Interchange C and Z Purlin Forming Machine

Characteristics

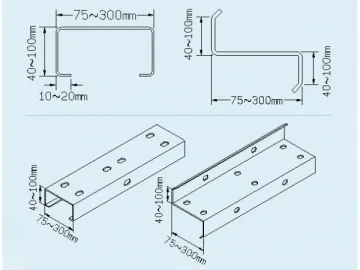

Our interchange C and Z purlin forming machine is able to produce multiple dimensions of C or Z purlins, with no need to change any roller. The height, width and thickness can be adjusted, which are automatically controlled by the computer. The user simply needs to input the required size and press the control button. Then, the equipment will accord with customer requirements to adjust the rollers automatically. The time spent on adjusting rollers is approximately 2 to 3 minutes. Our machine is able to make the surface quite smooth and nice without any scratch.

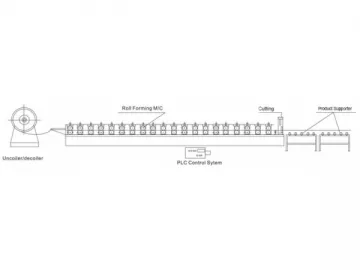

The whole working procedure includes uncoiler, roll-forming, as well as cut-to-length. If required, punching can be also added into this procedure. We give a one-year guarantee for our product. Also, we provide the lifetime free technical support. No cost will be received by us, unless the on-site service is needed. We hope that clients can feel safe to purchase our product.

Composition of Machine Line

Our interchange C and Z forming machine is mainly composed of double-head uncoiler, roll-forming main machine, automatically hydraulic punching system, automatic cut-to-length hydraulic cutting system, as well as the control panel with fully automatic PLC control system.

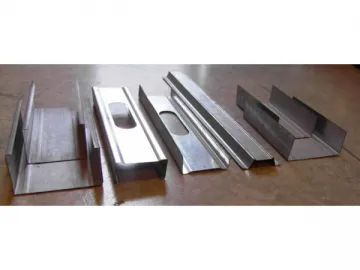

Profile Samples

Related Names

Steel Purline Making Equipment | High Efficiency Purlin Production Line | Purling Maker with Automatic Control System

Links:https://www.globefindpro.com/products/83677.html

-

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine

-

7031 Adjustable Temperature Hair Straightener

7031 Adjustable Temperature Hair Straightener

-

8111 Countertop Single Zone Induction Cooker

8111 Countertop Single Zone Induction Cooker

-

7065 Digital Hair Straightener

7065 Digital Hair Straightener

-

1915 Tabletop Single Zone Induction Cooker

1915 Tabletop Single Zone Induction Cooker

-

5210 PTC Heater Hair Straightener

5210 PTC Heater Hair Straightener

-

Drywall Frame Forming Machine

Drywall Frame Forming Machine

-

Pressing and Bending Machine

Pressing and Bending Machine

-

Door Frame Forming Machine

Door Frame Forming Machine

-

Down Pipe Forming Machine

Down Pipe Forming Machine

-

Roll Shutter Door Forming Machine

Roll Shutter Door Forming Machine

-

Sheet Metal Shearing Machine

Sheet Metal Shearing Machine