main hook boundary position | 3000mm /3560mm | ||

| Max. wheel pressure | 600kN | Gross weight | 384t | ||

| Structural type | Box | Explosion proof | / | ||

| Operation method | Cabinet/Wireless | Crane hook | Ramshorn | ||

| Main hook | Lifting height | 18m | Electric motor | QABP355M6-B 1488r/min/1 | |

| Lifting speed | 2m /min | Power | 200kW | ||

| Rated load capacity | 400t | Working class | M4 | ||

| Gearbox model | ML4PSF130 | Transmission ratio | i=180 | ||

| Drum diameter | 1382mm | Fixed pulley diameter | 660mm | ||

| Steel wire model | 35 ×P7-200G (WA) (dextral plus sinistral) | Steel wire specification | φ30/270m 270m | ||

| Auxiliary hook | Lifting height | 19m | Electric motor model | QABP315M8A | |

| Lifting speed | 4.2m /min | Power | 75kW | ||

| Rated load capacity | 75t | Working class | M5 | ||

| Gearbox model | M3PSF70 | Transmission ratio | 80 | ||

| Drum diameter | 726mm | Fixed pulley diameter | 590mm | ||

| Steel wire model | 35×P.WS36 IWRC-200G | Steel wire specification | φ24/250m | ||

| Cart travel | Speed | 22.6m /min | Power | 12 ×5.5kW | |

| Working class | M5 | Transmission ratio | 121.46 | ||

| Gearbox model | KA107TDV132S4/BMG | Track steel | QU120 | ||

| Wheel diameter | 600mm | ||||

| Crab travel | Speed | 22.6m /min | Power | 4*7.5kW | |

| Working class | M4 | Transmission ratio | 117.94 | ||

| Gearbox model | FA107GDV132M4/BM | Track steel | QU120 | ||

| Wheel diameter | 600mm | ||||

| Power supply | Voltage | 380V | Wind pressure | Mon working condition | 600Pa |

| Frequency | 50Hz | Working condition | 150Pa | ||

| Environmental temperature | -10~45 ℃ | ||||

| Design standard | GB/T3811-2008 | Production standard | GB/T14406-2011 | ||

1. Framework

The framework, including the girder and double stiff landing legs, adopted the beam, slab and bolting joints with ultrahigh strength, and passed through the computation of advanced finite element structure designer software. Thus it is reasonable in structural design, nice in appearance, and convenient in disassembly and transportation.

2. Hoisting mechanism

The hoisting mechanism of our gantry crane owns the high quality configuration. E.g. the SEW branded gearbox shows the high reliability and excellent performance. The new quincunx elastic coupling is superior in vibration buffing. The ABB branded variable frequency electric motor performs perfectly in the impact resistance. The auto braking system consists of the reliable electro-hydraulic push rod brake and travel end limiter, and can fulfill that the electrical braking comes first and the mechanical braking comes later.

3. Crab travel

The interchangeable traveling mechanisms of the crab adopt the same structure, and can be driven independently. The German SEW branded "three in one" drive unit consists of the hardened gearbox and variable frequency electric motor with magnetic brake. The ends of travel are equipped with the polyurethane buffers. The variable frequency control system can handle the travel speed precisely and smoothly.

4. Cart travel

The cart travel of gantry crane adopts the integration of "three in one" drive unit and flat key shaft, so it is compact in structure, small in size and easy in maintenance.

5. Electrical control system

The modular, centralized electrical control system, including the humanized cabinet and ganged console, can offer the operator a wide view and comfortable operation experience. E.g. the touch-screen display can show the working status of each part of gantry crane, and provide the direction for maintenance.

Tips

1. The customization service is available.

2. Regular inspection and maintenance is recommendable.

3. Lubricating the mechanical joint with 3# general lithium base grease is advisable.

4. The regular inspection of bolts is necessary.

As an experienced box girder type gantry crane manufacturer and supplier in China, Finehope also offers hydraulic climbing formwork, overhead crane for electric power station, 63T luffing jib tower crane, and stationary derrick crane, among others.

Related Names

Portal Crane with Strong System Integrity | Gantry Crane for Power Station | Shipbuilding Crane with Trolley | Box Girder Crane

Links:https://www.globefindpro.com/products/82979.html

-

FZQ2200-100T Luffing Jib Tower Crane (Large-scale construction)

FZQ2200-100T Luffing Jib Tower Crane (Large-scale construction)

-

Ceramic Opaque Frit

Ceramic Opaque Frit

-

FZQ800D-40T Luffing-jib Tower Crane (Large-scale construction)

FZQ800D-40T Luffing-jib Tower Crane (Large-scale construction)

-

Portable Cash Box

Portable Cash Box

-

FZQ800P-40T Topless Tower Crane (Large-scale construction)

FZQ800P-40T Topless Tower Crane (Large-scale construction)

-

Manual Stapler

Manual Stapler

-

Seal Box

Seal Box

-

Truss Type Gantry Crane

Truss Type Gantry Crane

-

13.5 Low Aluminum Finned Tube

13.5 Low Aluminum Finned Tube

-

Aluminum Fin Plate

Aluminum Fin Plate

-

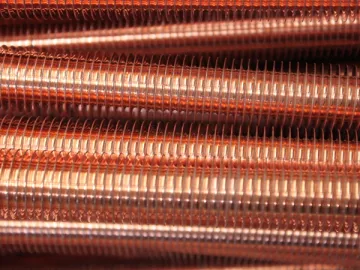

19.05 Medium-High Copper Finned Tube

19.05 Medium-High Copper Finned Tube

-

Finned Tube Coil Heat Exchangers

Finned Tube Coil Heat Exchangers