Cable Tray Roll Forming Machine

Machine Components

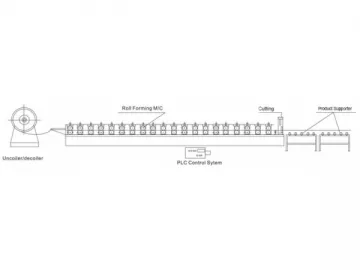

This cable tray roll forming machine contains uncoiler, support table, guiding device, PLC control system, hydraulic system, punching system, cutting system, as well as roll forming system.

This cable tray roll forming machine comes with Mitsubishi PLC variable-frequency control system. It possesses high working efficiency. The product molding speed can reach 20m per minute. By replacing the punching die, our machine is able to meet the need of punched holes of different sizes. Based on customer requirements, the goods of distinct specifications can be made by means of roller adjustment.

This machine can run under fully automatic and manual control. It is used conveniently by adoption of touch screen. The forming die is constructed from 45# steel through quenching process. The hardness is HRC56-62℃.

Work Flow

Uncoiler - feeding - punching - measure length - cutting - feeding - roll forming - run out table

| Material Thickness | 0.5-1mm color steel sheet or galvanized steel sheet |

| Motor Power | 25kW 5.5kW (Depend on final design) |

| Cutter Material | Cr12 mould steel |

| Roller Materials | 45# steel with heat treatment |

| Cutter Materials | Cr12 (HRC 58-62) |

| Profile Width | Adjustable |

| Punching Holes | Continuous punching |

| Drive System | Chain |

| Roller Stations | About 22 stands |

| Forming Speed | 1-20m/min |

| Machine Weight | 15000kg around |

| Machine Size | 18000*1200*1500mm |

| Control System | Mitsubishi PLC and converter |

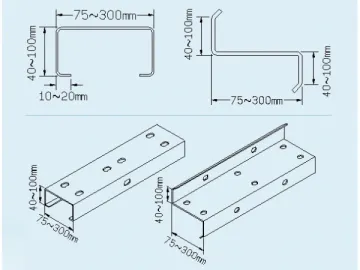

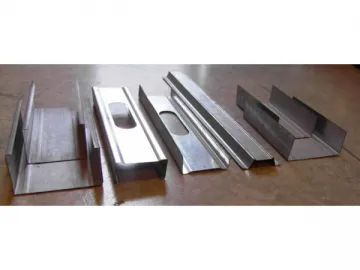

Product Samples Picture

Our cable tray roll forming machine is widely applied in industrial architecture field.

Related Names

Automatic Cable Tray Production Line | Cable Profile System Making Solution | Power Distribution Accessories

Links:https://www.globefindpro.com/products/83679.html

-

7031 Adjustable Temperature Hair Straightener

7031 Adjustable Temperature Hair Straightener

-

8111 Countertop Single Zone Induction Cooker

8111 Countertop Single Zone Induction Cooker

-

7065 Digital Hair Straightener

7065 Digital Hair Straightener

-

1915 Tabletop Single Zone Induction Cooker

1915 Tabletop Single Zone Induction Cooker

-

5210 PTC Heater Hair Straightener

5210 PTC Heater Hair Straightener

-

Induction Water Heater

Induction Water Heater

-

Interchange C and Z Purlin Forming Machine

Interchange C and Z Purlin Forming Machine

-

Drywall Frame Forming Machine

Drywall Frame Forming Machine

-

Pressing and Bending Machine

Pressing and Bending Machine

-

Door Frame Forming Machine

Door Frame Forming Machine

-

Down Pipe Forming Machine

Down Pipe Forming Machine

-

Roll Shutter Door Forming Machine

Roll Shutter Door Forming Machine