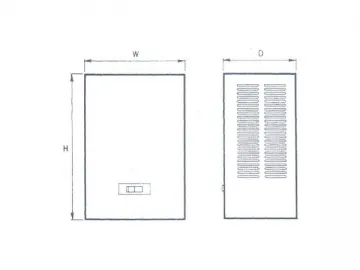

CO2 Scrubber/ Carbon Dioxide Absorber

Our company introduces a new generation of CROSS CO2 scrubber which offers considerable advantages for the vegetable and fruit growers. This carbon dioxide scrubbing device is excellent for ULO storage. Easy to operate, it makes possible each desired CA and ULO environment with the help of the complete technology.

Construction

The CROSS CO2 scrubber consists of a central unit and CO2 absorption vessels. The former is composed of valves large in diameter, two fans and a switchboard. It is connected to 1 or more CO2 absorption compartments. One CO2 compartment is constructed out of 2 vessels filled up with active carbon. The vessels are alternatively used for regeneration and adsorption of the CO2.

Overview of Different Models

| Model | Power (kW) | AbsorbingCapacity (kg) |

| 50 | 0.5 | 50 |

| 90 | 0.5 | 90 |

| 120 | 1.2 | 120 |

| 150 | 1.7 | 150 |

| 200 | 1.7 | 200 |

| 300 | 2.2 | 300 |

| 1000 | 6.2 | 1000 |

| 2000 | 11.0 | 2000 |

| Note: The absorbing capacity can be customized. | ||

CO2 Scrubbing Unit versus Lime

The CO2 scrubbing unit can save a considerable amount of time and money. The desired percentage of O2 and CO2 can be maintained at the right level during the whole storage season. When the lime is used, the CO2 level will be too low for a longer time and the respiration of your products will go much faster. Via such a comparison, CO2 scrubbing system are better for high quality preservation.

Advantages

1. Guaranteed Low Oxygen Operation

After the CO2 is absorbed each time, the activated carbon will be regenerated with outside air. It is well known that CO2 scrubbing device will return an amount of oxygen into the cold store after being regenerated with the outside air. The CROSS CO2 scrubber is equipped with a highly sophisticated control mechanism, which guarantees the return of O2 in the smallest volume.

2. Unique Operation for Perfect Regulation of CO2 Level

According to the working principle of the CO2 scrubbing unit, one vessel is responsible for absorption and the other vessel regenerates continuously. In comparison with a one vessel type scrubbing device, the advantage is that there is no big fluctuation of the CO2 level when each scrubbing operation is done. Therefore, the desirable CO2 percentage can be maintained most exactly.

3. Energy Saving Design

For the structure of the CO2 scrubber, oversized tubes and valves are being used. By enhancing this, a minimum pressure loss through the pipe resistance is created. Subsequently, a minimum amount of energy is required for the air circulation through the installation. These are double advantages for users. The required energy consumption is reduced for the scrubbing equipment and the energy input into the cold store is also reduced, reducing activities of the cooling installation.

4. Auto Store O2 and CO2,Regulation, Temperature Measurement and Regulation (option)

In addition to the standard semi-automatic regulation, the CO2 scrubber can be equipped with an auto store, auto store or auto storeTR system for automatic O2 and CO2 regulation and other CA or ULO functions. Temperature measurement and regulation can be done also with the auto store program. All relevant information about ULO storage will be printed out.

5. Optional Cold Store Leak Stopping System

When the carbon dioxide scrubbing unit aerates a room, the escaped low oxygen air from the room will be stored in a flexible air buffer or lung with the cold store leak stopping system. Via separate supply tubes, this air can be blown to a leaking cold store. In this specific cold store, the O2 level decreases because the leaking effect will be much smaller.

6. Pre-absorbing Program for Extra Low Oxygen Operation (standard)

A cold store with a low O2 level can help the one with a high O2 level via the pre-absorbing program. Thus, low oxygen air will be transferred to the high oxygen room.

7. Aeration Operation (standard)

Each scrubbing unit has standard possibility to aerate a cold store when the content of the O2 within the store is too low.

8. N2 Transportation System Supplying Nitrogen through the Scrubber Piping (option)

The nitrogen from a N2 generating machine will go to the cold store through the tubes of scrubbing unit. This is easily maintained due to the unique combination of the CROSS CO2 absorbing device and buffering system. Without causing air pressure variation in the room, the nitrogen is exchanged with room air in a relatively short time.

9. Absorbing Capacity Expansion Based on the Modular Construction (option)

By enlarging your ULO storage capacity, the CROSS CO2 absorber can easily be enlarged in capacity by simply adding an extra component on location. The ventilators are exchanged and the amount of vessels is increased depending upon the desired absorbing capacity.

10. No Transfer of Ethylene with the Ethylene Stopping System (option)

The CO2 scrubber is designed with 2 sets of vessels. Via the auto store program, the rooms will be absorbed only by module 1 and the other varieties by module 2. Thus, there will be no transfer of the ethylene. The ethylene level in the rooms can be kept low and this is very positive in order to keep hardness of vegetables or fruits.

Despite all these developments, our company has succeeded in maintaining and stabilizing the costs if not decreasing them. The appealing and interesting advantages are solely for the clients.

Related Names

CO2 Removing Device Supplier | Storehouse Carbon Dioxide Concentration | CA System Unit

Links:https://www.globefindpro.com/products/83331.html

-

E-Light Skin Care Beauty Machine

E-Light Skin Care Beauty Machine

-

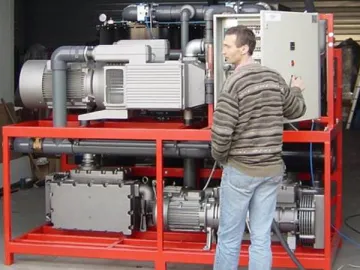

Parallel Cooling Units in Controlled Atmosphere Storage

Parallel Cooling Units in Controlled Atmosphere Storage

-

4 Indoor Units with Two Outdoor Units

4 Indoor Units with Two Outdoor Units

-

Humidifier in CA Storage

Humidifier in CA Storage

-

E100F/E101F 4-Indoor Units of Audio Intercom with 1 Outdoor Unit

E100F/E101F 4-Indoor Units of Audio Intercom with 1 Outdoor Unit

-

Door & Window in CA Storage

Door & Window in CA Storage

-

VSA Deoxy Nitrogen Generator

VSA Deoxy Nitrogen Generator

-

IIS-1370MC-T-1B Outdoor Camera of 2-Wire Video Door Phone Intercom

IIS-1370MC-T-1B Outdoor Camera of 2-Wire Video Door Phone Intercom

-

IIS-137TV-10B Expander for Outdoor Camera

IIS-137TV-10B Expander for Outdoor Camera

-

IIS-1380EFC-512 Outdoor Camera of Access Control System

IIS-1380EFC-512 Outdoor Camera of Access Control System

-

IIS-135EMC-T-1B Outdoor Camera of 2-Wire Video Door Phone Intercom

IIS-135EMC-T-1B Outdoor Camera of 2-Wire Video Door Phone Intercom

-

Power Supply IIS-660-2B

Power Supply IIS-660-2B