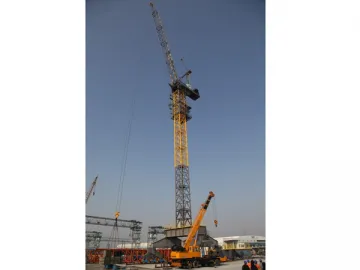

FZQ2200-100T Luffing Jib Tower Crane (Large-scale construction)

The FZQ2200-100T luffing jib tower crane is extensively used to build the thermal, hydro and nuclear power plant, petrochemical plant, metallurgy plant, high building, etc. It can help to erect the tower boiler of the thermal power generator with the power generation capacity of 1000MW or above.

The tower crane with the patent numbers of ZL200620082973.5, ZL200620082974.X, ZL200620084426.0 has quite a number of recommendable features

Technical Parameters

| Rated lifting torque t. m | 2200 | Working grade (GB 3811-83) | A4 | ||

| Rated lifting capacity (T) | Main hook | 100 | Hoisting speed (m/min) | Main hoisting (heavy load) | 0-5.5 |

| Main hook at max. luffing height | 32.8 | Main hoisting (light load ≤ 30t) | 0-8.5 | ||

| Main hook at special working condition | 30 | Aux. hoisting (heavy load) | 0-15.4 | ||

| Auxiliary hook | 16 | Aux. hoisting (light load ≤ 7t) | 0-25 | ||

| Working radius (M) | Main hook | 10-50 | Whole luffing time (min) | 12.7 | |

| Main hook at special working condition | 7-10 | Slewing speed (r/min) | 0-0.16 | ||

| When MH rated lifting capacity at 100t | 10-22 | Slewing angle (r/min) | whole slewing | ||

| Auxiliary hook | 8.7-54 | Rear of platform slewing radius | 15.86 | ||

| Hoisting height (M) | Main hook | 172 | Hydraulic speed (m/min) | 0.4 | |

| Auxiliary hook | 175 | Each jacking stroke | 1.675 | ||

| Max. jib pivot height m | 122 | Total power kW | 270 | ||

| Working condition | |||||

| power supply: three phase five wire system 380V 50/60Hz | |||||

| Calculated wind pressure (N/m 2) | Working condition | 250 | Allowed ambient tem. (℃) | Lowest when working | -20 |

| Non working condition | 800 | Lowest in the locality | -40 | ||

| When jacking erection | 100 | Electric equipment usage | -20~ 40 | ||

| Standard implement: GB 3811-83/DIN EN131001-1: 2004 (priority for the one with high standard between these two) | |||||

Note: 1.The tail shaft of boom has the height of 122m, when the tower crane anchored onto three floors. Meanwhile, the jack-up height can be user regulated.

2. The standard configuration of local power supply system is available.

3. The order of the product with the lowest working temperature of -40℃ should be placed specially.

1. The boom system is an assembly of the interchangeable sections that are formed by the trussed fine-grained alloy steel pipes. These pipes have the light dead weight but the ultrahigh strength of 1000mpa. The jib pivot of boom system adopts the self-aligning rolling bearing, and can be disassembled easily.

2. The box-type pedestal can be fixed onto the solid ground directly without the concrete reinforcement, and there is no stress impacted on the base. The adjustable pedestal applies to the construction site with narrow space where the other type of tower crane can not be erected onto.

3. When the tower crane jacks up to a certain height, it can be anchored onto the building at one floor or multiple floors.

4. The box-type pedestal is not in need of the traditional concrete base, and can be positioned arbitrarily. so the tower crane is capable of working on narrow site.

5. The safeguard system has the functions of load reorganization, failure detection, real-time operation monitoring.

6. The tower mast structural design is one of our patents. It is an assembly of all types of sections with the "HALF" coupling structure.

7. Our modular designed tower crane can be moved economically and conveniently. None of its sections would exceed the load limit of transportation tool, and most of the sections can be stacked up.

As a professional crane manufacturer and supplier, we offer a variety of products that includes luffing jib tower crane, overhead crane, box girder type gantry crane, large lifting device, stationary derrick crane, and more.

Related Names

High Speed Tower Crane | Crane with Automatic Fault Detection | Safe Hoisting Plant

Links:https://www.globefindpro.com/products/82980.html

-

Ceramic Opaque Frit

Ceramic Opaque Frit

-

FZQ800D-40T Luffing-jib Tower Crane (Large-scale construction)

FZQ800D-40T Luffing-jib Tower Crane (Large-scale construction)

-

Portable Cash Box

Portable Cash Box

-

FZQ800P-40T Topless Tower Crane (Large-scale construction)

FZQ800P-40T Topless Tower Crane (Large-scale construction)

-

Manual Stapler

Manual Stapler

-

FHTD1650-35T Inner Climbing Luffing Jib Tower Crane (Large-scale construction)

FHTD1650-35T Inner Climbing Luffing Jib Tower Crane (Large-scale construction)

-

Box Girder Type Gantry Crane

Box Girder Type Gantry Crane

-

Seal Box

Seal Box

-

Truss Type Gantry Crane

Truss Type Gantry Crane

-

13.5 Low Aluminum Finned Tube

13.5 Low Aluminum Finned Tube

-

Aluminum Fin Plate

Aluminum Fin Plate

-

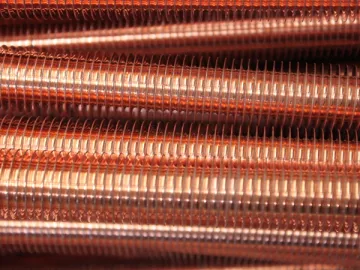

19.05 Medium-High Copper Finned Tube

19.05 Medium-High Copper Finned Tube