Hot Rolled Pickled Plate

Introduction

The hot rolled pickled plate is processed with the hydrochloric acid for descaling from the surface of hot rolled steel plate to get nice and smooth surface. The main processes cover laser welding, stretching and straightening, turbulence pickling, on-line flattening, edge cutting, on-line oiling, etc. The product is generally fabricated with the specification of 1.0mm to 6.0mm in thickness and 800mm to 1650mm in width. It is classified into the low, medium and high levels in terms of the strength and often applied as the material for drawing, automotive structure, etc.

Product Features

1. The hot rolled pickled plate can help the enterprise save the cost by replacing the cold rolled plate.

2. It eliminates the surface oxide scale to generate better surface quality than the ordinary hot rolled steel plate. Meanwhile, the following welding, oiling and painting can be carried out easily.

3. The product has high dimensional accuracy. After the flattening, the plate shape comes out with some changes, thus reducing the deviation of the waviness.

4. The product has high surface finish, strengthening the appearance effect.

Main Uses

1. Auto Industry

The hot rolled pickled plate can be used in the chassis system for trunk frame, vice beam, etc. As to the wheel, it can be taken for manufacturing the rim, wheel rib, etc. The inner plate of the cab can also be fabricated from the product. The product can also be applied for producing the carriage plate, mainly the carriage soleplate of various trucks. In addition, it can be employed for fabricating the stamping parts including the automotive internal small parts such as anti-collision bumper, etc.

2. Mechanical Industry (excluding automobile)

The product can be used for manufacturing textile machinery, mining machinery, draught fan and some general machinery.

3. Light Industrial Electrical Appliances

The hot rolled pickled plate can be used for producing the shell and support of compressor, inner container of water heater, chemical oil drum, etc.

4. Other Uses

We can also take the product to manufacture bicycle parts, sorts of welded pipes, electrical cabinets, highway guardrails, supermarket shelves, storage shelves, fences, iron staircases, as well as various shapes of stamping parts.

| Type | Grade | Reference Grade | |||||

| Steel for wheel | B420CL | ||||||

| Steel for enameling | BTC340R | ||||||

| Steel for cold deformation | QStE340TM | 340XLF | |||||

| QStE380TM | |||||||

| QStE420TM | ZSTE420 | 410XLF | |||||

| Steel for automotive structure | SAPH310 | ||||||

| SAPH370 | |||||||

| SAPH400 | B400PO | ||||||

| SAPH440 | B440PO | ||||||

| SAPH45 | |||||||

| CQ | SPHC | StW22 | A569 | DD11 | C1010 | SAE1010 | C1008 |

| DQ | SPHC | StW23 | A621 | DD12 | |||

| DDQ | SPHC | StW24 | A622 | DD13 | BTC1 | SAE1006 | |

| SDDQ | DD14 | BRC3 | |||||

| Steel for general structure | SS330 | A570 GR30 | |||||

| SS400 | A570 GR33 | ||||||

| St37-2 | 035YLF | ||||||

| St44-2 | |||||||

Delivery Form and Condition

The product is delivered mainly in coil form and in hot rolled state.

Details of Our Product

| Specification | 1.0mm-6.0mm in thickness and 800mm-2000mm in width |

| Material | SPHC |

Related Names

Surface Treated Metal | Passivated Steel | Metal Plate Supplier

Links:https://www.globefindpro.com/products/83440.html

-

Wire Rod

Wire Rod

-

Stainless Steel Pipe

Stainless Steel Pipe

-

Steel Billet

Steel Billet

-

ERW Steel Pipe, Electric Resistance Welded Pipe

ERW Steel Pipe, Electric Resistance Welded Pipe

-

Hot Rolled Steel Strip

Hot Rolled Steel Strip

-

PX-999 Tri-Band Radio Transceiver

PX-999 Tri-Band Radio Transceiver

-

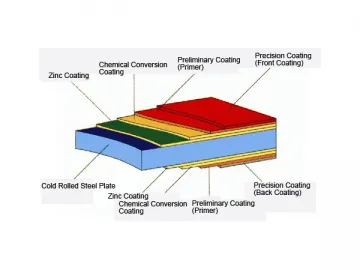

Pre-Painted Steel Coil/ Color-Coated (PPGI)

Pre-Painted Steel Coil/ Color-Coated (PPGI)

-

Galvanized Steel Pipe

Galvanized Steel Pipe

-

Hot Rolled Steel (Coils)/ Plates /Sheet

Hot Rolled Steel (Coils)/ Plates /Sheet

-

Hot Rolled Steel Square Bar

Hot Rolled Steel Square Bar

-

Seamless Steel Pipe

Seamless Steel Pipe

-

Plate Flange

Plate Flange