Cut to Length Line

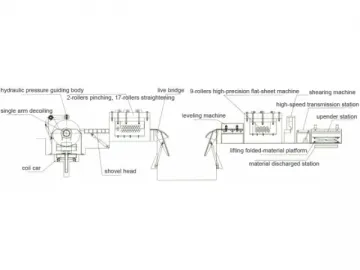

This cut to length line offers such functions as uncoiling, leveling, measuring, cross-cutting to length, as well as stacking. It gives wide applications in cold or hot rolled carbon steel, tinplate, stainless steel, as well as other sorts of metallic materials with surface coating.

Main components of our cut to length line include uncoiler, leveler, measurement encoder, shearer, conveyor, stacker, hydraulic system, pneumatic system, electrical system, and some others. This whole line is controlled by NC servo system. Our PLC system is used to control the length measurement. Inside this system, there is such information as length, speed, and shearing numbers. Once the required shearing number is achieved, this line will stop automatically. The line speed is adjustable. The high-precision encoder allows the whole line to work automatically and operate easily. Furthermore, the sheet can be made smooth.

Service

After the equipment is delivered, it will give a one-year quality guarantee. If its component is damaged out of the quality assurance date, we can provide clients with our customized service and only charges the cost price. Moreover, we offer a lifetime free technical support. No fee will be charged, if our onsite service is not needed. We hope that customers can feel at ease to buy our cut to length line.

Machine Components

Our cut to length line is mainly composed of decoiler, feeding, clamp, leveling device, cut to length equipment, shear machine, automatic stacker, and control system.

Steel Sheet Parameters

| Suitable Materials | Hot rolled steel place, cold rolled steel plate, and galvanized steel plate, among others |

| Thickness | 0.3-30mm |

| Cutting Accuracy | /-0.5mm |

| Width | 600-2500mm |

| Yield Strength | ≤ 350MPa |

| Speed | 60m -80m /min (adjustable) |

| Cutting Length | 3000-12000mm |

Related Names

Steel Uncoiling Equipment Manufacturer | Steel Leveler | Metal Cutting Machine

Links:https://www.globefindpro.com/products/83655.html

-

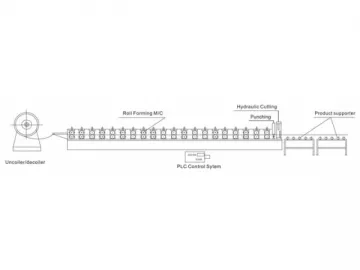

C Purlin Forming Machine with Gearbox Drive

C Purlin Forming Machine with Gearbox Drive

-

Single Layer Roof and Wall Panel Forming Machine

Single Layer Roof and Wall Panel Forming Machine

-

Supplementary Machine

Supplementary Machine

-

Steel Shutter Slat Door Forming Machine

Steel Shutter Slat Door Forming Machine

-

C Purlin Forming Machine with Chain Drive

C Purlin Forming Machine with Chain Drive

-

Steel T Bar Forming Machine

Steel T Bar Forming Machine

-

Steel Stud and Track Forming Machine

Steel Stud and Track Forming Machine

-

Hydraulic Press Brake

Hydraulic Press Brake

-

Sheet Metal Embossing Machine

Sheet Metal Embossing Machine

-

Z Purlin Forming Machine

Z Purlin Forming Machine

-

Galvanized Steel Coil

Galvanized Steel Coil

-

LED Advertising Electric Tricycle

LED Advertising Electric Tricycle