GDASY-AE Gravure Printing Machine

This GDASY-AE gravure printing machine is particularly developed for large amount of printing in 2010. This is our latest product at present. It is primarily applied to printing BOPP, CPP, PET, PVC, PVC shrink film, nylon film and other laminated films with the same performance, as well as paper, etc.

Features

1. Without connection between the bases of every two color cells, the product is convenient for customers to load and unload the printing form by trolley. It also saves much time because of its easy operation.

2. Supporting automatic roll changing without halt at high speed operation, the product reduces waste materials.

3. The mechanical speed of the gravure printing machine is 200m per minute and its printing speed reaches 180m every minute.

4. This product has rather strict requirements on the working fields of customers. The floor of the workshop should be built in concrete structure and the thickness is more than 45cm. The working floor must be flat and the horizontal deviation should be controlled no more than 10mm.

Use and Marketing Situation

Mainly adopted in food packaging industry and beverage label industry by large scale enterprises at home and abroad, this gravure printing machine has been already exported to Dubai, Kenya and Brazil. As it gains deep trust of customers because of its excellent performance, Orbit Company in Kenya has ordered three sets of products from our company. Our next object market is focused on South America, India and other places.

Main Configurations

1. Designed without any connecting device on the base, the product is easy for mounting and dismounting.

2. It is equipped with seven-motor drive system, Yaskawa inverter, Siemens PLC and operating interface with dual touching screen.

3. This product adopts automatic tracking color register system and inspection system for still frame, as well as automatic materials connecting and changing device at high speed operation without stop.

4. Without shaft, the gravure printing machine makes use of pneumatic plate mounting system with the help of trolley.

5.The printing mechanism utilizes a pair of pneumatic dual air cylinders and is capable of auto-locking. This system implements a pressure roller which can exercise lifting constraints to enhance the color register and prevent air cylinder leakage.

6. The product is installed with the automatic semi-closed ink circulation system to avoid spattering ink at high speed operation.

7. The doctor blade allows adjusting up and down, even forward and backward. It moves from side to side under the drive of the motor, which cooperates with the inverter.

8. As for the drying system, the gravure printing machine uses the external drying oven for heating with hot air circulating structure. Moreover, the temperature can be controlled intelligently. This product also adopts the pre-heating unit.

9. The cooling system consists of air cooling and water cooling structures and it is used to cool the thin film.

Main Technical Parameters

| Model | GDASY-800AE | GDASY-1000AE | GDASY-1200AE |

| Quantity of color | 8 | 8 | 8 |

| Speed of machine | 200m/min | 200m/min | 200m/min |

| Printing speed | 180m/min | 180m/min | 180m/min |

| Diameter of printing form | φ120mm~φ350mm | φ120mm ~φ350mm | φ120mm~φ350mm |

| Printing width | 800mm | 1000mm | 1200mm |

| Unwinding and rewinding diameter | 800mm | 800mm | 800mm |

| Precision of color register | ±0.12mm | ±0.12mm | ±0.12mm |

| Drying method | Electricity | Electricity | Electricity |

| Total power | 218kw | 228kw | 246kw |

| Overall weight | 29000kw | 30000kw | 31000kw |

| Overall dimension | 21800×3150×3500mm | 21800×3350×3500mm | 21800×3550×3500mm |

Pictures for parts of the machine:

GDASY-AE

7 motor drive system

Auto register and video inspection

Doctor blade

Drying part

GDASY-AE-rewind

GDASY-AE-unwind

Shaft-less cylinder mounting

Related Names

High Speed Gravure Printer Manufacturer | Automatic Gravure Press | PVC Film Gravure Printing Equipment

Links:https://www.globefindpro.com/products/83739.html

-

Pattern Design Color UV MDF

Pattern Design Color UV MDF

-

7062 Adjustable Temperature Hair Straightener

7062 Adjustable Temperature Hair Straightener

-

YN915 High Dump Loader

YN915 High Dump Loader

-

LiFePO4 Rechargeable Batteries

LiFePO4 Rechargeable Batteries

-

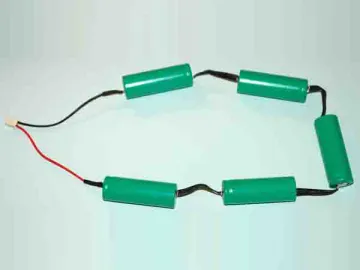

NiMh Battery Packs

NiMh Battery Packs

-

Keystone Slotted Pipe

Keystone Slotted Pipe

-

Matt PVC Edge Banding

Matt PVC Edge Banding

-

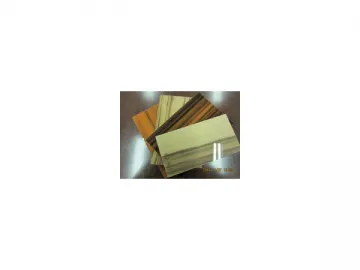

Woodgrain Melamine Faced MDF Board

Woodgrain Melamine Faced MDF Board

-

Woodgrain UV MDF

Woodgrain UV MDF

-

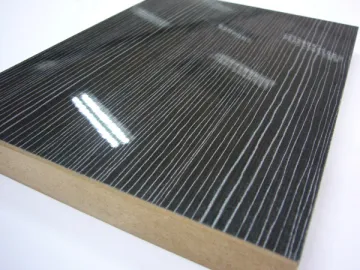

Diamond Face UV MDF

Diamond Face UV MDF

-

YN845 Skid Steer Loader

YN845 Skid Steer Loader

-

Woodgrain Acrylic MDF Board

Woodgrain Acrylic MDF Board