Single Layer Roof and Wall Panel Forming Machine

Machine Components

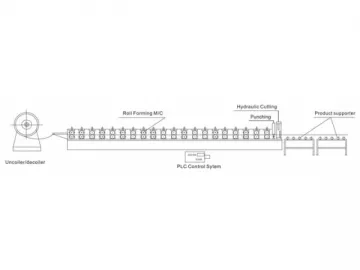

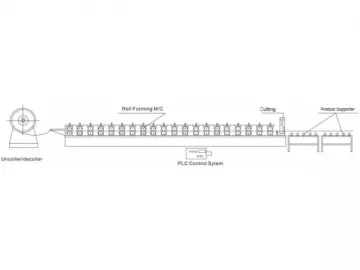

This single layer roof and wall panel forming machine is controlled by PLC system, which is also designed with multiple security protectors. It is able to realize automatically and manually controlled equipment operation. Owing to the touch screen, our product can be operated easily by our users. The forming die is constructed from 45# steel material with the hardness of HRC56-62℃.

Main components of this machine include the uncoiler, PLC control system, support table, hydraulic station, cutting device, coil sheet guiding device, as well as the main roll foaming system.

Main Technical Parameters

| Suitable Material | Color steel sheet or galvanized steel sheet |

| Thickness of Raw Material | 0.3-0.9mm |

| Yield Strength of Material | 235MPa |

| Forming Speed | About 15m-20/min |

| Main Motor Power | 5.5kW (Depend on final design) |

| Hydraulic Station Power | 2.2kW (Depend on final design) |

| Max. Loading Capacity of Uncoiler | 5000kg (can be increased to be 10T) |

| Control System | Mitsubishi PLC and converter |

| Machine Size | About 20m×1.5m×1.4m (Depend on final design) |

Profiles and Product Samples

| Item No. | Coil Width /Cover Width | Profile and Sample |

| FDYX25-205-1025 | 1200mm 1025mm | |

| FDYX18-76-836 | 1200mm 950mm | |

| FDYX24-210-840 | 1000mm 840mm | |

| FDYX35-125-750 | 1000mm 750mm | |

| FDYX41-210-420 | 600mm 420mm | |

| FDYX66-470 | 600mm 470mm | |

| FDYX80-212-609 | 914mm 609mm | |

| FDYX75-380-760 | 1000mm 760mm |

Product Samples Picture

Service

The customized roll forming machine is available. We can design this equipment, based on the specifications or profile drawings from our customers. One roll forming machine only gives one profile. We provide some examples about the profile drawings for reference.

Related Names

China Wall Panel Forming Equipment | Automatic Roof Sheet Production | Steel Roofing Tile Making System

Links:https://www.globefindpro.com/products/83657.html

-

Supplementary Machine

Supplementary Machine

-

Steel Shutter Slat Door Forming Machine

Steel Shutter Slat Door Forming Machine

-

C Purlin Forming Machine with Chain Drive

C Purlin Forming Machine with Chain Drive

-

Steel T Bar Forming Machine

Steel T Bar Forming Machine

-

Corrugated Sheet Roll Forming Machine

Corrugated Sheet Roll Forming Machine

-

Trapezoid Roofing Roll Forming Machine

Trapezoid Roofing Roll Forming Machine

-

C Purlin Forming Machine with Gearbox Drive

C Purlin Forming Machine with Gearbox Drive

-

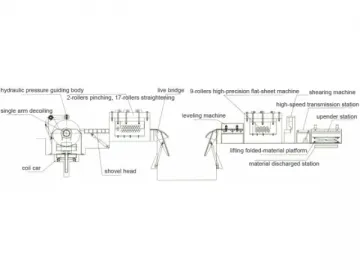

Cut to Length Line

Cut to Length Line

-

Steel Stud and Track Forming Machine

Steel Stud and Track Forming Machine

-

Hydraulic Press Brake

Hydraulic Press Brake

-

Sheet Metal Embossing Machine

Sheet Metal Embossing Machine

-

Z Purlin Forming Machine

Z Purlin Forming Machine