Ethylene Scrubber/ Ethylene Absorber

Classification

The CE ethylene scrubber is built in four different sizes for various air volumes. There is a model whose air treatment capacity is 50 and two larger ones with the air treatment capacity being 400 tons. CE 50 can be fixed on the wall, CE 200 and CE 400 inside the room and the CE 400(V400) only outside the room. The air input pressure is 6 bar.

Technical Specifications

| Type | Capacity | L(mm) | W(mm) | H(mm) | Weight(kg) | Power (kW) |

| CE50 | 50 | 350 | 350 | 950 | 80 | 0.5 |

| CE200 | 200 | 500 | 550 | 1600 | 180 | 2.6 |

| CE400 | 400 | 700 | 720 | 1600 | 250 | 3.6 |

| CE400 | 400 | 700 | 720 | 1600 | 250 | 3.6 |

Working Principle

The cold room air is blown inside by one of the fans. The temperature of the central part, the catalyst, is the 230°C or 260°C. It is kept by an electrical heating element. In the catalyst layer, the ethylene is burned. Finally, the air cools down because of the ceramic and go back into the room while is free from any ethylene molecules. The periodical invertion of flow directions makes sure the temperature of the recycled air is close to the room temperature.

Ethylene gas is produced by the respiration of the products and stimulates the ripening and senescence process. The ethylene scrubber we supply here can remove ethylene gas (C2H4) from cold stores, increasing the shelf life of fresh fruits and vegetables. The temperature of the product can be regulated by the user. A timer controls the change in the direction of air circulation.

The application of ethylene scrubber is the most effective and cost efficient way to maintain the ethylene level for conservation of kiwi. It can guarantee a loner storage period for items, like apple, salad, cucumber, pear, tomato, avocado, banana, etc. This allows sellers and wholesales to have marketing flexibility.

Related Names

Ethylene Absorbing Equipment for Sale | Product Storing Technology | Storage System Device

Links:https://www.globefindpro.com/products/83356.html

-

2 Indoor Units with 1 Outdoor Unit

2 Indoor Units with 1 Outdoor Unit

-

Wireless Audio Kits (IIS-V110 IIS-V131)

Wireless Audio Kits (IIS-V110 IIS-V131)

-

IIS-690 30W Power Supply

IIS-690 30W Power Supply

-

Portable IPL Skin Rejuvenation Machine

Portable IPL Skin Rejuvenation Machine

-

Laser Tattoo Removal and Skin Pigment Treatment Machine

Laser Tattoo Removal and Skin Pigment Treatment Machine

-

QF-400 130mm Concrete Saw

QF-400 130mm Concrete Saw

-

IIS-111 Indoor Units of Audio Door Phone Intercom

IIS-111 Indoor Units of Audio Door Phone Intercom

-

IIS-660-2A 33W Power Supply

IIS-660-2A 33W Power Supply

-

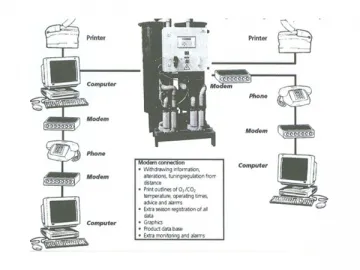

Controlled Atmosphere Storage Control Equipment

Controlled Atmosphere Storage Control Equipment

-

Air Cooler in Controlled Atmosphere Storage

Air Cooler in Controlled Atmosphere Storage

-

IIS-660-3 60W Power Supply

IIS-660-3 60W Power Supply

-

IIS-516F 4 Outdoor Camera Distributor

IIS-516F 4 Outdoor Camera Distributor