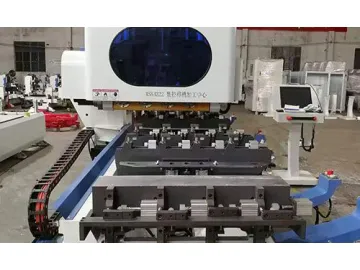

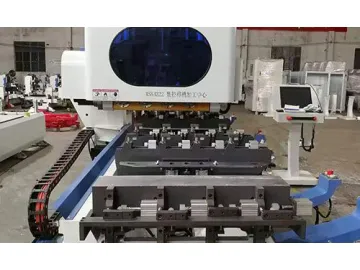

CNC Machining Center for Tenon and Mortise, MSK4322

Samples Technical Data

Features Industrial PC is equipped to accomplish CAD drawing and programming, can meet various needs for machining mortises and tenons with various types and sizes.

Features Industrial PC is equipped to accomplish CAD drawing and programming, can meet various needs for machining mortises and tenons with various types and sizes.

It is possible to equip with 4 rows of different cutting tools, each row of tools can be rotated in 360 degree for processing workpiece in any angle, thus significantly guaranteeing high work efficiency.

Multitude clamps are used for optimal part control.

Automatic lubrication system circulates lubrication to ensure smooth operation and prolonged service life of moveable parts. Clamps 3 sets

3 sets

2 sets, at left and right sides

Precise cutting of surface grooves and curves Precise face milling Precise machining with spiral milling cutter Oblique tenon processing Three way miter joint (Kane Tsugi) processing

| Max. machining length | 4000mm |

| Servo motor power of X-axis | 2.3KW |

| Servo motor power of Y-axis | 1.5KW |

| Servo motor power of Z-axis (with brake) | 2.0KW |

| Servo motor power of B-axis (with brake) | 1.5KW |

| Spindle rotation speed | 18000r/min |

| Spindle power | 5.5kw*4 3.0kw*4 |

| Distance between spindles | 220mm |

| Dimension | 5800*1900*2400mm |

| Weight | 4300kg |

This CNC machining center is able to perform 360-degree machining of workpieces, it can create curved mortise slots, oval mortise slots, specially-shaped mortise slots, as well as various tenons. The CNC tenoner and mortiser machine is an ideal woodworking machine used in redwood mahogany furniture manufacturing industry.

It is possible to equip with 4 rows of different cutting tools, each row of tools can be rotated in 360 degree for processing workpiece in any angle, thus significantly guaranteeing high work efficiency.

Multitude clamps are used for optimal part control.

Automatic lubrication system circulates lubrication to ensure smooth operation and prolonged service life of moveable parts. Clamps 3 sets

3 sets

2 sets, at left and right sides

Precise cutting of surface grooves and curves Precise face milling Precise machining with spiral milling cutter Oblique tenon processing Three way miter joint (Kane Tsugi) processing

Scan QR to Read

Links:https://www.globefindpro.com/products/8325.html

Links:https://www.globefindpro.com/products/8325.html

Recommended Products

-

Smart LED solar street light

Smart LED solar street light

-

Straight Line Rip Saw

Straight Line Rip Saw

-

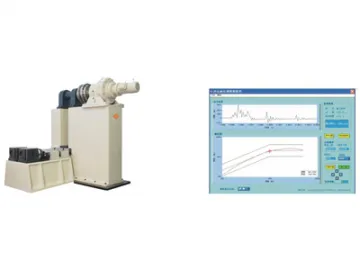

SY-14 Shock Response Spectrum Machine (SRS)

SY-14 Shock Response Spectrum Machine (SRS)

-

SY-15 Incline Impact Tester

SY-15 Incline Impact Tester

-

SY-80 Mechanical Vibration Tester

SY-80 Mechanical Vibration Tester

-

SY-11 Pneumatic Free Fall Shock Machine

SY-11 Pneumatic Free Fall Shock Machine

-

CNC Side Hole Drilling Machine

CNC Side Hole Drilling Machine

-

Manual Band Saw

Manual Band Saw

-

CNC Six-Side Drilling Machine

CNC Six-Side Drilling Machine

-

SY-12 Horizontal Pneumatic Shock Test Machine

SY-12 Horizontal Pneumatic Shock Test Machine

-

Jointer Planer / Surface Planer

Jointer Planer / Surface Planer

-

CNC Wood Router, SK-EPG Series (EPG1313/EPG1318/EPG1325 optional)

CNC Wood Router, SK-EPG Series (EPG1313/EPG1318/EPG1325 optional)