FZQ2520-150T Luffing Jib Tower Crane (Large-scale construction)

The FZQ2520-150T luffing jib tower crane has many impressive features, including the high luffing height, fast lifting speed, large lifting capacity, extensive working range, strong wind resistant ability, light dead weight, and flexible positioning. It not only applies to the thermal, hydro, nuclear power plants, chemical factory, metallurgy plant, and tall building, but also applies to the narrow construction site where the other kinds of craning machine is hard to be positioned.

Technical Parameters

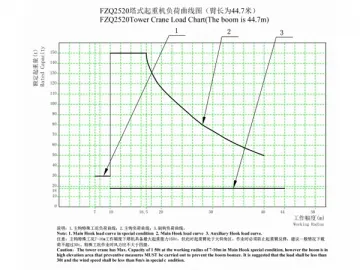

| Max. lifting torque (t. m) | 2520 | |||

| 44.7m | 55.2m | 65.7m | ||

| Max. rated lifting capacity (t) | Main hook | 150 | 112 | 100 |

| Auxiliary hook | 18 | 18 | 18 | |

| Max. lifting height (m) | Main hook | 170 | 180 | 180 |

| Auxiliary hook | 172 | 182 | 192 | |

| Working radius (m) | Main hook | 7-40 | 7-50 | 8.9-60 |

| Auxiliary hook | 8.8-44 | 8.8-54 | 11-64 | |

| Jib pivot height in erection | 138 | 138 | 138 | |

| Hoisting speed | Main hook | 0-10.2 | 0-15.2 | 0-15.2 |

| Main hook | 0-36.6 | 0-36.6 | 0-36.6 | |

| Slewing | 0-0.25 | 0-0.25 | 0-0.25 | |

| Luffing time (min) | 12.7 | 12.7 | 12.7 | |

| Wind pressure calculation | Working condition | 250 | ||

| Non working condition | 1500 | |||

1. The pedestal adopts the cruciate downside frame and spherical-hinged landing legs that can be 360° free adjustable, so it can dodge the barriers reasonably. The ground beneath the pedestal only withstands the press without the balance force, so the concrete reinforcement is not necessary.

2. The tower mast is available to be disassembled into stackable sections, so the transportation can be fairly convenient and the cost can be lowered greatly. The standard section and anchoring section of the tower mast is produced by high precise machinery, and can be interchangeable according to the actual need of construction.

3. The tower crane's boom system is made of the alloy steel with ultrahigh strength and light dead weight, so it can withstand a long torque. To meet the need of different applications, the system provides the short jib, standard jib and long jib for option. The short jib features the large lifting capacity, and the long jib features the broad working scope.

4. The main lifting mechanism, auxiliary lifting mechanism, slewing device, and luffing system, as well as the steel wires are purchased from the world renowned suppliers. Every slewing system is variable speed controlled, so the mechanical actions, like start, stop, and slewing, can be stable and safe.

5. The electrical control system of our tower crane consists of the Siemens S7-300 PLC, ABB ACS800 series variable frequency controller, photoelectrical coder, master controller, various limit switch, variable frequency electric motor, overload protector, and high quality cables. It mainly has the following characteristics.

a. The complete safety guard system of the tower crane includes the force moment protection, overload limit, luffing height limit, mechanical positioning limit, electrical interlock, etc.

b. The centralized electrical control center has the compact structure that can be moved expediently. The air conditioner can keep a comfortable temperature inside the control room.

c. The visual monitoring system with touch screen can show the instant working status of main electrical elements and whole system to help with the maintenance.

d. The climbing lifter helps the operator to reach the control room safely and fast.

e. The remote monitoring system allows the operator to handle the equipment's working status and parameters without being within the control room in person.

As a professional crane manufacturer and supplier, we offer a variety of products that includes luffing jib tower crane, overhead crane, box girder type gantry crane, large lifting device, stationary derrick crane, and more.

Related Names

Crane in Construction of Tall Building | Tower Crane with Protection Device | Heavy Duty Tower Crane

Links:https://www.globefindpro.com/products/83008.html