VSA Deoxy Nitrogen Generator

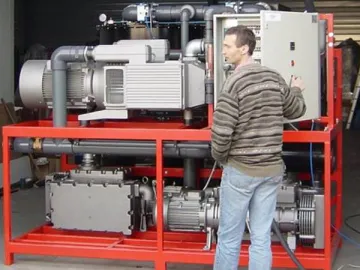

The unique concept of the VSA deoxy nitrogen generator is based on filtration and absorption of oxygen from surrounding air or cold store air by means of a special type of activated carbon. The product consists of 2 vessels with activated carbon, vacuum pump, low-pressure air blower, valve groups and a control box. These components are fixed on a solid frame. Complete with an ingenious control system, this product produces N2 with a high purity in an efficient way.

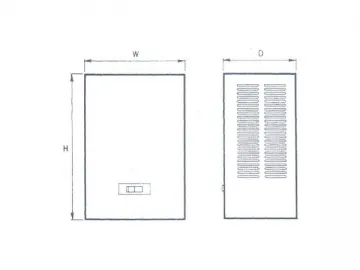

Technical Specifications

| Type | N2 production in 3m3/hr with the content of O2 being approximately 2% without the mixing system | kW |

| 9 | 9 | 20 |

| 13 | 13 | 2.75 |

| 21 | 21 | 4.4 |

| 30 | 30 | 6.0 |

| 55 | 55 | 11.0 |

In 1995, as the first supplier, our company introduced and developed the VSA N2 generator technology for fruit storage. This technology offers considerable advantages for the controlled atmosphere or low oxygen storage system for vegetables and fruits in comparison to the existing (V) PSA and membrane systems.

The nitrogen generating machine is connected to one or more CA or ULO storage rooms. The outside air is sucked inside by way of a PVC piping system. For the production of nitrogen, outside or room air flows through the product at a low overpressure. Then, the oxygen is absorbed by the activated carbon and the concentrated nitrogen will go to the room. At the same time, the present CO2 and ethylene are also absorbed by the activated carbon. An alternate vacuum technology is applied for the regeneration of the absorbed O2¬ and CO2. It is called vacuum swing absorption technology.

Advantages

1. Energy Efficiency

The N2 is produced at a low over pressure of 0.8 bar with the energy saving vacuum technology and advanced processing technology. The pressure of an existing PSA system is almost 10 times higher with a working pressure of approximately 7.5 bar. For production of nitrogen whose purity is 99% with 1% oxygen, membrane systems require a even higher pressure and energy consumption. In conclusion, in comparison to VPSA, PSA and membranes, VSA N2 generator can additionally save energy by about 30 to 60%.

2. 25% Extra Capacity with a Mixing System

The principle of the mixing system is that the oxygen concentration in the room will be decreased more quickly by passing the room air which is mixed with outside air through the VSA N2 generator. Once the oxygen content in the room decreases, the oxygen concentration of the air composition passing through the machine will also reduce. Carrying back the room air improves the capacity with at least 25%.

3. Lower Maintenance Costs and High Reliability

The VSA deoxy N2 generating machine, working with a low pressure vacuum technology, can run smoothly. The N2 or room air doesn’t contact with the oil. Practices have proven the high reliability of the VSA technology. By contrast, the existing systems are characterized by high working pressures and maintenance cost arises owing to necessary high-pressure compressors, frequent filter replacement and oil pollution.

4. Simple Operation

The VSA deoxy N2 generator can be started via 1 option switch for continuous N2 production or for automatic production controlled by an external CA and ULO computer. It has been clearly structured. Quality measuring equipment shows a clear view in the N2 production process.

5. Regulation of Low O2 Level for Modern CA and ULO Storage Systems, like DCS

By using the principle of the mixing system, the nitrogen purity improves while the oxygen content decreases in the room. The nitrogen production stabilizes and can even be adjusted to a higher level. To regulate very low O2 level for CA and ULO storage systems like DCS, the VSA N2 generating device automatically produces N2 with a very high purity. However, if the sucked air has low O2 content, the purity of the produced N2 will be higher.

6. Automatic N2 Transportation System without Extra Tubes and Valves

In case of a combination with the CO2 scrubber, the scrubber tubes can be used for transporting N2 to the rooms and the supply of room air to the VSA N2 generator. The produced N2 will be stored in a lung and periodically blown to the room. At the same time, the room air will be stored in a second lung from which it will be conveyed to the N2 generating unit. With this nitrogen transporting system, the mixing system is put into operation very efficiently.

7. Working with Cold Store Leak Stopping System®, a Unique Concept against Leaky Rooms

The VSA deoxy nitrogen generator can be put into operation automatically to keep the N2 buffer filled. From this buffer, the N2 is being transported via a small air pump to leaky rooms.

Apart from the above developments, we have successfully maintained and stabilized the costs if not decreasing them. Our other products are combined CO2 and O2 scrubbers, cold store leak stopping system, auto store ULO computer for environment regulation, CROSS CO2 scrubber, etc. The accessories for the ULO room include measuring equipment, room leak tester, drained water meter, etc. Our company can also supply advice, design, installation and other services for complete projects.

Related Names

Nitrogen Generating Unit Manufacturer | Long Time Vegetable Storage | CA Storage House Equipment

Links:https://www.globefindpro.com/products/83330.html

-

CO2 Scrubber/ Carbon Dioxide Absorber

CO2 Scrubber/ Carbon Dioxide Absorber

-

E-Light Skin Care Beauty Machine

E-Light Skin Care Beauty Machine

-

Parallel Cooling Units in Controlled Atmosphere Storage

Parallel Cooling Units in Controlled Atmosphere Storage

-

4 Indoor Units with Two Outdoor Units

4 Indoor Units with Two Outdoor Units

-

Humidifier in CA Storage

Humidifier in CA Storage

-

E100F/E101F 4-Indoor Units of Audio Intercom with 1 Outdoor Unit

E100F/E101F 4-Indoor Units of Audio Intercom with 1 Outdoor Unit

-

IIS-1370MC-T-1B Outdoor Camera of 2-Wire Video Door Phone Intercom

IIS-1370MC-T-1B Outdoor Camera of 2-Wire Video Door Phone Intercom

-

IIS-137TV-10B Expander for Outdoor Camera

IIS-137TV-10B Expander for Outdoor Camera

-

IIS-1380EFC-512 Outdoor Camera of Access Control System

IIS-1380EFC-512 Outdoor Camera of Access Control System

-

IIS-135EMC-T-1B Outdoor Camera of 2-Wire Video Door Phone Intercom

IIS-135EMC-T-1B Outdoor Camera of 2-Wire Video Door Phone Intercom

-

Power Supply IIS-660-2B

Power Supply IIS-660-2B

-

Distributor IIS-838FC-512 (for Indoor Monitor)

Distributor IIS-838FC-512 (for Indoor Monitor)