High Hardness Cold Rolled Steel Coils

The high hardness cold rolled steel coils are produced by rolling the hot rolled pickled coils continuously at room temperature. Generally, the finished product should be processed through flattening, stretching and straightening, edge cutting, etc. Whether the product needs to be oiled depends on the requirements in the contract. We often deliver the product in coil form.

Product Features

Because there is no annealing treatment, the hardness of the product is very high with the HRB larger than 90. Due to the poor machining property, the product can be taken for simple directional bending processing with the angle less than 90 degrees. The bending direction is perpendicular to the winding direction.

Application Range

1. The high hardness cold rolled steel coil can be processed with annealing to manufacture the ordinary cold rolled product.

2. It can also be employed for producing the galvanized plate through the galvanizing unit with device for treatment before annealing.

3. The product is also suitable for use as the panel almost no needing processing.

Delivery Condition

The product is delivered in cold rolled unannealed state.

| Specification | 0.18mm-3.0mm in thickness and 800mm-2000mm in width |

| Material | SPCC |

Note: If the follow-up process relates to ordinary cold rolled based material, then the material can be SPCD, SPCE, ST12, ST13, ST14, ST15, ST16, BLC, BLD, BUSD, BUFD, etc.

Related Names

Wear Resistant Steel Sheet | Precision Metal Processing | Annealed Steel

Links:https://www.globefindpro.com/products/83449.html

-

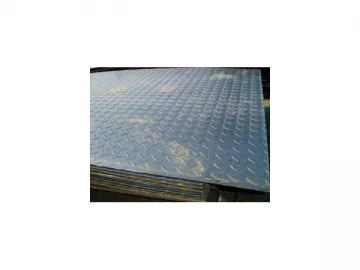

Hot Rolled Chequered Plate

Hot Rolled Chequered Plate

-

Hot Rolled Flat Steel /Steel Flat Bar

Hot Rolled Flat Steel /Steel Flat Bar

-

Groove Steel Flange

Groove Steel Flange

-

Electro-Galvanized Steel Sheet

Electro-Galvanized Steel Sheet

-

Hot Rolled Steel Round Bar

Hot Rolled Steel Round Bar

-

SSAW Steel Pipe, Spiral Submerged Arc Welded Pipe

SSAW Steel Pipe, Spiral Submerged Arc Welded Pipe

-

I Beam

I Beam

-

Iron Ore

Iron Ore

-

PX-999 Tri-Band Radio Transceiver

PX-999 Tri-Band Radio Transceiver

-

Hot Rolled Steel Strip

Hot Rolled Steel Strip

-

ERW Steel Pipe, Electric Resistance Welded Pipe

ERW Steel Pipe, Electric Resistance Welded Pipe

-

Steel Billet

Steel Billet