Pre-Painted Steel Coil/ Color-Coated (PPGI)

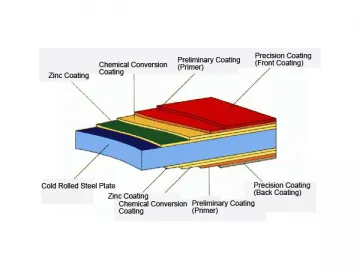

On the continuous unit, the base plate of cold rolled strip steel or galvanized strip steel including the electro galvanized type and hot dipped galvanized type is coated with a layer or several layers of liquid coatings through the roll coating method after the surface pretreatment (containing degreasing and chemical processing). Then, after baking and cooling, the coated steel sheet is made. As a result of the colorful coatings, we customarily call the coil form product as color-coated steel coil. For another, the coating is conducted before the forming process of the steel plate. So, the product is endowed with the name of pre-painted steel plate.

There are many kinds of organic coatings coming with polyester, silicon modified polyester, acrylic acid, plastisol, organosol, etc. With the thickness of 20µm to 100µm, the coating combines with the base plate strongly. It has good waterproof and corrosion resistant performance by resisting the corrosion against the concentrated acid, concentrated alkali and alcohols but poor anticorrosion ability against the organic solvent.

The pre-painted steel coil can be fabricated with diversified colors and patterns like leather, wood grain, textile fabric, etc. in appearance to raise the decorative effect. Its base material of steel strip is mainly the carbon structural sheet of Q195 and Q215 with certain strength, good plasticity as well as excellent processing formability. The product is extensively taken for use in the industrial departments like construction, light industry, automobile, home appliance, etc. It can also be employed for manufacturing the agricultural implement, steel furniture, daily life appliance, etc.

Technological Process

The major production technological processes of the common two coating two baking continuous color coating unit are listed as below.

Uncoiling → Pretreatment → Coating → Baking → Post -treatment → Coiling

Performance and Specification

Zinc Coating Weight of Base Plate

| No. | Use | Base Plate | Zinc Coating Weight(g/m²) | Remark |

| 1 | Building exterior | Hot dipped galvanized steel sheet | 90/90 | Maximum value of 140/140 |

| 2 | Building interior, steel window | Hot dipped galvanized steel sheet | 90/90 | |

| Electro-galvanized steel sheet | 60/60 | |||

| 3 | Home appliance, furniture | Cold rolled steel plate | -- | |

| Electro-galvanized steel sheet | 20/20 |

Type and Corresponding Grade of Base Plate

| Base Plate Type | Standard, Grade and Use of Base Plate | Grade of Color Coated Steel Plate | ||

| Standard | Grade | Use | ||

| Cold rolled steel plate | Q/BQB 402 | SPCC | General use | TSPCC |

| SPCD | Drawing | TSPCD | ||

| Q/BQB 403 | St12 | General use | TSt12 | |

| St13 | Drawing | TSt13 | ||

| Electro-galvanized steel sheet | Q/BQB 430 | SECC | General use | TSECC |

| Home appliance | TSECCB | |||

| SEDC | Drawing | TSECD | ||

| Q/BQB 431 | BLCE Z | General use | TBLCE | |

| BLDE Z | Drawing | TBLDE | ||

| Hot dipped galvanized steel sheet | Q/BQB 420 | St01Z | General use | TSt01 |

| St02Z | Mechanical lock forming | TSt02 | ||

| St03Z | Drawing | TSt03 | ||

| StE280 - 2Z | Structure | TStE28 | ||

| StE345 - 2Z | TStE34 | |||

| Q/BQB 422 | CD51D Z | General use, mechanical lock forming | TDC51D | |

| CD52D Z | Drawing | TDC52D | ||

| S280GD Z | Structure | TS280GD | ||

| S350GD Z | TS350GD | |||

| S550GD Z | TS550GD | |||

| Note: The grade with a G at the end means the base plate for steel window, such as TSt02G, TSECCG and TDC51DG. | ||||

Structure, Surface Condition and Type of Coating

| Classification | Item | Code | |

| Use | Building exterior | JW | |

| Building interior | JN | ||

| Steel window | GC | ||

| Home appliance | JD | ||

| Furniture | JJ | ||

| Other | QT | ||

| Surface condition of coating | Pre-painted steel sheet | TC | |

| Metal embossing plate | YA | ||

| Printed metal sheet | YI | ||

| Type of coating | Polyester | JZ | |

| Silicon modified polyester | GZ | ||

| Polyvinylidene fluoride | KF | ||

| Polyvinyl chloride plastisol | SJ | ||

| Type of base plate | Cold rolled steel plate | LZ | |

| Electro-galvanized steel sheet | DX | ||

| RG | |||

| RW | |||

| Coating structure | Upper surface | Lower surface | -- |

| One coating | One coating | 1/1 | |

| Secondary coating | Secondary coating | 2/1 | |

| Three times coating | Three times coating | 2/2 | |

| Note: The upper surface denotes the front of steel plate and outside surface of steel coil. | |||

Product Grade in Chinese and Japanese Standard Reference Table

| Standard | Q/BQB440 - 1999 | JISG3312-1994 |

| Grade | TSPCCTSt12 | -- |

| TSPCD TSt13 | -- | |

| TSECCTSECCB TBLCE | -- | |

| TSECDTBLDE | ||

| TSt01TSt02TDC51D | CGCC | |

| TSt03TDC52D | CGCD1 | |

| TStE28ts280GD | CGC400 | |

| TStE34TS350GD | CGC440 | |

| TS550GD | CGC570 |

Application

| Construction industry (outdoor) | Factory building, agricultural warehouse, residential prefabricated part, corrugated roof, wall, rain water pipe, balcony railing, newsstand, refrigerated storage, kiosk, rolling shutter door, etc. |

| Construction industry (indoor) | Door, door frame, light steel structure, screen, ceiling, electrical elevator, staircase, ventilation duct, etc. |

| Electrical appliance | Refrigerator, washing machine, switch cabinet, instrument cabinet, air conditioner, microwave oven, bread maker, etc. |

| Furniture | Heating radiator, lamp cover, wardrobe, desk, bed, locker, book shelf, etc. |

| Transportation | Interior decoration of automobile and train, clapboard, container, isolation railing, storehouse separating board in steamship, etc. |

| Others | Whiteboard for writing, dustbin, advertising board, clock, typewriter, instrument panel, weight scale, photographic apparatus, etc. |

Classified Application of Products with Different Coatings

PGS Product with Polyester Resin (table 1)

| Feature | Typical Application | Remark |

| Excellent processability for general use | 1. The exterior material (roof material and wall material) for building in industry, commerce, public facilities and residence 2. The internal material, internal wall material, ceiling board, clapboard and fire protection board in building3. The architectural accessories such as window board and signboard4. Home appliance such as gas boiler, rice barrel, etc. | This type of color coated steel coil has various applications covering building internal and exterior materials, home appliances, etc. |

PCS High Workability Product (table 2)

| Feature | Typical Application | Remark |

| Nice appearance and high workability for home appliances | 1. The home appliances such as refrigerator, electronic stove, washing machine, gas boiler, light implement, display case, drying machine, etc.2. The internal material, internal wall material, ceiling board, clapboard and fire protection board in building | The product has remarkable workability, high chemical resistance, good glossiness and hardness. So, it is mostly taken for manufacturing the home appliance requiring high level appearance quality. |

PVS Salinization Ethylene Product (table 3)

| Feature | Typical Application | Remark |

| Unique building internal and exterior materials with super strong weather resistance, high workability and automatic flame extinction ability | 1. The exterior material (roof material and wall material) for building in industry, commerce, public facilities and residence2. The internal material, internal wall material, ceiling board and clapboard in building3. The industrial machine such as air cooler, industrial robot, etc. | The PVS salinization vinyl resin has excellent resistance to weather chemical and corrosion. The elongation of the coating can get to 300% to 400%. Under any processing condition, it won’t crack easily. The specific embossing effect enables the product with good mechanical property, nice appearance and high durability lasting for over 15 yeas. The PVS pre-painted steel coil (sheet) is the only one which has the automatic flame extinction ability in all the color coated steel plates. So, it is the only optimum choice for use in special area involving chemistry, coast area and sulfur dioxide gas. |

PVDF Fluororesin Product (table 4)

| Feature | Typical Application | Remark |

| Ultra high weather resistance and strong durability lasting for over twenty years | 1. The exterior material (roof material and wall material) for building in industry, commerce, public facilities and residence2. The internal material, internal wall material, clapboard, ceiling board and fireproof door in building | This kind of product is fabricated by making use of the polyvinylidene fluoride resin. It performs more excellently in the long-term resistance to corrosion, weather and chemical than other product in many application areas. |

PSP High Weather Resistant Product (table 5)

| Feature | Typical Application | Remark |

| Outstanding corrosion and weather resistance | 1. The exterior material (roof material and wall material) for building in industry, commerce, public facilities and residence2. The internal material, internal wall material, clapboard and ceiling board in building | The weather resistance of the steel plate is boosted. The pre-painted steel coil is especially appropriate for use as the exterior material in building having high requirements to the resistance to chemical, corrosion and weather. |

Variety of Our Product

| Available Material | TSt01, TSt02, TDC51D, CGCC, etc. |

| Available Specification | 0.2mm-1.5mm in thickness and 700mm-1530mm in width |

| Quality Standard | Enterprise standard, Chinese standard, JIS, DIN, ASTM |

Related Names

Decorative Steel Supplier | Roofing Steel | Metal Coil

Links:https://www.globefindpro.com/products/83439.html

-

Hot Rolled Pickled Plate

Hot Rolled Pickled Plate

-

Wire Rod

Wire Rod

-

Stainless Steel Pipe

Stainless Steel Pipe

-

Steel Billet

Steel Billet

-

ERW Steel Pipe, Electric Resistance Welded Pipe

ERW Steel Pipe, Electric Resistance Welded Pipe

-

Hot Rolled Steel Strip

Hot Rolled Steel Strip

-

Galvanized Steel Pipe

Galvanized Steel Pipe

-

Hot Rolled Steel (Coils)/ Plates /Sheet

Hot Rolled Steel (Coils)/ Plates /Sheet

-

Hot Rolled Steel Square Bar

Hot Rolled Steel Square Bar

-

Seamless Steel Pipe

Seamless Steel Pipe

-

Plate Flange

Plate Flange

-

PX-729 VHF/UHF Two Way Radio Handheld Transceiver

PX-729 VHF/UHF Two Way Radio Handheld Transceiver