Corrugated Sheet Roll Forming Machine

Machine Components

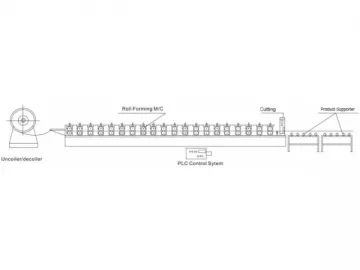

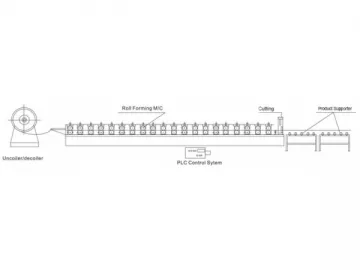

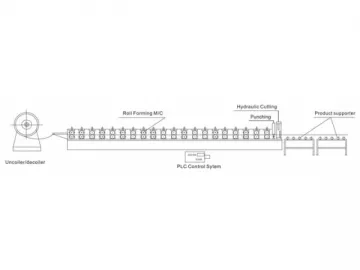

Our corrugated sheet roll forming machine is composed of uncoiler, cutting device, hydraulic station, PLC control system, main roll forming system, coil sheet guiding device, as well as support table. In normal production process, multiple protective functions are offered for better security. The equipment operation can realize fully automatic and manual control. The touch-screen operation provides much convenience for use.

In use of this corrugated sheet roll forming machine, the colored steel sheet can be rolled to form the required shape of metal sheet at room temperature. Generally, the raw material of our product comes from different colors of steel sheets or the galvanized steel sheet with the thickness range from 0.6 to 0.9mm. In this way, all sorts of household or industrial door frames can be produced. Moreover, our machine adopts Mitsubishi PLC variable-frequency control system. Its transmission structure is chain, characterized by easy operation and high reliability. The forming die is constructed from GCr15 or Cr12 with quenching treatment. The hardness is HRC56-62℃.

Main Technical Parameters

| Suitable Material | Color steel sheet or galvanized steel sheet |

| Thickness of Raw Material | 0.3-0.9mm |

| Yield Strength of Material | 235Mpa |

| Forming Speed | About 15m-20/min |

| Main Motor Power | 5.5kW (Depend on final design) |

| Hydraulic Station Power | 2.2 kW (Depend on final design) |

| Maximum Loading Capacity of Uncoiler | 5000kg (can be increased to 10t) |

| Control System | Mitsubishi PLC and converter |

| Machine Size | About 20m×1.5m×1.4m (Depend on final design) |

Product Samples Picture

Service

We can design the roll forming machine in accordance with the specification and profile drawing of our customers. Each machine only can finish one profile. The following profile drawings are given as some examples for reference.

Related Names

Metal Sheet Making Machine | Corrugated Iron Forming Equipment | Different Thickness Steel Sheet Processing

Links:https://www.globefindpro.com/products/83663.html

-

Trapezoid Roofing Roll Forming Machine

Trapezoid Roofing Roll Forming Machine

-

Metal Crimping Roll Forming Machine

Metal Crimping Roll Forming Machine

-

Highway Guardrail Forming Machine

Highway Guardrail Forming Machine

-

Slitting Machine Line

Slitting Machine Line

-

Sheet Metal Shearing Machine

Sheet Metal Shearing Machine

-

Roll Shutter Door Forming Machine

Roll Shutter Door Forming Machine

-

Steel T Bar Forming Machine

Steel T Bar Forming Machine

-

C Purlin Forming Machine with Chain Drive

C Purlin Forming Machine with Chain Drive

-

Steel Shutter Slat Door Forming Machine

Steel Shutter Slat Door Forming Machine

-

Supplementary Machine

Supplementary Machine

-

Single Layer Roof and Wall Panel Forming Machine

Single Layer Roof and Wall Panel Forming Machine

-

C Purlin Forming Machine with Gearbox Drive

C Purlin Forming Machine with Gearbox Drive