Steel Stud and Track Forming Machine

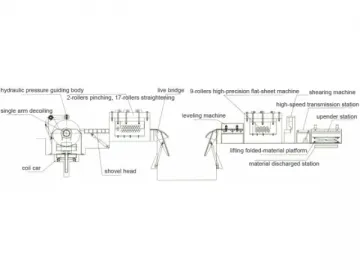

Machine Components

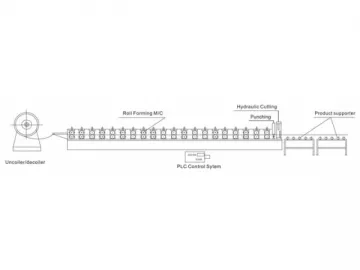

Our steel stud and track forming machine is composed of uncoiler and its base, coil sheet guiding and adjusting device, roll forming system, hydraulic post-cutting system, Mitsubishi PLC variable-frequency control system, run-out table, as well as the selectable punching system.

With high working efficiency, this machine offers the product molding speed of up to 20m per minute. By means of the replacement of punching die, our machine is able to finish different sizes of punched holes. If required by our clients, many specifications of products can be produced by regulating the rollers.

Our steel stud and track forming machine can realize automatically and manually controlled operation. The touch screen adds convenience for use. Raw material of the forming die is 45# steel processed by quenching treatment. The hardness is HRC56-62℃.

Work Flow

Main Technical Parameters

| Suitable Thickness of Raw Material | 0.3-0.8mm |

| Forming Speed | About 15-20m/min |

| Cutter Materials | Cr12 with quenched treatment, HRC58-62 |

| Diameter of Shafts | 55mm |

| Materials of Rollers | High grade 45# Steel with heat treatment |

| Control System | PLC Converter |

| Roller Stands | About 16 stations (as per profiles) |

| Machine Weight | About 4500kg |

| Size of Machine | 6000*1200*1400mm |

Uses

Steel stud and track manufactured by our machine are commonly used for light steel buildings.

Service

A customized roll forming machine is available in our company. That is to say, the machine can be designed by us to comply with the specification and profile drawing given by our clients. Only one profile can be made by one roll forming machine.

Related Names

Wall Stud Production Line Manufacturer | Construction Structure Forming Equipment | Different Size Stud Production

Links:https://www.globefindpro.com/products/83654.html

-

Cut to Length Line

Cut to Length Line

-

C Purlin Forming Machine with Gearbox Drive

C Purlin Forming Machine with Gearbox Drive

-

Single Layer Roof and Wall Panel Forming Machine

Single Layer Roof and Wall Panel Forming Machine

-

Supplementary Machine

Supplementary Machine

-

Steel Shutter Slat Door Forming Machine

Steel Shutter Slat Door Forming Machine

-

C Purlin Forming Machine with Chain Drive

C Purlin Forming Machine with Chain Drive

-

Hydraulic Press Brake

Hydraulic Press Brake

-

Sheet Metal Embossing Machine

Sheet Metal Embossing Machine

-

Z Purlin Forming Machine

Z Purlin Forming Machine

-

Galvanized Steel Coil

Galvanized Steel Coil

-

LED Advertising Electric Tricycle

LED Advertising Electric Tricycle

-

Fuel Efficient LED Advertising Truck

Fuel Efficient LED Advertising Truck