Hydraulic Climbing Formwork

The hydraulic climbing formwork for chimney construction is superior over all the traditional forming methods, suck as the derrick turnover type, sliding type, non-derrick sliding type, electric powered lifting type. It is regarded as the most advanced method to build chimney.

The common shortages of the traditional four types of formwork, like the center drift, cylinder torsion, indentation, and surface crack, can be overcome, and the troubles of derrick erection, including the roping, large area occupation, high labor intensity and low work efficiency, can be saved.

Technical Parameters

| Number of lifting frames | 12-24 Pins | |

| Maximum load of single hydraulic cylinder | 8t | |

| Maximum hydraulic cylinder travel | 1.6m | |

| Rated load capacity of lifting cage | 1.2t | |

| Rated load of boom | 0.5t | |

| Working pressure of hydraulic system | 16mpa | |

| Motor power (KW) (JC=40%) | 11 | 22×2 |

| Motor rotary speed (r/min) | 945 | 715 |

| Gearbox transmission ratio | 80 | 63 |

| Steel rope strength (KN) | 20 | 2×12.5 |

| Steel rope even rotary speed (m/min) | 30 | 40 |

| Steel rope diameter ( mm ) | 15 | 17 |

| Retarding torque (N.m) | 200 | 355 |

Tips for maintenance

The normal operation of hydraulic system is associated with the good operation and maintenance custom of operator to a great extent.

1. The fasteners and fixers of oil cylinder should be checked regularly, so as to ensure they never loosen.

2. The sealing property of oil cylinder should be checked regularly. The check way is to see if the non-working rod was sliding down or not. If the answer is yes, there must be the leakage happening on the oil control one-way valve or in the cylinder.

3. A special attention should be paid to the platform when the exterior operation lifting frame is ascending. Any lean of platform or the uneven diagonal tension stress in the steel rope of drum circle should lead to a stop of whole machine.

4. A regular inspection on the dust ring of booster's guide rod is advisable. Lubricate the guide rod via the forced oil feeder.

5. The cleanness of oil is very important. The oil tank should be cleaned totally, when renewing the oil.

6. All the parts of hydraulic system should be protected from corrosion and squeeze, especially for the oil hose.

7. Some measure should be taken to rain proof the hydraulic and electronic systems.

8. The way to tackle the issue of failing to work.

a. Start the motor to make the pump run free.

b. Check the oil pump, and make sure the rotary direction of motor is right. ( C.W. viewing from the driving end)

c. Check the magnetic valve, and see if it is working well.

d. See if the hydraulic pressure existed or not.

Advanced Technology and Unique Structure

1. The derrick and the center drum circle adopt the truss structure with light weight, which can be easily assembled or disassembled.

2. The climbing formwork can be randomly adjusted as the changes in cylinder to ensure the clean and tidy appearance during the construction process.

3. The exterior cylinder concreting and masonry lining can be carried on at the same time, which can greatly enhance the work efficiency and shorten the construction period.

4. The elevator can reach the top of cylinder safely and fast.

Hydraulic Lifting System and Safety Device

1. The hydraulic lifting mechanism adopts the unique synchronization device to ensure the high synchronization and stability in lifting process.

2. The system operation is controlled by PLC automatic program to achieve multiple safety protection and avoid misoperation effectively.

3. The lifting cage is equipped with rope-broken protection device.

4. The climbing formwork is equipped with advanced safety device to realize multiple protection and high reliability.

Technology Innovation of Electric System

1. Electrical control and operating system are integrated in the well-shaped electrical station, which is easy to transport and storage.

2. The lifting cage adopts the advanced speed variation technology, which enables the operation smoothly and stably.

3. The complete communication system can do help to the multiple safety protection.

As a professional crane manufacturer and supplier, we offer a variety of products that includes luffing jib tower crane, overhead crane, box girder type gantry crane, large lifting device, stationary derrick crane, and more.

Related Names

Climbing Formwork with Hydraulic System | Self-climbing Formwork | Automatic Climbing Formwork | Formwork for Vertical Concrete Structure

Links:https://www.globefindpro.com/products/83005.html

-

Printing Frosted Glaze

Printing Frosted Glaze

-

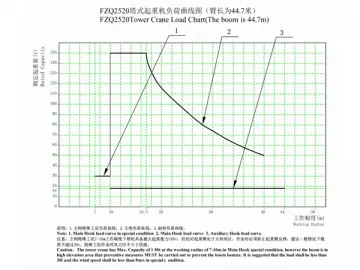

FZQ2520-150T Luffing Jib Tower Crane (Large-scale construction)

FZQ2520-150T Luffing Jib Tower Crane (Large-scale construction)

-

Kater-8101

Kater-8101

-

Manual Hole Punch

Manual Hole Punch

-

Kater-8102

Kater-8102

-

KATER 791

KATER 791

-

High Speed UV Roll to Roll Inkjet Printer

High Speed UV Roll to Roll Inkjet Printer

-

Stationary Derrick Crane

Stationary Derrick Crane

-

FZQ1650-75T Luffing Jib Tower Crane (Large-scale construction)

FZQ1650-75T Luffing Jib Tower Crane (Large-scale construction)

-

Lockable Key Box

Lockable Key Box

-

Electric Stapler

Electric Stapler

-

Upgraded Vinyl Cutter

Upgraded Vinyl Cutter