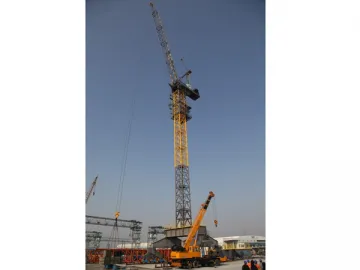

FZQ1380-63T Luffing Jib Tower Crane (Large-scale construction)

Our FZQ1380-63T luffing jib tower crane can be installed in the thermal power plant, to hoist the boiler of 300MW to 1000 MW heat power generator. It can play a useful part on the construction sites with narrow space or complex underground, such like the water and power supply system, petroleum conveyance system, chemical factory, and metallurgy plant. It is also suitable to be installed in the workshop to hoist the heavy stuff.

Technical Parameters

| Max. load torque (t. m) | 1380 | |||

| Max. rated load capacity (t) | Main hook | 63 | ||

| Auxiliary hook | 12.5 | |||

| Max. load height (m) | Main hook | 106 | ||

| Auxiliary hook | 110 | |||

| Max. jib pivot height (m) | 60 | |||

| Jib pivot height in erection (m) | 20 | |||

| Working radius (m) | Main hook | 7~50 | ||

| Auxiliary hook | 12~54 | |||

| Platform tail slewing radius (m) | 16 | |||

| Working speed | Main hoist (m/min) | Heavy load | 0~4.8 | |

| light load | 0~8 | |||

| idle load | 0~20.5 | |||

| Auxiliary hoist (m/min) | 0~15.4 | |||

| Slewing (m/min) | 0~0.15 | |||

| Whole luffing time (min) | 12.7 | |||

| Jacking speed(min) | 0~0.4 | |||

| Power (kw) | Main hoist (JC=40%) | 75/25 | ||

| Auxiliary hoist (JC=40%) | 45 | |||

| Luffing mechanism (JC=25%) | 30 | |||

| Slewing mechanism (JC=25%) | 2 × 4 | |||

| Max. wind pressure (N/ ㎡) | In service | 250 | ||

| Out of service | 800 | |||

| Lowest temperature (℃) | In service | -20 | ||

| Local | -40 | |||

| Input power supply | 415V 50Hz | |||

| Weight (t) | 345(counterweights included) | |||

| Speed regulation type | Frequency conversion | |||

Our tower crane adopts the latest world-class design concept and technology. Its perfect performance in operation safety and cost has already been proven again and again.

1. The new box-type pedestal with cruciate under frame does not have to be reinforced by the concrete base, which can greatly shorten the erection time. The pedestal's pressure against the base is small, so the crane will not affect the base and the under pipeline or other facilities. The pedestal is available for the 360 degree free positioning, and can adapt to the narrow space.

2. The boom system of our tower crane is made of fine-grained ultrahigh strength alloy steel. Its weld seams are finished by special inward arc forming craft, so the stress inside the boon system can be delivered smoothly.

3. The tower section formed by Q345B low alloy steel pipes has the high-strength, light weight, and strong hoisting capacity. It features the "HALF" quick-type truss structure that is fairly convenient to be assembled and disassembled, so the installation time and cost of our tower crane can be reduced greatly. In addition, the tower section can be interchangeable with any section of tower body.

4. The anchoring section can be positioned along the tower arbitrarily, and the small anchoring force will not do harm to the tower section and base.

5. The tower crane has main and auxiliary lifting mechanism. Both the main and auxiliary lifting mechanism adopt the international renowned planetary gearbox, Lebus drum and high strength anti-twisting steel wires, so they are light in weight, small in size, and capable of collecting the wires trimly.

6. The safeguard system of our tower crane can achieve the goal of multiple protection of our equipment, including the force moment protection, load limit,armspan limit, lifting height limit, and mechanical limit. The international renowned-brand force moment limiter has reliable performance and quality. The smart crane monitoring system can realize the load recognition and tower section vertical monitoring.

7. The electronic system has the null-position interlock function. E.g. the normal working state is interlocked with the Jack-up working state. The main lifting device's three speed levels are interlocked with each other. In addition, The electric system can provide the stroke limit, overflow protection, short-circuits protection, under voltage protection, phase sequence protection, force moment protection, etc.

8. The ergonomic-designed control room has the comfortable seat, linkage console and wide visual field.

9. The operator exclusive elevator is an optional auxiliary device. It can help the operator reach the control room fast and safely.

10. None of the components of tower crane exceeds the weight limit of general highway transportation.

As a professional crane manufacturer and supplier, we offer a variety of products that includes luffing jib tower crane, overhead crane, box girder type gantry crane, large lifting device, stationary derrick crane, and more.

Related Names

Tower Crane for Engineering Construction | Flexible Tower Crane | Dismountable Lifting Equipment

Links:https://www.globefindpro.com/products/82989.html

-

Large Lifting Device

Large Lifting Device

-

Upgraded Vinyl Cutter

Upgraded Vinyl Cutter

-

Electric Stapler

Electric Stapler

-

Lockable Key Box

Lockable Key Box

-

FZQ1650-75T Luffing Jib Tower Crane (Large-scale construction)

FZQ1650-75T Luffing Jib Tower Crane (Large-scale construction)

-

Stationary Derrick Crane

Stationary Derrick Crane

-

Manual Pencil Sharpener

Manual Pencil Sharpener

-

FHTD1650-35T Inner Climbing Luffing Jib Tower Crane (Large-scale construction)

FHTD1650-35T Inner Climbing Luffing Jib Tower Crane (Large-scale construction)

-

Manual Stapler

Manual Stapler

-

FZQ800P-40T Topless Tower Crane (Large-scale construction)

FZQ800P-40T Topless Tower Crane (Large-scale construction)

-

Portable Cash Box

Portable Cash Box

-

FZQ800D-40T Luffing-jib Tower Crane (Large-scale construction)

FZQ800D-40T Luffing-jib Tower Crane (Large-scale construction)