Door Frame Forming Machine

Machine Components

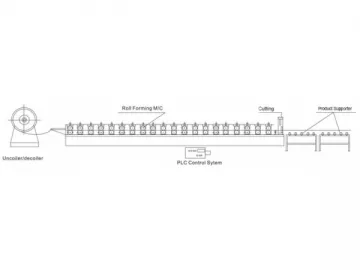

Our door frame forming machine incorporates uncoiler, hydraulic system, cutting system, PLC control system, guiding device, roll forming system, as well as the support table. In normal production, multiple protective functions are available to ensure safety. The equipment operation is controlled automatically and manually. By utilizing touch screen, it is really convenient for our users.

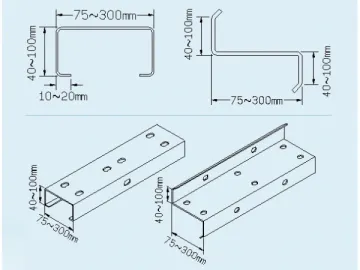

The raw material of colored steel sheet can be rolled to form the required shape of metal sheet at room temperature. Generally, different colors of steel sheet or the galvanized steel sheet with its thickness from 0.6 to 0.9mm is used as the raw material. Then, all kinds of household or industrial door frames can be made.

Our door frame forming machine is equipped with Mitsubishi PLC variable-frequency control system. Its transmission structure is chain, featuring easy and stable operation. The forming die is made from GCr15 or Cr12 with quenching treatment. The hardness reaches HRC56-62℃.

Work Flow

Main Technical Parameters

| Material Thickness | 0.6-0.9mm color steel sheet or galvanized steel sheet |

| Motor Power | 5.5kW 3kW (Depend on final design) |

| Cutter Material | Cr12 mould steel |

| Roller Materials | 45# steel with heat treatment |

| Cutter Materials | Cr12 (HRC 58-62) |

| Shaft Roller | 72mm |

| Drive System | Chain |

| Roller Stations | About 18 stands |

| Forming Speed | 15-20m/min |

| Machine Weight | 6000kg around |

| Machine Size | 8000*1200*1500mm |

| Control System | Mitsubishi PLC and converter |

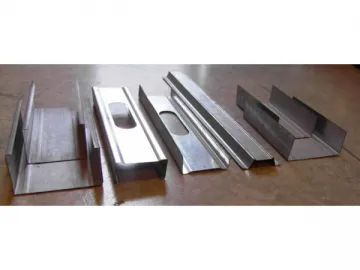

Product Samples Picture

Related Names

Door Frame Forming Equipment Manufacturer | Chain Conveyor Door Profile Making Machine | Industrial Door Structure Making System

Links:https://www.globefindpro.com/products/83673.html

-

Pressing and Bending Machine

Pressing and Bending Machine

-

Drywall Frame Forming Machine

Drywall Frame Forming Machine

-

Interchange C and Z Purlin Forming Machine

Interchange C and Z Purlin Forming Machine

-

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine

-

7031 Adjustable Temperature Hair Straightener

7031 Adjustable Temperature Hair Straightener

-

8111 Countertop Single Zone Induction Cooker

8111 Countertop Single Zone Induction Cooker

-

Down Pipe Forming Machine

Down Pipe Forming Machine

-

Roll Shutter Door Forming Machine

Roll Shutter Door Forming Machine

-

Sheet Metal Shearing Machine

Sheet Metal Shearing Machine

-

Slitting Machine Line

Slitting Machine Line

-

Highway Guardrail Forming Machine

Highway Guardrail Forming Machine

-

Metal Crimping Roll Forming Machine

Metal Crimping Roll Forming Machine