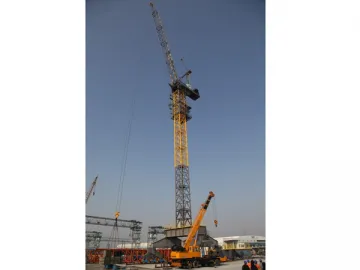

FZQ800P-40T Topless Tower Crane (Large-scale construction)

The FZQ800P-40T topless tower crane is quite different form the traditional tower craning machinery in structural design. It is safe in operation, light in dead weight, high in working performance, good in mechanical sensitivity, and precise in lifting height. It mainly applies to the power plant, shipyard, petrochemical factory, metallurgy plant, and many other places where the industrial equipment need to be positioned precisely. This topless tower crane is the achievement of our ten year's effort in serving the foreign customers, so its thoughtful design can meet the needs of foreign customers well.

Technical Parameters

Performance Parameter Table for Stationary (Undercarriage/Embedded) Mode

| Rated lifting torque t.m | 800 | Working Class (GB/T 3811-2008) | A4 | ||

| Rated Lifting Capacity (t) | Hook | 40 | Lifting Speed (m/min) | Heavy Load 12~40t | 0~21.5 |

| At Max. Radius | 9 | Light Load ≤12t | 0~43 | ||

| Working Radius (m) | Hook | 3.5~70 | Time to Complete One Full Luffing (min) | 2.5 | |

| Slewing Speed (r/min) | 0~0.3 | ||||

| 40t Rated Lifting Capacity | 3.5~20 | Slewing Angle (r/min) | Full Slewing | ||

| Platform Tail Slewing Radius (m) | 25.7 | ||||

| Max. Lifting Height (m) | 4 Fall | ~195 | Hydraulic Jacking Speed (m/min) | 0.4 | |

| 2 Fall | ~390 | One Jacking Stroke (m) | 1.508~1.509 | ||

| Max. Boom Hinged Point Height (m) | 400 | Max. Power (kW) | 300 | ||

| Dead Weight (t) Undercarriage (Four Layers of Anchorage Situation, Max. Boom Hinged Point Height of 150m, Inclusive of Ballast) | 380 | ||||

| Dead Weight (t) Undercarriage (Four Layers of Anchorage Situation, Max. Boom Hinged Point Height 150m, Non-inclusive of Ballast) | 315 | ||||

| Working Condition | |||||

| Power Supply: Three-phase Five-Wire 380V 50Hz | |||||

| Calculated Wind Pressure | Service Condition | 250 | Allowed Ambient Temperature | Lowest at Service Condition | -20 |

| Non-service Condition | 1300 | Lowest at Service Area | -40 | ||

| During Jacking Erection | 100 | Electrical Equipment Service Temp. | 0~ 40 | ||

| Allowed Service Humidity | 1-80% | Allowed Service Altitude | Equal or Lower Than 20000m (If higher than 1000m, motor capacity shall be calibrated.) | ||

| Applicable Standards: GB/T 3811-2008 "Design rules for cranes", GB/T 13752-92 "Design rules for tower cranes" GB 6067-2006 "Safety rules for lifting appliances", JB 4315 "Cranes - Electric control device" GB 5144-2006 "Safety code for tower cranes" | |||||

Performance Parameter Table for Traveling Mode

| Rated lifting torque t.m | 800 | Working Class (GB/T 3811-2008) | A4 | |||

| Rated Lifting Capacity (t) | Hook | 40 | Lifting Speed (m/min) | Heavy Load 12~40t | 0~21.5 | |

| At Max. Radius | 9 | Light Load≤12t | 0~43 | |||

| Traveling Speed m/min | 0~12 | |||||

| Working Radius (m) | Hook | 3.5~70 | Time to Complete One Full Luffing (min) | 4.3 | ||

| Slewing Speed ( r/min) | 0~0.3 | |||||

| 40t Rated Lifting Capacity | 3.5~20 | Slewing Angle (r/min) | Full Slewing | |||

| Platform Tail Slewing Radius (m) | 25.7 | |||||

| Hoisting Height (m) | Hook | ~62 | Hydraulic Jacking Speed m/min | 0.4 | ||

| One Jacking Stroke (m) | 1.508~1.509 | |||||

| Max. Boom Hinged Point Height (m) | 69.7 | Max. Power (kW) | 340 | |||

| Dead Weight (t) (Free Standing Situation, Max. Boom Hinged Point Height of 58.2m) | 285 | |||||

| Working Condition | ||||||

| Power Supply: Three-phase Five-Wire 380V 50Hz | ||||||

| Calculated Wind Pressure | Service Condition | 250 | Allowed Ambient Temperature | Lowest at Service Condition | -20 | |

| Non-service Condition | 1300 | Lowest at Service area | -40 | |||

| During Jacking Erection | 100 | Electrical Equipment Service temp. | 0~ 40 | |||

| Allowed Service Humidity | 1-80% | Allowed Service Altitude | Equal or Lower Than 20000m (If higher than 1000m, motor capacity shall be calibrated.) | |||

| Applicable Standards: GB/T 3811-2008 "Design rules for cranes", GB/T 13752-92 "Design rules for tower cranes" GB 6067-2006 "Safety rules for lifting appliances", JB 4315 "Cranes - Electric control device" GB 5144-2006 "Safety code for tower cranes" | ||||||

Rated Lifting Capacity for MH at Different Radius

| Radius (m) | 20 | 22 | 24 | 26 | 28 | 30 | 32 | 34 | 36 |

| Load (t) | 40 | 36 | 32.7 | 29.9 | 27.5 | 25.5 | 23.6 | 22 | 20.6 |

| Radius (m) | 38 | 40 | 42 | 44 | 46 | 48 | 50 | 52 | 54 |

| Load (t) | 19.3 | 18.2 | 17.2 | 16.2 | 15.4 | 14.6 | 13.9 | 13.2 | 12.6 |

| Radius (m) | 56 | 58 | 60 | 62 | 64 | 66 | 68 | 70 | |

| Load (t) | 12 | 11.5 | 11 | 10.5 | 10 | 9.6 | 9.3 | 9 |

1. The good configuration is the insurance of high quality. All the key parts and components of our topless tower crane are purchased from the world renowned suppliers.

2. In order to adapt our machine to the complex foreign natural environment, we put various poor weather conditions in consideration, such like the rain, high temperature, and moisture. We did a lot in rust proofing, leakage proofing, and electronic elements insulating, as well as the performance testing.

3. In order to adapt our machine to the foreign humanistic environment, we learn about the operation custom of foreign operator, and add a number of humanized functions into the product, such as the collision and interference proof system, multiple three dimensional interlock protection, rough operation protection, capsule style control room with constant temperature, and remote monitoring.

4. In order to adapt our machine to the foreign electric power supply systems and possible emergencies, such like the frequent power failure, voltage fluctuation, irregular wave, and dust pollution. Our topless tower crane adopts the large voltage margin to protect the electrical part from being damaged by electrical surge.

4. None of the parts of our product exceed the dimension or weight limit of highway transportation. The sectional area of our tower is 2.6×2.6m2, which is extremely convenient for the truck to transport.

5. Our patent, quick-type pin connection structure, can simplify the erection of our product greatly.

Tower Crane for Severe Environment | Safe Industrial Crane | Hoisting Machine

Links:https://www.globefindpro.com/products/82984.html

-

Manual Stapler

Manual Stapler

-

FHTD1650-35T Inner Climbing Luffing Jib Tower Crane (Large-scale construction)

FHTD1650-35T Inner Climbing Luffing Jib Tower Crane (Large-scale construction)

-

Manual Pencil Sharpener

Manual Pencil Sharpener

-

FZQ1380-63T Luffing Jib Tower Crane (Large-scale construction)

FZQ1380-63T Luffing Jib Tower Crane (Large-scale construction)

-

Large Lifting Device

Large Lifting Device

-

Upgraded Vinyl Cutter

Upgraded Vinyl Cutter

-

Portable Cash Box

Portable Cash Box

-

FZQ800D-40T Luffing-jib Tower Crane (Large-scale construction)

FZQ800D-40T Luffing-jib Tower Crane (Large-scale construction)

-

Ceramic Opaque Frit

Ceramic Opaque Frit

-

FZQ2200-100T Luffing Jib Tower Crane (Large-scale construction)

FZQ2200-100T Luffing Jib Tower Crane (Large-scale construction)

-

Box Girder Type Gantry Crane

Box Girder Type Gantry Crane

-

Seal Box

Seal Box