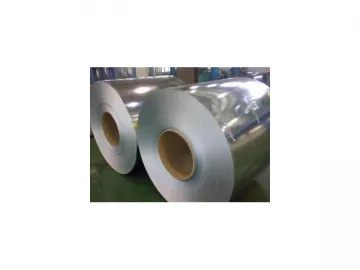

Electro-Galvanized Steel Sheet

Brief Introduction

The electro-galvanized steel sheet is manufactured by firstly going through the rolling via the cold continuous rolling unit, annealing treatment via the CAPL unit, and then getting to the electro-galvanizing unit for surface cleaning. Under the action of electric field, the zinc deposits onto the surface of the steel strip from the zinc salt solution to form the surface zinc coating.

The continuous electro-galvanized cold rolled steel plate and steel strip are fit for the industries covering automobile, electronics, home appliance, etc. The main delivery mode is the coil form product. The steel plate and steel strip through transverse or longitudinal shearing can also be available.

Uses

The electro-galvanized steel sheet can be processed with phosphating, passivation, oiling, fingerprint resistance, alloying, etc. Its mechanical property refers to the corresponding base plate.

Use and Grade (table 1)

| Use | Grade | Applicable Standard | Standard (Q/BQB420) and Grade of Base Plate |

| General use | SECC | Q/BQB 430 | SPCC |

| Drawing | SECD | Q/BQB 430 | SPCD |

| Deep drawing | SECE | Q/BQB 430 | SPCE |

| Fingerprint Resistance | SECC N2SECC N4 | BJZ 434 | SPCC |

Product Variety and Code (table 2)

| Classification | Subdivision | Grade | Grade of Base Plate | Standard of Base Plate |

| Steel for drawing | Steel with low yield point | BLCE Z, BLCE ZN | BLC | Q/BQB 408-1999 |

| BLDE Z, BLDE ZN | BLD | |||

| Steel for non aging super deep drawing | BUSDE Z, BUSDE ZN | BUSD | ||

| BUFDE Z, BUFDE ZN | BUFD | |||

| BSUFDE Z, BSUFDE ZN | BSUFD | |||

| High strength steel for cold forming | Steel for cold forming | B240ZKE Z, B240ZKE ZN | B240ZK | Q/BQB 418-1999 |

| B280VKE Z, B280VKE ZN | B280VK | |||

| B340VKE Z, B340VKE ZN | B340VK | |||

| B400VKE Z, B400VKE ZN | B410VK | |||

| Dent resistance steel | Ultra low carbon steel containing phosphorus | B170P1E Z, B170P1E ZN | B170P1 | Q/BQB 409-1999 |

| B210P1E Z, B210P1E ZN | B210P1 | |||

| B250P1E Z, B250P1E ZN | B250P1 | |||

| Low carbon steel containing phosphorus | B210P2E Z, B210P2E ZN | B210P2 | ||

| B250P2E Z, B250P2E ZN | B250P2 | |||

| B280P2E Z, B280P2E ZN | B280P2 | |||

| Ultra low carbon bake hardened steel | B140H1E Z, B140H1E ZN | B140H1 | ||

| B180H1E Z, B180H1E ZN | B180H1 | |||

| Low carbon bake hardened steel | B180H2E Z, B180H2E ZN | B180H2 | ||

| B210H2E Z, B210H2E ZN | B210H2 | |||

| B250H2E Z, B250H2E ZN | B250H2 |

Product Grade and Standard (table 3)

| Variety | Standard | Category | Grade | Purpose and Characteristic |

| Electro galvanizing | Q/BQB431-2000 | Electro galvanized steel strip | BLCE Z, BLDE Z, BUSDE Z, BUFD Z, BSUFDE Z, B240ZKE Z, B280VKE Z, B340VKE Z, B400VKE Z, B170P1E Z, B210P1E Z, B250P1E Z, B210P2E Z, B250P2E Z, B280P2E Z, B140H1E Z, B180H1E Z, B180H2E Z, B210H2E Z, B250H2E Z | This kind of electro-galvanized steel sheet has the type for drawing and high strength cold forming, as well as the dent resistance type. Through the electro galvanizing, the anticorrosion ability is raised significantly. |

| Electro galvanized nickel alloy steel strip | BLCE ZN, BLDE ZN, BUSDE ZN, BUFDE ZN, BSUFDE ZN, B240ZKE ZN, B280VKE ZN, B340VKE ZN, B400VKE ZN, B170P1E ZN, B210P1E ZN, B250P1E ZN, B210P2E ZN, B250P2E ZN, B280P2E ZN, B140H1E ZN, B180H1E ZN, B180H2E ZN, B210H2E ZN, B250H2E ZN | The product falls into the type for drawing and high strength cold forming, as well as the dent resistance type. Its anticorrosion capability is five times stronger than that of pure zinc coated product with the coating of the same thickness. |

Surface Treatment Classification (table 4)

| Surface Treatment Type | Mark | Use | Description |

| Phosphating | P | Painting | Phosphating mainly makes surface preparation for the following painting and also plays the function of eradicating the generation of the white rust on the surface. |

| Chromatizing | C | General use | Chromatizing is mainly for preventing the generation of white rust during the transportation and storage process. |

| Oiling | O | Pretreatment plus coating | Oiling process is also the effective measure for preventing the product from the white rust. |

| Fingerprint resistance | N | Electrical appliance | This measure can boost the fingerprint resistance and anticorrosion ability. |

Note: The surface treatment mark can combine with the grade arbitrarily, such as SECC-P, SECD-N, SECE-O, etc.

Surface Treatment Type and Characteristics (table 5)

| Surface Treatment Type | Code | Characteristics |

| Chromate processing | C | Good anticorrosion capability and suitable for bare state |

| Chromate processing oiling | S | Excellent corrosion resistance |

| Phosphating processing (including sealing process) | P | Certain corrosion resistance and good performance for painting |

| Phosphating processing (including sealing process) oiling | Q | Certain anticorrosion ability, good performance for painting as well as rust protection during transportation and storage |

| Phosphating processing (without sealing process) | T | Certain corrosion resistance and good performance for painting |

| Phosphating processing (without sealing process) oiling | V | Certain corrosion resistance, good performance for painting and rust protection |

| Oiling | O | Rust prevention during transportation and storage |

| No processing | M | Suitable for painting immediately |

Weight of Zinc Coating (table 6)

| Standard Galvanized Quantity (Single Side) g/m² | Min. Galvanized Quantity for Single Side g/m² | Thickness of Zinc Coating (Single Side) um | ||

| Equal Coating | Differential Coating | Standard Value | ||

| 10 | 8.5 | 8.0 | 10 | 1.4 |

| 20 | 17 | 16 | 20 | 2.8 |

| 30 | 25.5 | 24 | 30 | 4.2 |

| 40 | 34 | 32 | 40 | 5.6 |

| 50 | 42.5 | 40 | 50 | 7.0 |

| 60 | 51.0 | 48 | 60 | 8.4 |

| 70 | 59.5 | 56 | 70 | 9.8 |

| 80 | 68 | 64 | 80 | 11.2 |

Available Specification Range (table 7)

| Item | Nominal Dimension (mm) | |

| Thickness | 0.5-2.0 | |

| Width | 900-1550 | |

| Length | Steel plate | 1000-6000 |

| Steel strip | Inside diameter of 610 | |

Variety of Our Product

| Available material | SECC, SECD, SECE, etc. |

| Available specification | 0.2mm-1.5mm in thickness and 700mm-1530mm in width |

| Quality standard | Enterprise standard, Chinese standard, JIS, DIN, ASTM |

| Available manufacturer | Anshan Iron and Steel Group Corporation, Tangshan Iron and Steel, Shougang Group, Han-Steel of Hebei Iron and Steel Group, Baotou Iron and Steel (Group) |

| Delivery area | Tianjin, Beijing, Wuxi, Qingdao, Jinan, Guangzhou, Tangshan, Shijiazhuang |

Related Names

Zinc Coating Steel Wholesale | Electrolysis Surface Protection | Corrosion Resistant Steel

Links:https://www.globefindpro.com/products/83453.html

-

Hot Rolled Steel Round Bar

Hot Rolled Steel Round Bar

-

SSAW Steel Pipe, Spiral Submerged Arc Welded Pipe

SSAW Steel Pipe, Spiral Submerged Arc Welded Pipe

-

H-beam

H-beam

-

Engineered Wood Veneer Edge Banding

Engineered Wood Veneer Edge Banding

-

EV White Apricot

EV White Apricot

-

Adaptor for Handheld Transceiver

Adaptor for Handheld Transceiver

-

Groove Steel Flange

Groove Steel Flange

-

Hot Rolled Flat Steel /Steel Flat Bar

Hot Rolled Flat Steel /Steel Flat Bar

-

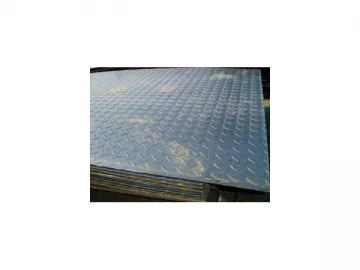

Hot Rolled Chequered Plate

Hot Rolled Chequered Plate

-

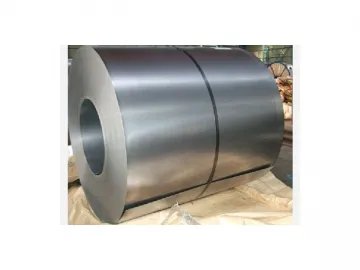

High Hardness Cold Rolled Steel Coils

High Hardness Cold Rolled Steel Coils

-

I Beam

I Beam

-

Iron Ore

Iron Ore