C Purlin Forming Machine with Gearbox Drive

Machine Components

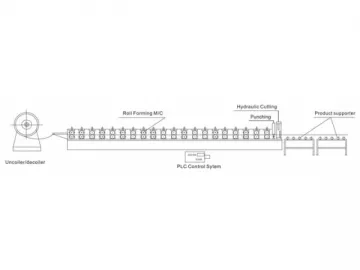

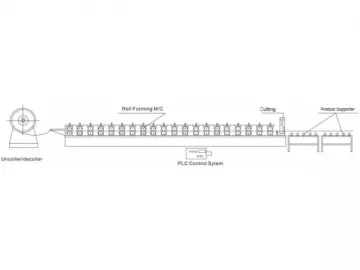

Our C purlin forming machine with gearbox drive is formed by uncoiler and its base, coil sheet guiding and adjusting device, roll forming system, hydraulic post-cutting system, PLC control system, run-out table, as well as the optional hole-punching system.

This machine takes advantage of gearbox drive system, thus increasing both operation reliability and transmitted power. Our equipment plays a role in producing the C shape purlins of different sizes from C80 to C300. Moreover, it is equipped with PLC control system with high degree of automation, which can improve the production accuracy. During normal production, the multilevel security is available. Our product can achieve the operation under both automatic and manual control. The operation using touch screen offers much convenience for users.

The forming die is made from GCr15 or Cr12, which is also subjected to quenching process. The hardness is HRC56-62℃.

Work FlowMain Technical Parameters

| Raw Material Thickness | From 1.6- 4.5mm |

| Materials Strength | ≤ 350MPa |

| Forming Speed | About 10-15m/min |

| Purlin Size | All types from C80 to C300 |

| Roller Materials | Cr12, GCr15 or D2 with heat treatment |

| Power | 32kW 7.5kW (according to finial design) |

| Driving System | Gear box |

| Control System | PLC |

| Roller Stands Qty. | Main 15 stands |

| Machine Size | 11500*1200*1500mm |

| Electricity Requirements | 380V, 3 phase, 50Hz or as per buyer' s requirements |

Product Samples Picture

C Purlin Size

a: (80-300mm)

b: (40-80mm)

c: (10-20mm)

t: 1.5-3.2mm

Various sizes are available, such as C100*40*15, C120*50*20, C160*60*20 C200*70*20, C240*80*20. Both punching and sizes accord with customer requirements.

Applications

C purlin made by C purlin forming machine with gearbox drive can function as steel roof and wall frame system.

Service

Additionally, our company also provides a customized roll forming machine. That is to say, the machine can be designed by our company in compliance with the specification and profile drawing given by our customers. We give the PDF profile drawings as some examples for reference.

| No. | A | B | C | T | L | Coil Width | Remark |

| C1 | 80 | 40 | 15 | 3.0 | 172 | O | |

| C2 | 100 | 40 | 15 | 3.0 | 40 | 192 | √ |

| 100 | 50 | 20 | 3.0 | 40 | 222 | √ | |

| 100 | 60 | 20 | 3.0 | 40 | 242 | √ | |

| C3 | 120 | 50 | 20 | 3.0 | 50 | 242 | √ |

| 120 | 60 | 20 | 3.0 | 50 | 262 | √ | |

| C4 | 140 | 50 | 20 | 3.0 | 60 | 262 | √ |

| 140 | 60 | 20 | 3.0 | 60 | 282 | √ | |

| C5 | 160 | 60 | 20 | 3.0 | 80 | 302 | √ |

| 160 | 70 | 20 | 3.0 | 80 | 322 | √ | |

| C6 | 180 | 60 | 20 | 3.0 | 100 | 322 | √ |

| 180 | 70 | 20 | 3.0 | 100 | 342 | √ | |

| C7 | 200 | 60 | 20 | 3.0 | 120 | 342 | √ |

| 200 | 70 | 20 | 3.0 | 120 | 362 | √ | |

| C8 | 220 | 70 | 20 | 3.0 | 120 | 382 | √ |

| 220 | 80 | 20 | 3.0 | 120 | 402 | √ | |

| C9 | 240 | 70 | 20 | 3.0 | 120 | 402 | √ |

| 240 | 80 | 20 | 3.0 | 120 | 422 | √ | |

| C10 | 250 | 80 | 20 | 3.0 | 120 | 432 | O |

Related Names

Different Size Purlin Making Device Manufacturer | Roofing Truss Production Line | Roof Profile Roll Forming Equipment

Links:https://www.globefindpro.com/products/83656.html

-

Single Layer Roof and Wall Panel Forming Machine

Single Layer Roof and Wall Panel Forming Machine

-

Supplementary Machine

Supplementary Machine

-

Steel Shutter Slat Door Forming Machine

Steel Shutter Slat Door Forming Machine

-

C Purlin Forming Machine with Chain Drive

C Purlin Forming Machine with Chain Drive

-

Steel T Bar Forming Machine

Steel T Bar Forming Machine

-

Corrugated Sheet Roll Forming Machine

Corrugated Sheet Roll Forming Machine

-

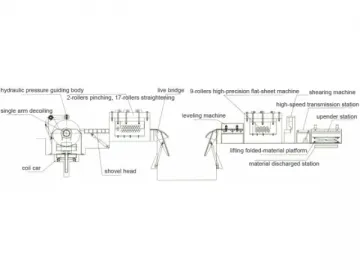

Cut to Length Line

Cut to Length Line

-

Steel Stud and Track Forming Machine

Steel Stud and Track Forming Machine

-

Hydraulic Press Brake

Hydraulic Press Brake

-

Sheet Metal Embossing Machine

Sheet Metal Embossing Machine

-

Z Purlin Forming Machine

Z Purlin Forming Machine

-

Galvanized Steel Coil

Galvanized Steel Coil