Down Pipe Forming Machine

Machine Components

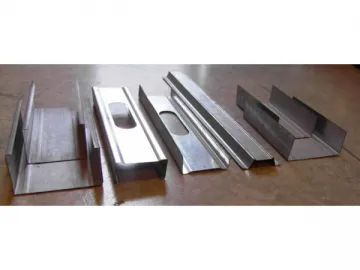

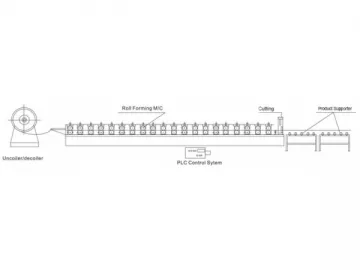

This down pipe forming machine incorporates decoiler, roll forming system, cutting device, protective guard, hydraulic system, automatic control system, as well as product supporter. It is extensively used for steel buildings, villas, and other water pipeline.

Our down pipe forming machine utilizes the color steel plate to form the closed type color steel down pipe by adoption of cold-roll forming and automatic locksewing technique. This machine also comes with PLC control and alternating-current variable-frequency speed control technology. It can realize the automatic fixed-length cutting, which is the original color steel down pipe dedicated equipment in China.

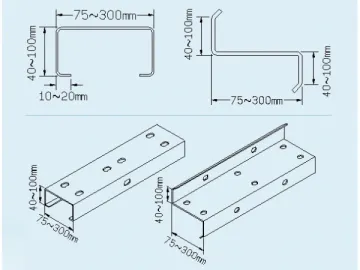

This series equipment is ideal for the bending and necking of color steel down pipes. The whole machine is controlled by the cam to achieve the automatic production. The bending angle can be adjusted manually. In accordance with user requirements, the machine for various types of plates can be designed.

Work FlowMain Technical Parameters

| Suitable Raw Material | 0.4~0.55mm color steel sheet |

| Main Motor Power | 5.5kW |

| Hydraulic Power | 7.5kW (Depend on final design) |

| Forming Speed | About 10-15m/min |

| Control System | Mitsubishi PLC and converter |

| Material of Cutting Die | Cr12 mold steel with quench treatment |

| Dimension of Machine | About 16000mm×1100mm×1200mm |

Service

A customized roll forming machine can be done by our company. That is to say, we can design the machine on basis of the specification and profile drawing provided by our clients. Only one profile can be produced by each machine.

Related Names

Downspout Making Equipment Manufacturer | Waterspout Production Line | Roof Drain Pipe Making Machinery

Links:https://www.globefindpro.com/products/83672.html

-

Door Frame Forming Machine

Door Frame Forming Machine

-

Pressing and Bending Machine

Pressing and Bending Machine

-

Drywall Frame Forming Machine

Drywall Frame Forming Machine

-

Interchange C and Z Purlin Forming Machine

Interchange C and Z Purlin Forming Machine

-

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine

-

7031 Adjustable Temperature Hair Straightener

7031 Adjustable Temperature Hair Straightener

-

Roll Shutter Door Forming Machine

Roll Shutter Door Forming Machine

-

Sheet Metal Shearing Machine

Sheet Metal Shearing Machine

-

Slitting Machine Line

Slitting Machine Line

-

Highway Guardrail Forming Machine

Highway Guardrail Forming Machine

-

Metal Crimping Roll Forming Machine

Metal Crimping Roll Forming Machine

-

Trapezoid Roofing Roll Forming Machine

Trapezoid Roofing Roll Forming Machine