Drywall Frame Forming Machine

Machine Components

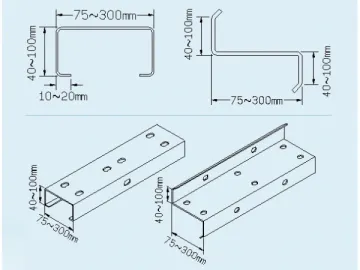

This drywall frame forming machine can accord with various types of ceilings to produce multiple dimensions of drywall frame. The finished drywall frame features flat surface, as well as clear edges and corners. The cut is characterized by nice appearance, high-precision specifications, and light weight but high strength.

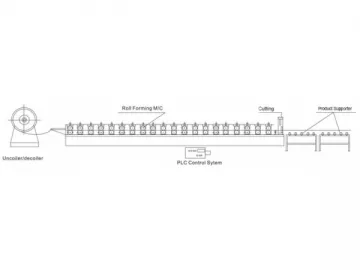

Key components of this kind forming machine incorporates PLC control system, uncoiler and its base, roll forming system, run-out table, hydraulic post-cutting system, coil sheet guiding and adjusting device, as well as the optional punching system.

During normal production, numerous protective measures are taken to better ensure safety. The equipment operation can be controlled either automatically or manually. By utilizing the touch screen, our users feel convenient to operate our drywall frame forming machine. The forming die is made from 45# steel with quenching treatment. The hardness is HRC56-62℃.

Work Flow

Main Technical Parameters

| Suitable Thickness of Raw Material | 0.3-0.8mm |

| Forming Speed | About 15-20m/min |

| Cutter Materials | Cr12 with quenched treatment, HRC58-62 |

| Diameter of Shafts | 55mm |

| Materials of Rollers | High grade 45# Steel with heat treatment |

| Control System | PLC Converter |

| Roller Stands | About 16 stations (as per profiles) |

| Machine Weight | About 4500kg |

| Size of Machine | 6000*1200*1400mm |

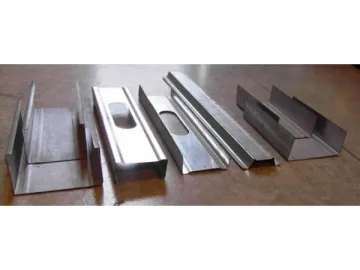

Product Samples Picture

Scope of Application

The drywall is extensively applied in light steel buildings. Our product is widely used for the decoration of indoor suspended ceilings.

We can offer our customized roll forming machine. In other words, the machine design is based on the specification and profile drawing of our customers. Each machine produces only one profile. The PDF profile drawings are provided as some examples for reference.

Related Names

Ceiling Structure Roll Forming Equipment | High Security Level Ceiling Frame Maker | Building Material Production Line

Links:https://www.globefindpro.com/products/83676.html

-

Interchange C and Z Purlin Forming Machine

Interchange C and Z Purlin Forming Machine

-

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine

-

7031 Adjustable Temperature Hair Straightener

7031 Adjustable Temperature Hair Straightener

-

8111 Countertop Single Zone Induction Cooker

8111 Countertop Single Zone Induction Cooker

-

7065 Digital Hair Straightener

7065 Digital Hair Straightener

-

1915 Tabletop Single Zone Induction Cooker

1915 Tabletop Single Zone Induction Cooker

-

Pressing and Bending Machine

Pressing and Bending Machine

-

Door Frame Forming Machine

Door Frame Forming Machine

-

Down Pipe Forming Machine

Down Pipe Forming Machine

-

Roll Shutter Door Forming Machine

Roll Shutter Door Forming Machine

-

Sheet Metal Shearing Machine

Sheet Metal Shearing Machine

-

Slitting Machine Line

Slitting Machine Line